Category: Fuel

Fuel Lines and More Cooling..

Fuel system is basically done – just need to get Oetiker clamps on the lines and that will be it. Ended up using new Mustang fuel filter and bracket and retained the quick connect fittings. Makes parts cheaper and more readily available too.

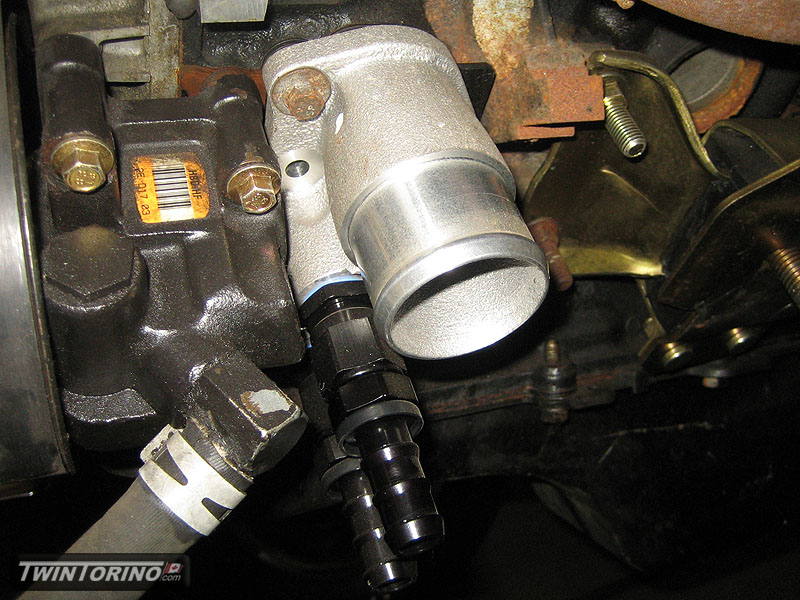

Moving onto cooling system, we have all of the hoses, adapters and fittings. Using the Ford racing oil filter adapter, it makes setting up the coolant hoses and oil cooler system a breeze.

Next step is to get a quick coat of paint on the underbody to keep rust away, and then assemble everything underneath the car. Once we shake down the car, we will send it in for final paint inside and out.

Brakes and Fuel..

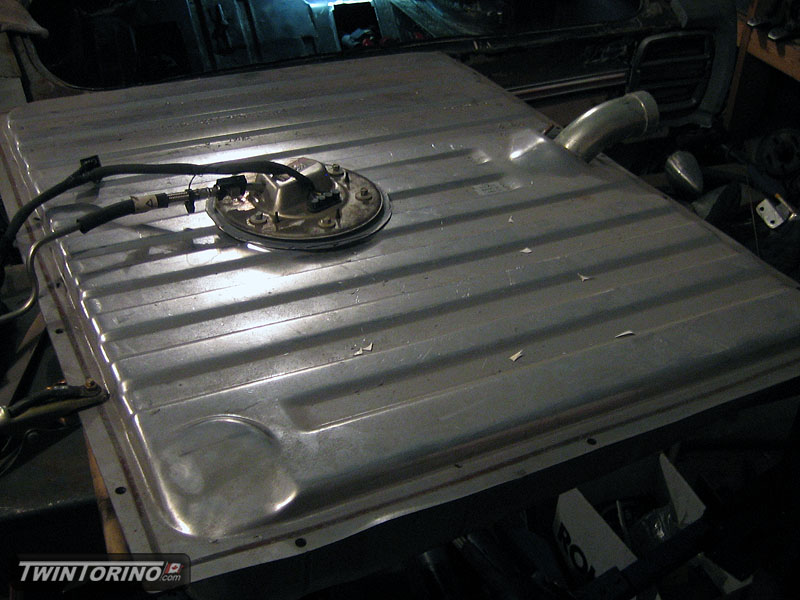

Have not posted in a while.. likely because we have been too busy working on the car. We have the fuel tank almost ready to bolt in, just need to weld on a modern filler neck/cap. The pump reservoir has been welded to the standard Torino gas tank to mimic the setup on a 2004 Mustang Cobra.

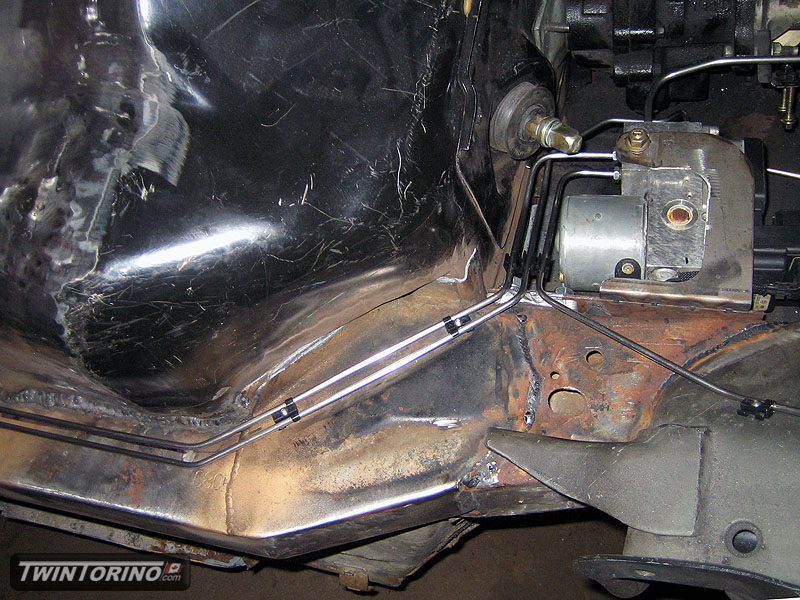

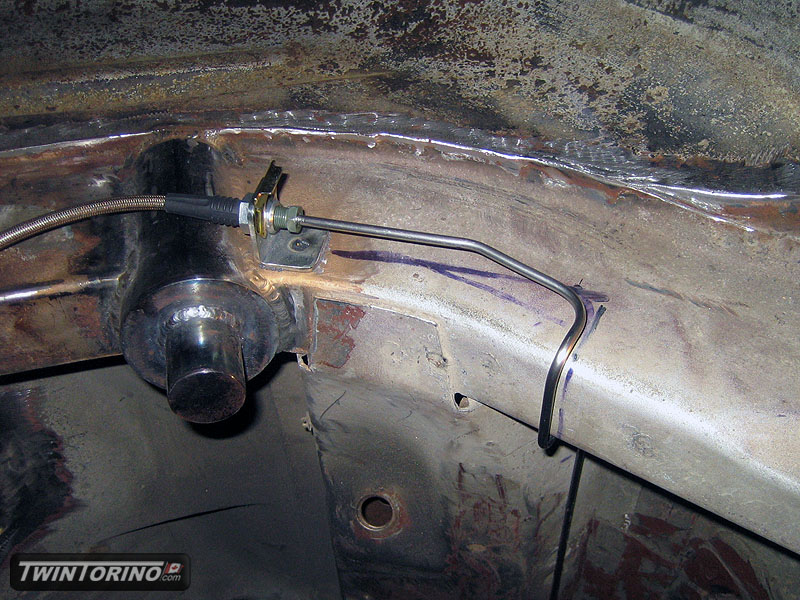

Brake system is for the most part complete, as all the necessary lines are bent up and attached to the car. Once the car is back on the ground, only thing to do now is bleed them.

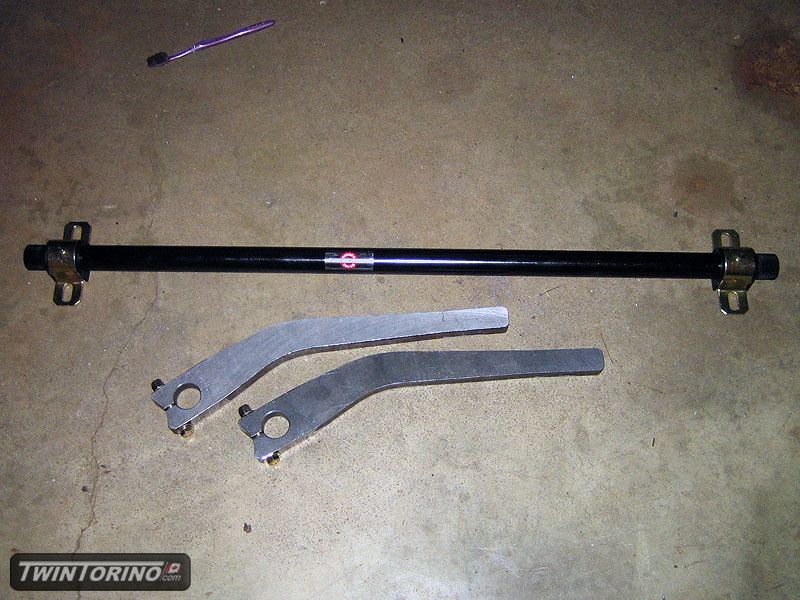

Splined swaybars arrived this week from Speedway – very nice parts. Looks like we are very close to having all the parts we need to complete 1 car – finally.

Wheel Wells, Front Rad X-Member and Fuel Sump

Have not posted in a while.. but getting lots done behind the scenes.

Have the rear wheel wells, shock mounts and spring mounts completed. Pictures shown is with the car upside down. Not much else to do in this area until final paint goes on. Moving onto the front of the car, the new radiator crossmember is welded in for good, and more or less complete (and also shown upside down. Just need to make up a mount to pick up the hood latch support. Only thing left to do under the car now is bend up the 2 rear brake lines and a fuel line.

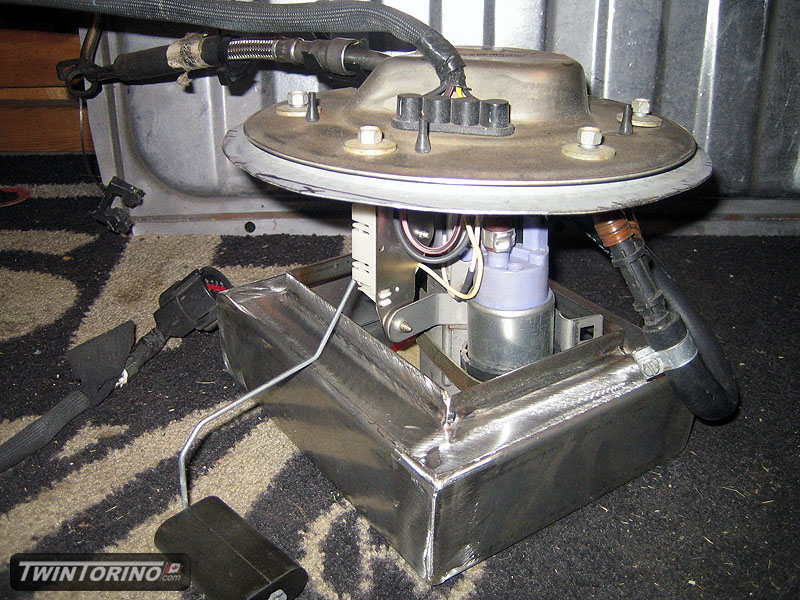

Figured since the car will hopefully be up and running soon, it was time to finish up the fuel system. We made a fuel sump up out of stainless using a 2003/2004 Cobra tank as reference. We still need to add the supply tube and air vent, otherwise it is ready to go in the tank.

Once the lines are done, the car will be put back on its suspension, and the powertrain will go in for the last time for a while, as it is time to get thing thing on the road.

Tank and lines..

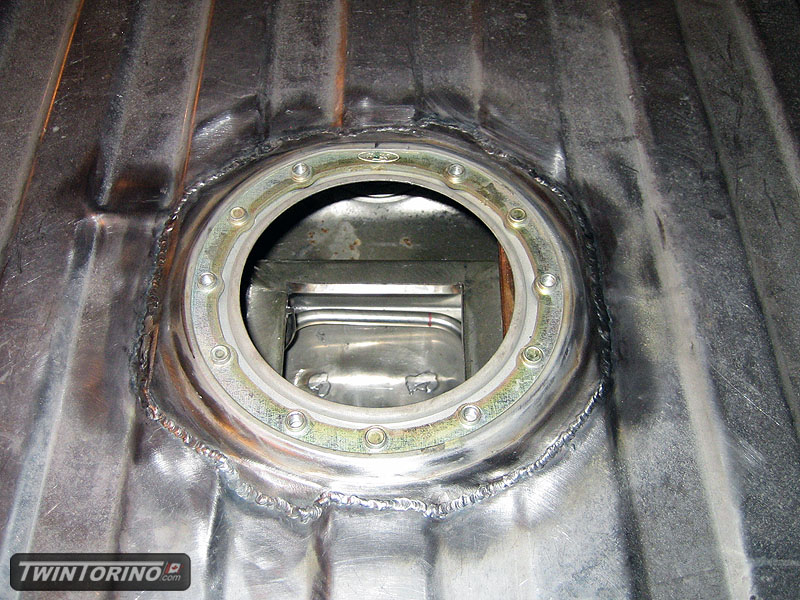

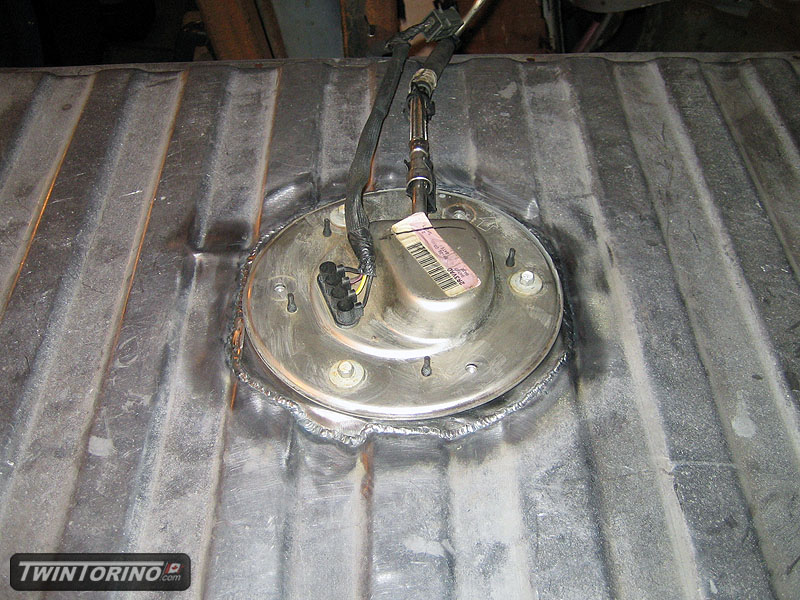

Started cutting up a new gas tank for the car and amazingly the 2004 Cobra fuel pump assmebly is the perfect height for these tanks. Just need to integrate a sump into the tank for the pump to sit in, and then modify the upper flange and weld into the tank. Surprised to see a “Made in Canada” tag on this tank, a pleasant surprise. Very nice quality part. Since the gastank is also the trunk floor in the this car, we will likely just make up a guard to protect the pump housing and lines.

Moving on – need to connect all of the systems together. Picked up some stainless 3/16″, 1/4″ and 3/8″ lines and found the appropriate clips, etc to attach to the car. This stainless tubing is seamless and annealed which makes it much more pleasant to flare. The Mustang has a wonderful mix of flare nuts, M10, M12, 3/8-24 and 7/16-24 to connect to the master cylinder, proportioning valve, ABS controller and all 4 corners. Since this is a 4-channel ABS system we also need to run 2 brake lines to the rear. Also have Goodrich front stainless flex lines and Maximum Motorsports in the rear.

Pullmax..

Moving right along on progress. Back to the engine – we are converting the engine to dual bore throttle body instead of single in attempt to get a bit more power out of it. It is a known issue with the M90 blower kits as the pressure drop across the throttle body is much higher with the single bore. This also means we now need to make up a custom clear air tube, which will either be carbon fiber or aluminum (see below for how).

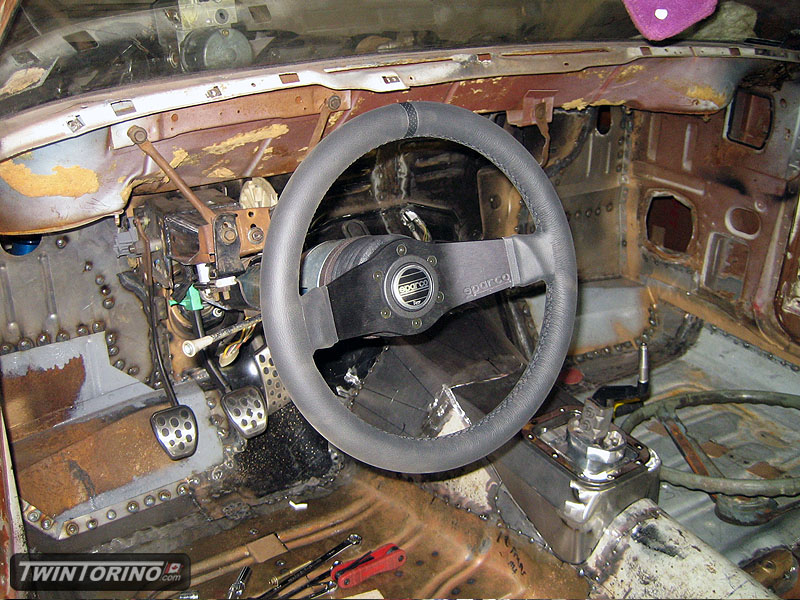

Got the steering column modified, and got a Momo Ford specific adapter for the steering wheel. Adapter/wheel takes some getting used to, but it is growing on me. For those of you running smaller OD steering wheels on these cars.. how the heck do you see the gauges??

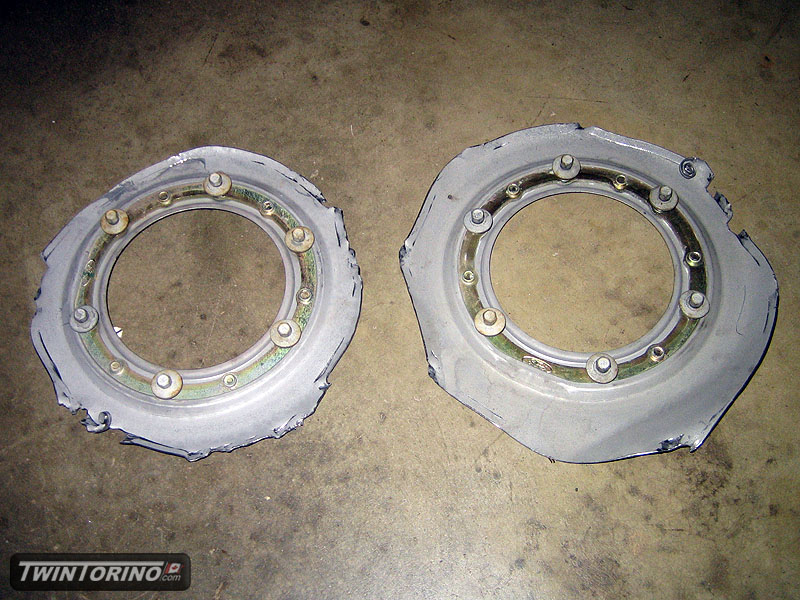

We were not really sure how we were going tin integrate the Ford fuel pump into the tank. Then one day the lightbulb went off and I realised that we should likely get someone to cut the tank flange off at an wrecking yard. Taking that one step further, we called al late model Mustang wrecking yard and they helped us up with

Took a road trip this weekend to grab a new toy that was too good to pass up. It is a Pullmax model D3. We have been looking for years and years for one of these to show up close to home and for the right price. This was only slightly more than the price it would be worth if scrapping it. It works like a charm and we just need to make up some tooling before we can experiment with making parts for the Torino. We even broke out the custom trailer for the event :).

Konis and Fuel..

Scored a pair of used Cobra IRS Konis for car #2. Fresh rebuild on these with zero miles. Came with shock dyno sheets too which was a bonus. With car #1 getting closer to an operational state by the day, we are trying to get everything in hand to be able to dive into the next one.

Moving onto the fuel system – we decided to run a 2003/2004 Cobra fuel pump assembly. This is a unique 2003/2004 only setup that comes with dual pumps to provide additional fuel with the supercharged application. Since they cost a fortune new, we opted to go the used route as usual. We decided to run a returnless system like the stock vehicle. This system uses an FPDM (Fuel Pump Driver Module) to duty cycle the fuel pumps to target a desired fuel pressure which is measured by the computer at the fuel rail. Alternatively, we could have run a return system with a pressure regulator, but we opted to use what came with the Mustang originally.

As for fuel tank – for now we will use a stock 68/69 Torino tank. We will weld in a flange on the top front center area to allow this fuel pump module to bolt right in. We will build a reservoir/baffle setup at the base of the tank similar to what is in a newer Mustang to help prevent fuel starvation. Float rod will be a custom one using a stainless welding rod to take the shape of the Torino tank into consideration.