Category: Wheels/Tires

Georgia Wheel Time

Thanks guys!! Sure is easier to keep motivated now with a car that actually does something other than just sit there. Can’t wait to bring it out to the bash next year under its own power (assuming there is a bash next year).

Since one car has an end in sight.. time to move onto #2. Got the rims and tires mounted over the weekend. Hoping to get that car up on the chassis jig shortly to start chopping.

Same tires as the other car – Michelin Pilot Sport Ps2 275/35/18 front, 315/30/18 rear. Rims are forged and from a Roush “Blackjack” edition, with one set narroed for the front.

Wheels and Exterior Shots

Finally time for some inspirationsal shots. Got the wheels back yesterday from Weldcraft – they did an excellent job. I measured run-out on the machine and they were near perfect. They also took very little weight to balance.

We mounted up the wheels yesterday and dropped the car on the ground and rolled it outside for the first time in years. Got the ride height pretty close to where it will be – looks pretty mean. Front suspension is riding on the coil-overs, and the rear is just blocked up using wood for now (waiting on springs).

Figued we may as well try throwing one of the engines in to see how everything fits while we are at it. Everything fits surprisingly well. Just need to establish where to drill holes in the relocated motor mounts to get the engine as far back as possible. Big thing is the supercharger clears the hood with lots of room to spare. May not end up running the hood scoop in the to keep the stealth theme going :).

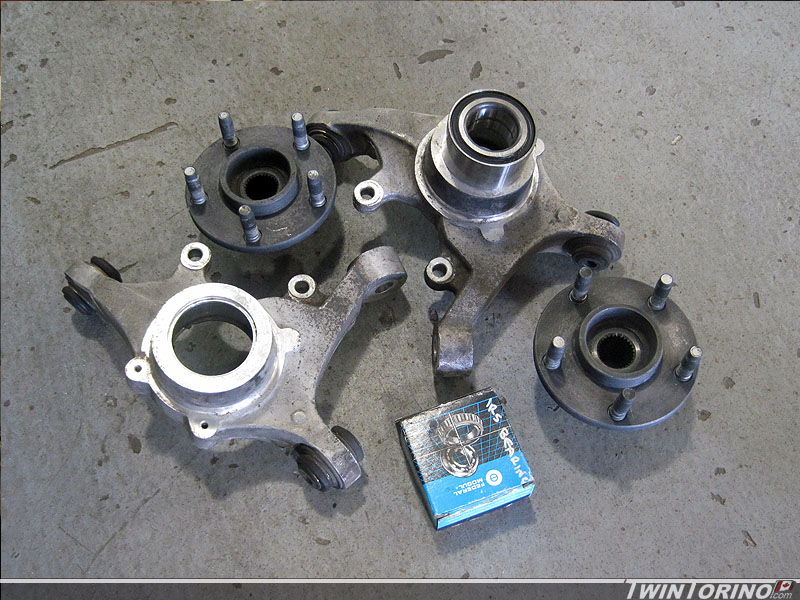

IRS Bearings..

Front wheels went out a week or so ago to Weldcraft Wheels to get narrowed 1″ to 18×9 and we expect one set back this week. After that the car can actually sit on the ground on actual suspension and not have the tires rub on something. Replaced the rear wheel bearings on the IRS as they are a weak point in the design and one was on its way out. They are done and back in the car again now after cleaning them up and pressing in new bearings. Also mocked up the front sway bar and fabricated most of the parts needed for the rear spring perches. Need to grab some more pictures and post them.

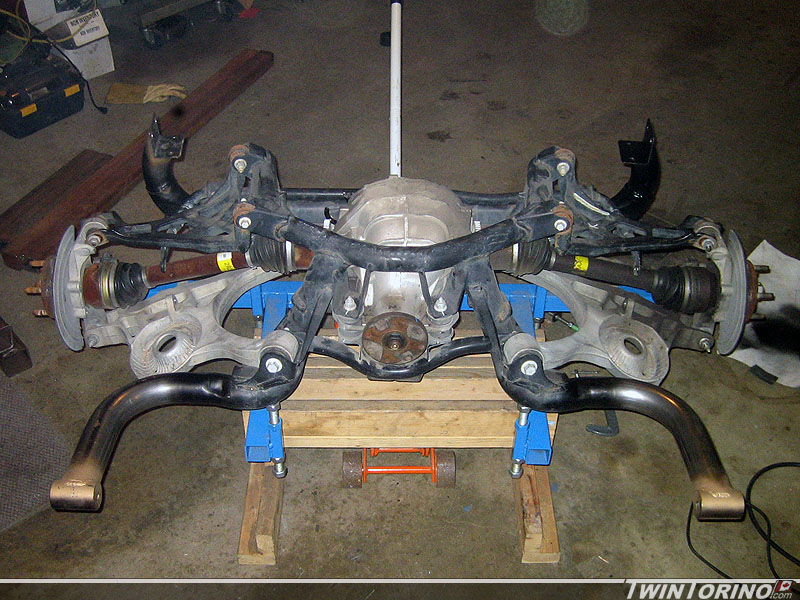

Rear IRS and new wheels..

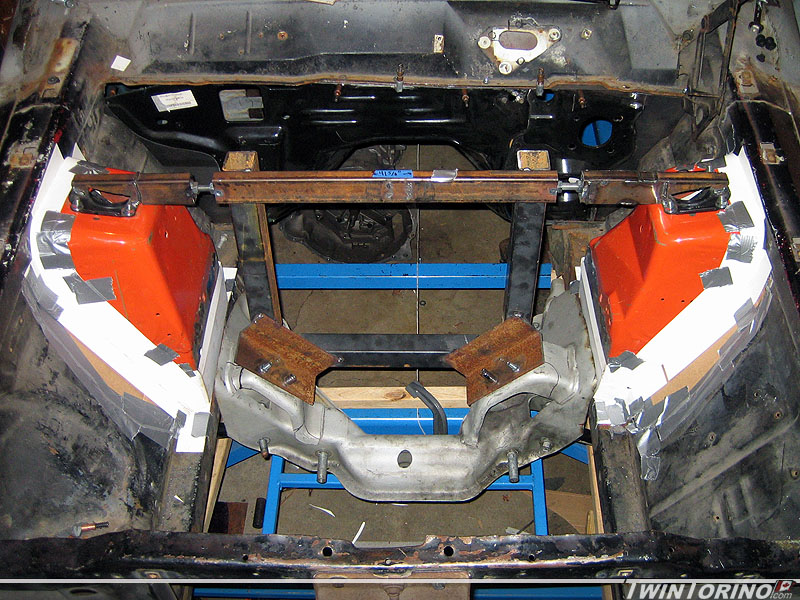

Moving right along.. been a busy week. Our goal was to have the car ready to go on the ground by the end of March. We were working right up until 12:00 and baraly finished most everthing. Just need to finish up the rotisserie and it can go back on the ground for the first time.

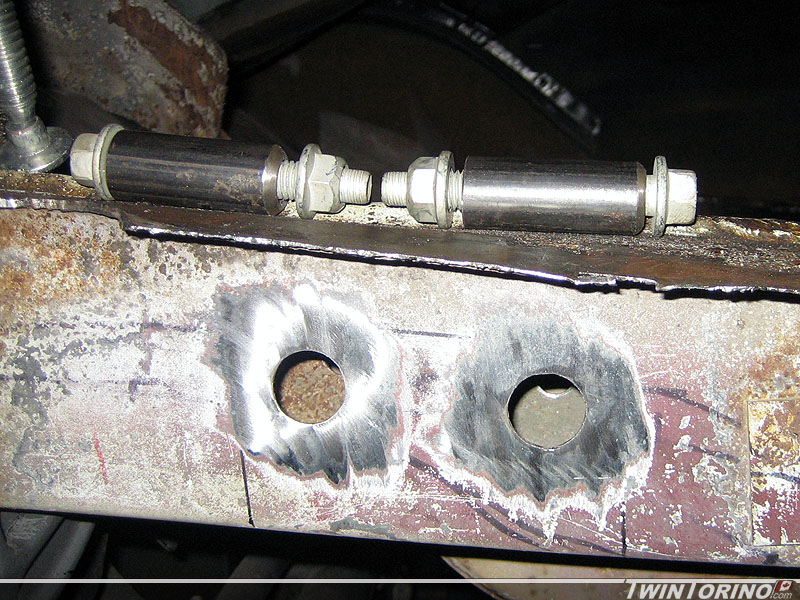

Drilled out the frame for crush tubes and welded those into the frame so the brackets can be safely bolted to the frame structure. Once those were done, it was time to weld the tubes at all 4 corners of the assembly. We pulled the entire IRS out and finished all of the welds up. It kinda looks like the tubes came that way from the factory :).

Also may be changing the wheels up a bit. We got a couple of set of Roush forged 18×10 wheels (scratch and ding models) and decided we may like these better. As luck may have it, the offsets were very close front and rear. Only problem is that an 18×10 won’t like the front clearances, so we are going to have to get the fronts narrowed since there is no such thing as an 18×9 in this model. Not the hugest fan of chrome, but it is growing on me.

Setting Initial Alignment..

Managed to work on the car a bit over Christmas. Hoping to maybe even get the car back down on the ground soon enough. I got a Longacre caster/camber gauge for Christmas this year so it was time to put it to the test. It is a nice billet piece with lots of bubble levels on it. The only unknown parameter in the mix was the caster that needed to be set for the vehicle (as camber is relatively easy to measure with a digital level). Ford recommends 3.6-4.3 deg caster on the Mustang. We are setting it to approx a min of 4.5 and max of whatever the caster/camber plates allow. The larger number will mainly be used on the track. These numbers are generally agreed upon in the Mustang world, and lower recommended numbers are based on the fact that the Mustang was designed with the “average” vehicle owner in mind. The shock towers were simply slid forward until we saw the measurements we wanted. They are now fixed in place.

Also managed to find a barely used pair of 275/35R18 Michelin Pilot PS2 tires to try out on the car (same size/model as a newer Viper so they are not that hard to find). They were mounted up on the car and we ran through a clearance check and they fit perfectly. The hardest part about getting a tire to fit is while turning the tire when the front suspension is compressed, and they also need to clear the coil-over suspension.

Also moving right along on the front strut towers. Have all of the pieces tacked together on the driver’s side and everything fits great. Should be able to weld these in soon. Just need to add a piece in the top corners and they should look factory stamped.

Towers, Slicks and Scales

Got the point where we finalized the front strut mounts and achieved the desired caster and camber targets (took a lot more time than planned to manipulate everything to get it perfect). Now it is time to bridge the gap between the Mustang strut towers and the Torino. Went out and bought half a sheet of 16 gauge steel (same as the Mustang towers) and made up templates using cardboard. Just need to bend these up in steel, cut and weld into position.

Also landed a couple of good deals in the past week or two. Bought a set of tires for the track for $100 – Michelin Pilot Sport Cups. These come new on the Porsche GT3 and the Viper ACR. They are basically street legal slicks. These ones are 265/35 18’s and have lots of life left on them. Also picked up a set of Rebco corner weight scales for setting up and weighing the cars. I bought them as non-functional for only $25. After and hour of troubleshooting and fixing as issue with the circuit board, I had them up and running. I always wanted a set, but could never justify the $1500 cost. Now I can weigh anything and everything on the car, and the car itself. Will be interesting to see the weight difference between the motors etc.