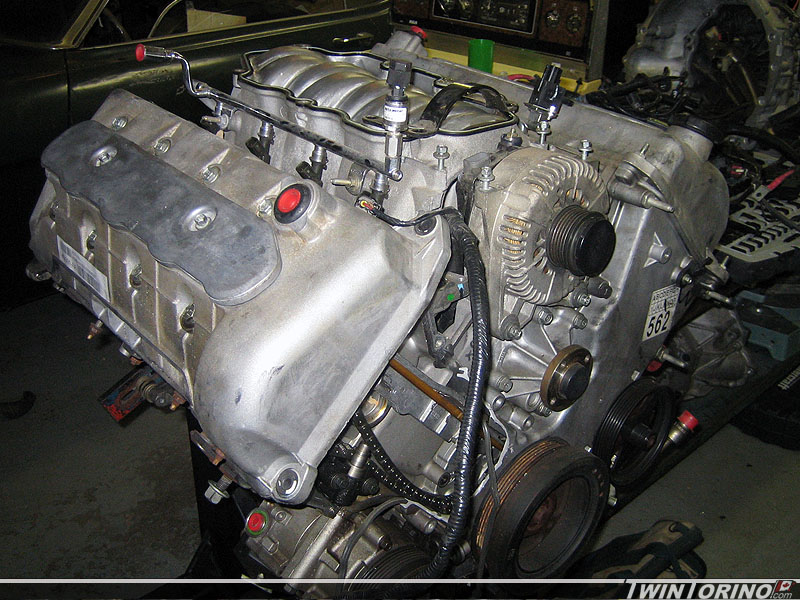

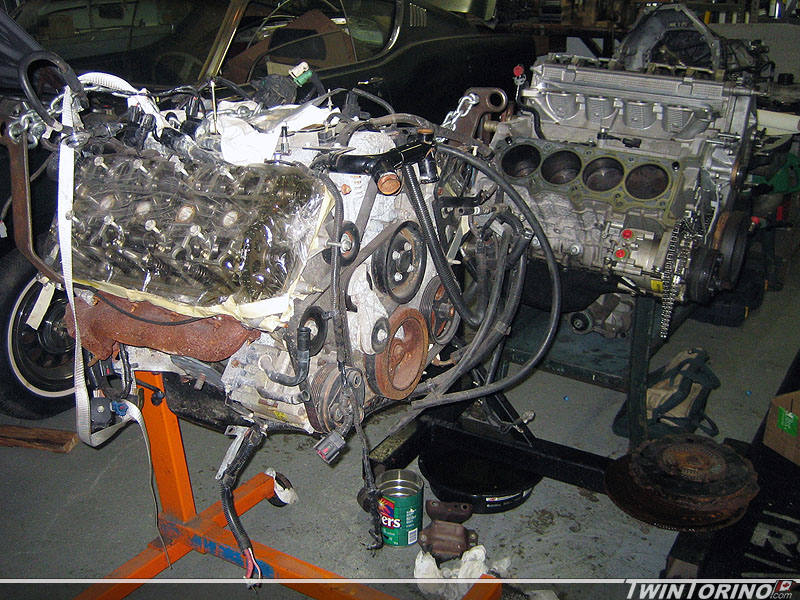

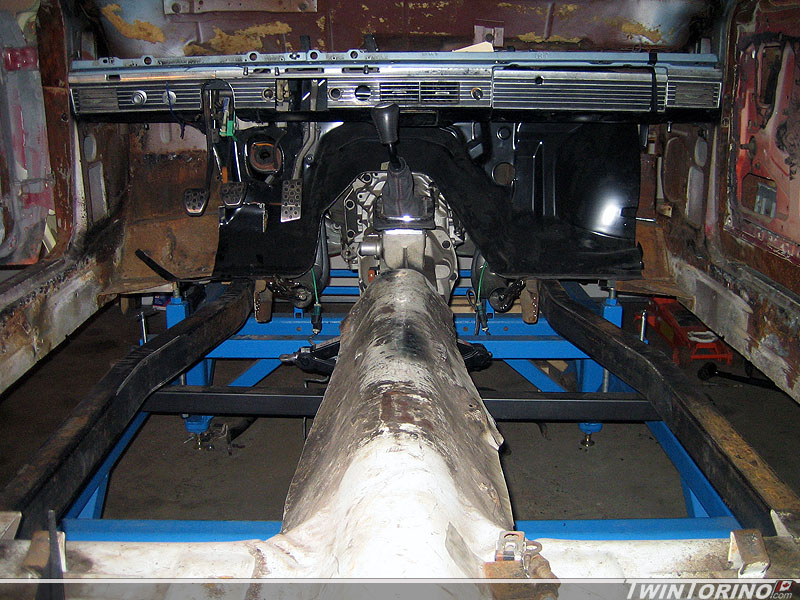

Finally time to start working on the fun part of this project – the powertrain. We have 2 kits to completely rebuild and upgrade the 6-speed transmissions, and the engines will just get a refreshing/upgrade and make sure everything is OK inside. After all, they are only 5 years old.

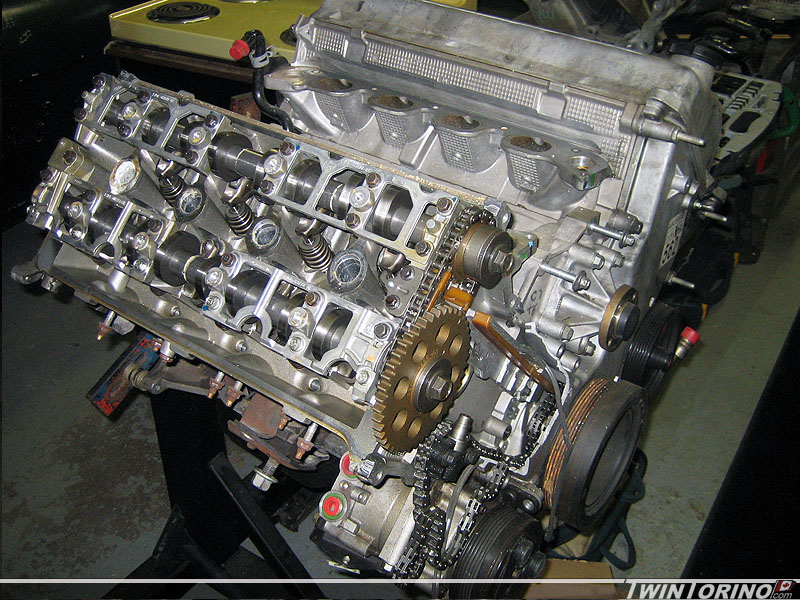

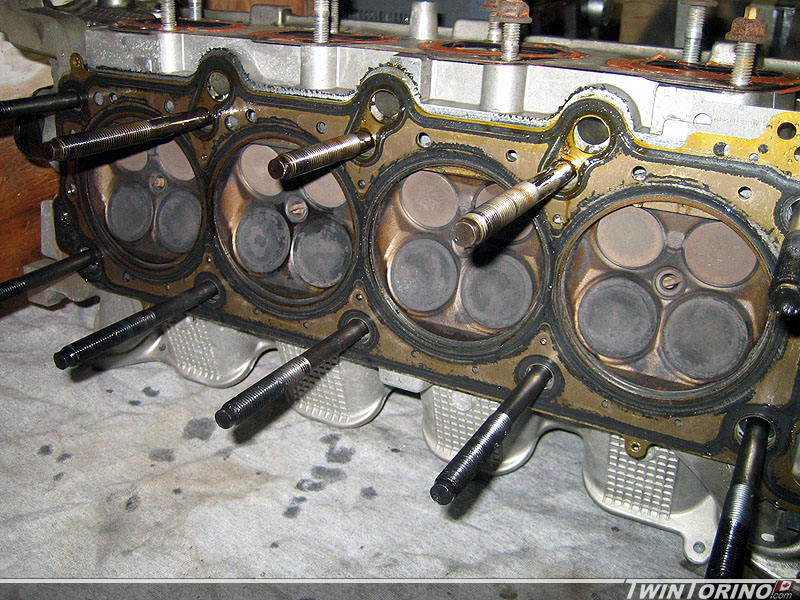

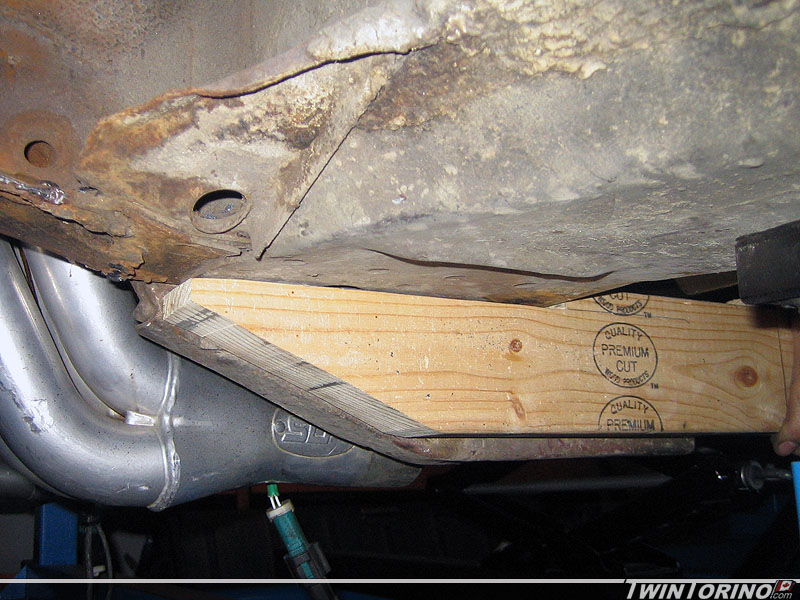

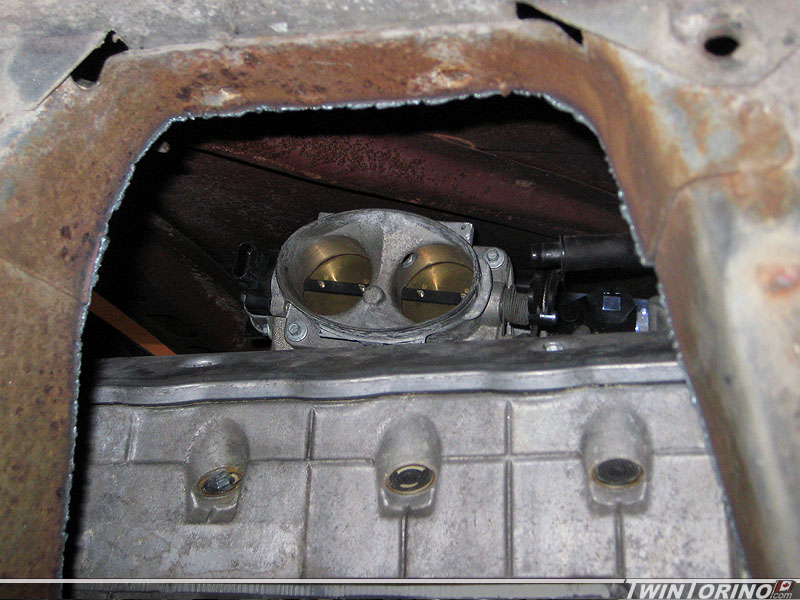

One of the engines we bought came from a car that was a write-off and have some issues with the front cover being cracked as you can see. We took a risk on this (since we only have pics to go by) and hoped that there was no internal damage from the timing chain coming off. Sure enough when we pulled the head off, all was well inside. Gotta love the 4 valve heads :).