Thanks guys!! Sure is easier to keep motivated now with a car that actually does something other than just sit there. Can’t wait to bring it out to the bash next year under its own power (assuming there is a bash next year).

Since one car has an end in sight.. time to move onto #2. Got the rims and tires mounted over the weekend. Hoping to get that car up on the chassis jig shortly to start chopping.

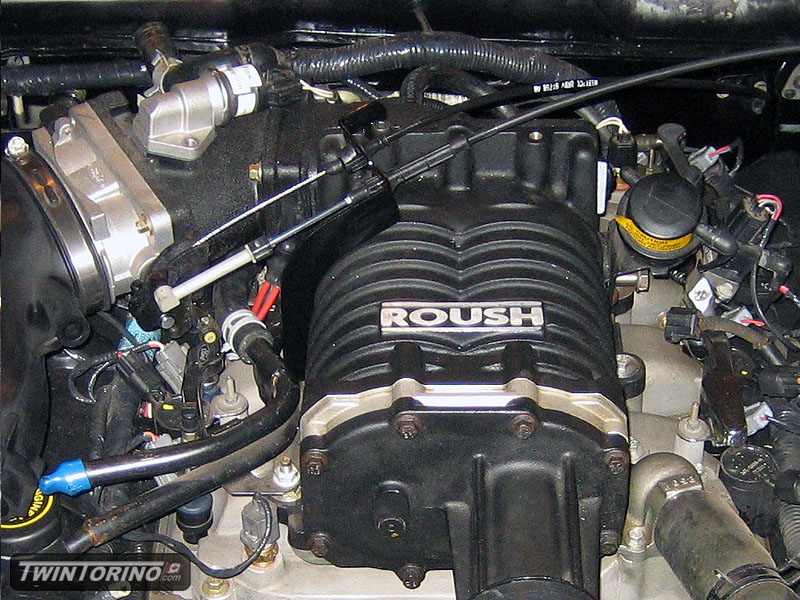

Same tires as the other car – Michelin Pilot Sport Ps2 275/35/18 front, 315/30/18 rear. Rims are forged and from a Roush “Blackjack” edition, with one set narroed for the front.