Category: Electrical

Details and Lighting..

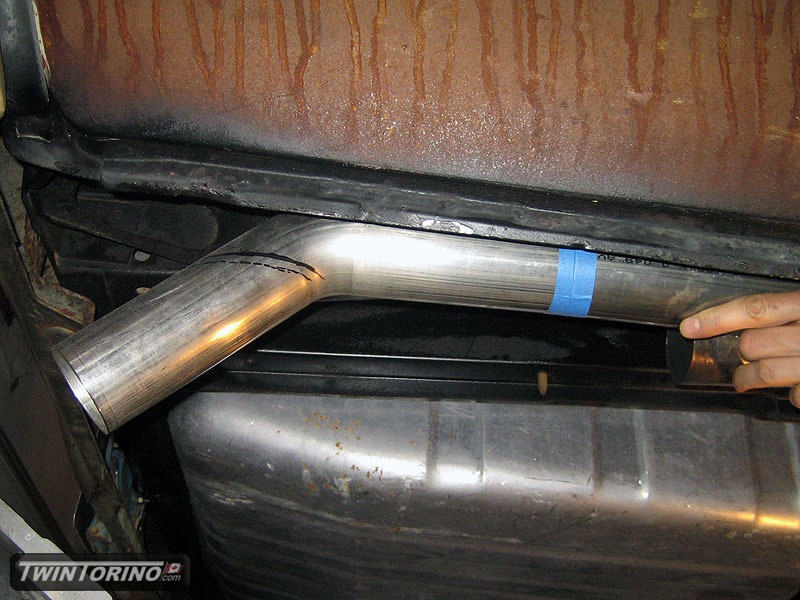

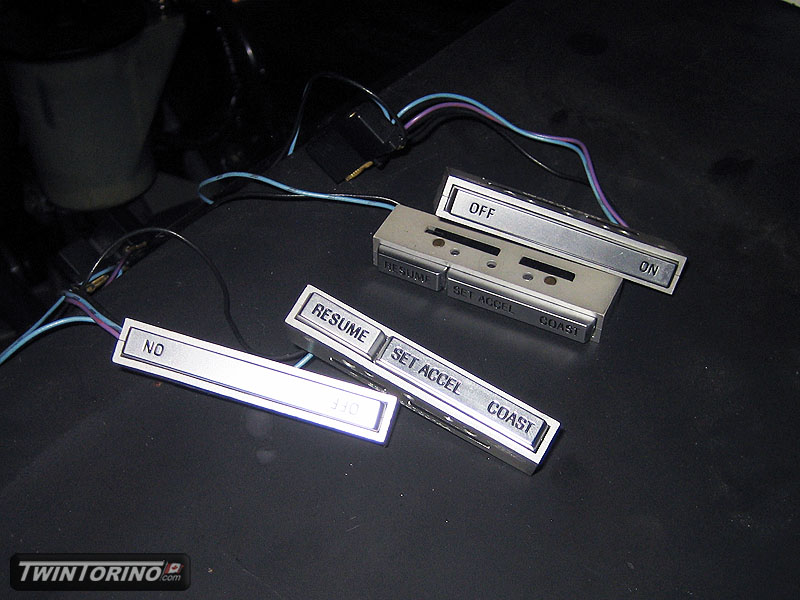

Moving right along.. time for the details now as we are slowly running out of things to do. Time to start making things look good. Have spent a lot of time sandblasting powdercoating brackets etc. Also decided to wrap up exhaust while we were at it. Going with the stealth tips for now and will be cut almost flush with the rear body line when done. Was not sure what to do about the cruise control as most steering wheel buttons don’t look right in an old car. Other issue is having the electronics on the buttons work with the modern electronics. Turns out a mid 80’s Crown Vic fits the bill here. They are metal looking buttons that do not look at all out of place on the Torino. They will likely make their way beneath the dash in custom housings.

Next was lightning. Lots of options here.. most of them are sub par. Seems most lights are looks over function. Several paths we can take here. Go out in left field and make a custom HID setup using the guts of a new Ford HID light (Mustang, Taurus, Explorer etc). That just screams $$ and time. We’ll revisit this later. Note that putting HID bulbs in a standard halogen based housing does not count. HID bulbs require their own custom projectors and provide horrible optics when placed in a non-HID designed housing, and will also blind oncoming traffic with even the low beams on. Not quite sure why this fad has taken off in the aftermarket. There is a reason why cheap HID kits are only $100, and high end ones with the correct housings are 10x as much.

Ok.. back to the point here. Several options for Halogen based lighting. Goal was to run H4 for the outer bulbs and H1 for the inners. Main objective is to have a crisp lighting cut-off and glare free lightning. Basically be able run very bright lights without blinding oncoming traffic but still be able to see everything. Three obvious options in the order of increasing cost: Autopal, Bosch and Cibie. Pricing wise, one Cibie housing costs the same as a set of 4 Autopals. There are mixed reviews out there on the Autopals, plus they are not easily available with convex lenses – only flats here in North America. You can get the H4’s in convex (HL-103-H4), but no H1’s (HL-103-H1). I looked everywhere – only place you can get them is in Australia. Shipping cost rules out that option. Next is Bosch. Not a fan of the look of Bosch housings as they only come in flat lens, and they get mixed reviews. The last selection is Cibie lights. These rise above the rest and then some. They are pretty much the best you can buy as far as optics go. I was not really interested in paying the ridiculous prices they go for over here, so since we needed 8 total lights for both cars, I decided to order direct from the UK. Saved about $30/housing in the end with shipping included. I can’t wait to try these out. If they work as nice as they look, I will be all set. For now I will run the std 60/55W H4’s and 55W H1’s. Both with be Osram Silverstars which are on order from the UK. Note that since Torino parts are scarce, 1969 Mustang headlight kits were used and disassemled as used as donors. Since they rest of the car was built using the best of parts, the optics should be no exception.

Next is the trim. Half the trim on this car is anodized aluminum. It may look nice new, but the years are not kind to this combo. Problem is the aluminum is anodized which means there is really nothing you can do to polish it up when it starts to dull. Solution here is to strip the anodize, re-polish and then re-seal, likely by powdercoating. After looking into this, I decided to give the cheap alternative a try first. This was Greased Lightning which I got from Home Depot for under $10. Did it work – sure did. The easy way to tell is to use std metal polish – if the rag turns black, you are in contact with bare aluminum. More to follow here, as well and getting started on stripping the grille.

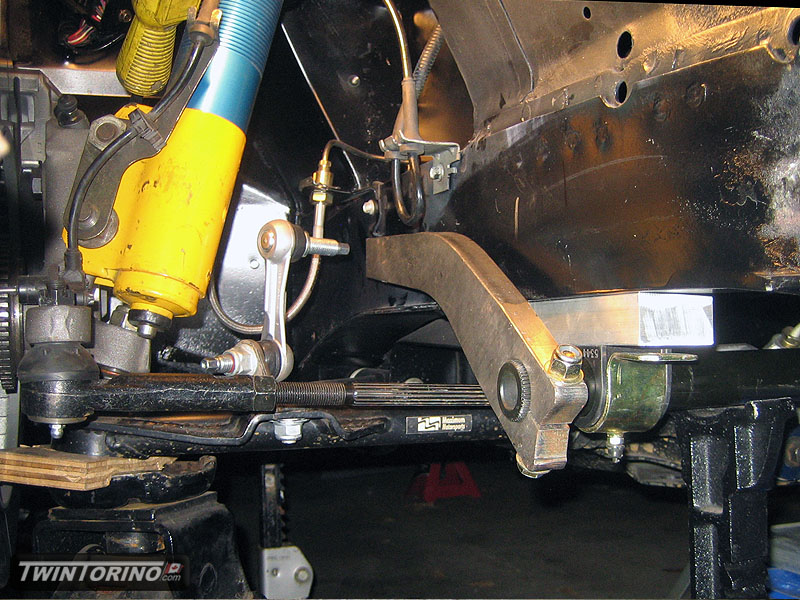

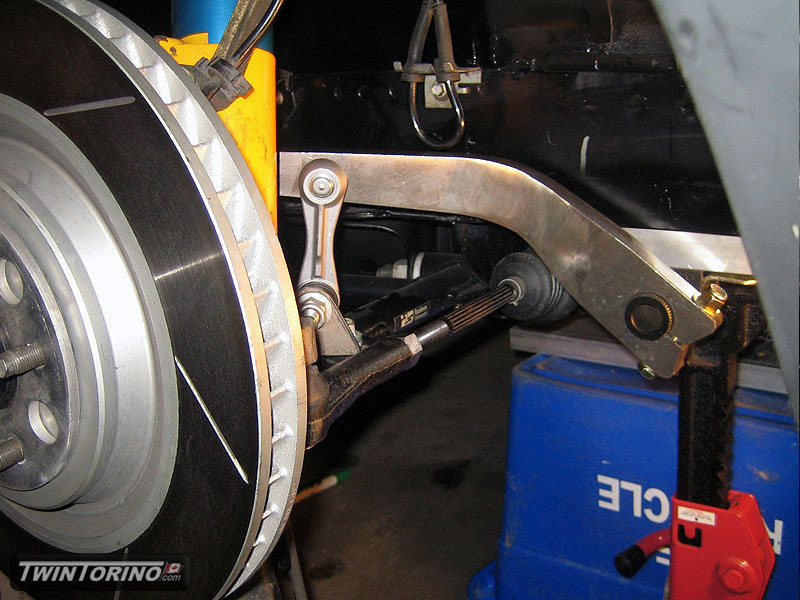

Front Sway Bars

Back to the front suspension once again.. one last item to take care of – the sway bar. Since there is clearly nothing out there that would bolt right up.. we had to modify one to make it work. We are using a Speedway swaybar setup with 30deg steel arms. We have upgraded to using one of our first GM parts on this build. In this case, and aluminum C5/C6 Corvette end link. Since they do not bolt up directly to the control arms (of course not), we had to make up some interface brackets. The arms fit quite well, the only mod we really had to make is bending them 30deg to mate up with the end link. To clear the 275 tires up front, we had to notch the frame to be able to go full lock. After some cutting, v-notching, bending and welding, they kinda look like they came like that.

Also got in some LED’s for cluster backlighting. Will be interesting to see how they illunimate things.

Instrument Cluster – How to Make it Work

OK – this all sounds great in theory.. but how do we make it work?

Largest challenges include:

– Making up transparent faces with LED backlighting.. and on a budget

– Reversing the direction of the gas gauge and oil pressure gauge on the cluster so they follow a logic direction of rotation

– Packaging everything together

– Remotely connecting gauges and odometer to circuit board. This has to be done since the gauge spacing is different.

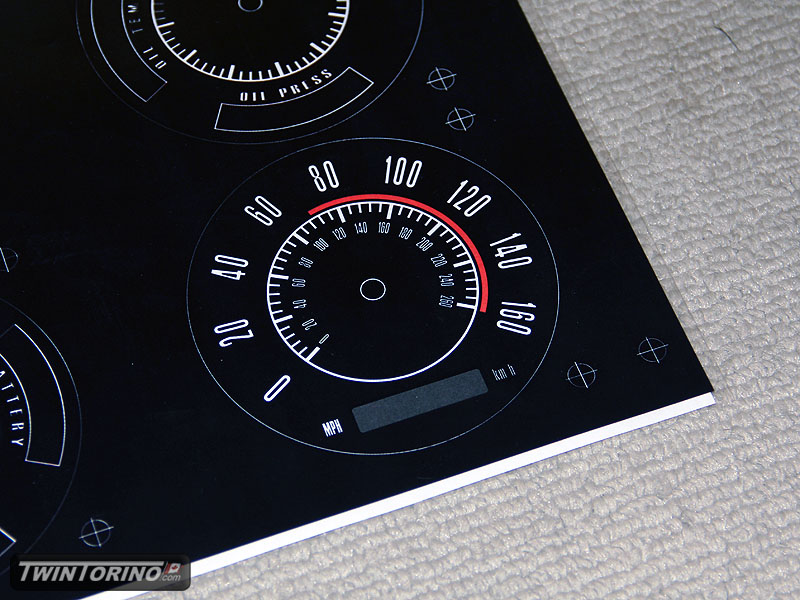

First task is working with gauge faces. After doing some extensive research on the web.. we came up with this solution. Since everything is done in Illustrator, it exists as a vector graphic. In a nutshell this means that you can increase the size of the images as large as you want an they will not distort (unlike normal rasterized images). In theory I could print this out large enough to put on the side of a building if I really wanted to  ). This provides for some very sharp images which is necessary for print out things like the text and tick marks.

). This provides for some very sharp images which is necessary for print out things like the text and tick marks.

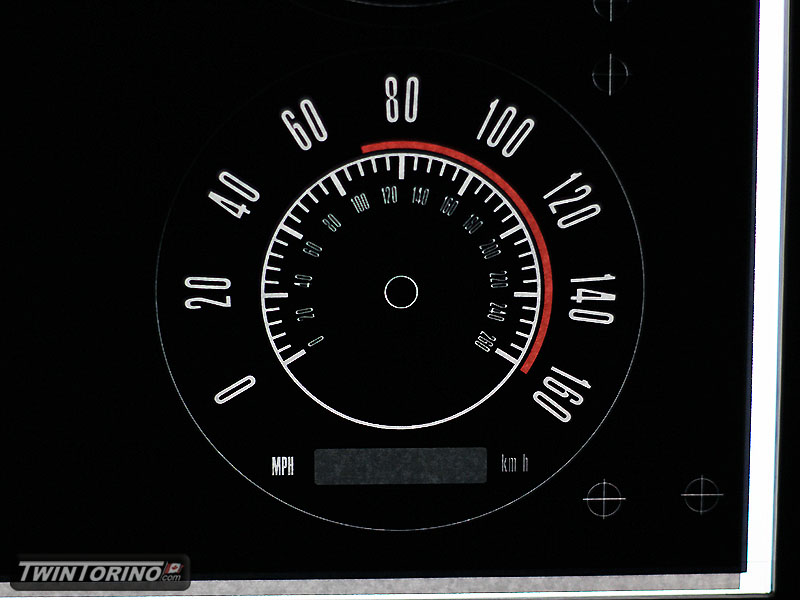

By making up a set of layered images with a high res laser jet printer, we can get the transparent/opague effect. Top layer is a standard transparency sheet printed on the backside (image reversed). The bottom layer is a standard 20lb piece of white paper. Both of these sheets are bonded together to make one piece. Since I did not have the photo mount spray adhesive at the time of making these pictures up, you will have to use your imagination of what things will look like when they are perfectly aligned.

The final picture shows using an LCD computer monitor at night for backlighting. Little to no light passes through the black sections. Looks very similar to a modern cluster. This was relatively easy for the effect it gives. Ideally, we would silkscreen the parts on appropriate materials like auto manufacturers would.. but this will have to do for now until we lock in the design. For under $10, it sure does the trick.

For adding the check engine, ABS lights etc, we will simply add another transparency sheet and omit these images from the front layer. This way you will not be able to see them unless they are illuminated.

More to come as we progress.

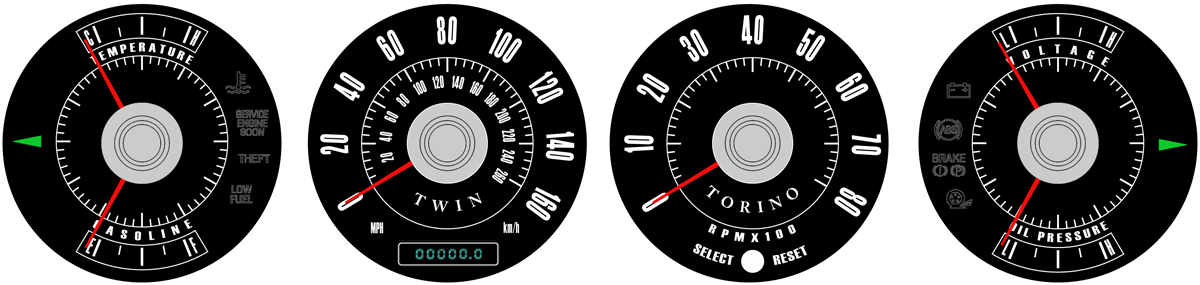

Instrument Cluster Preview

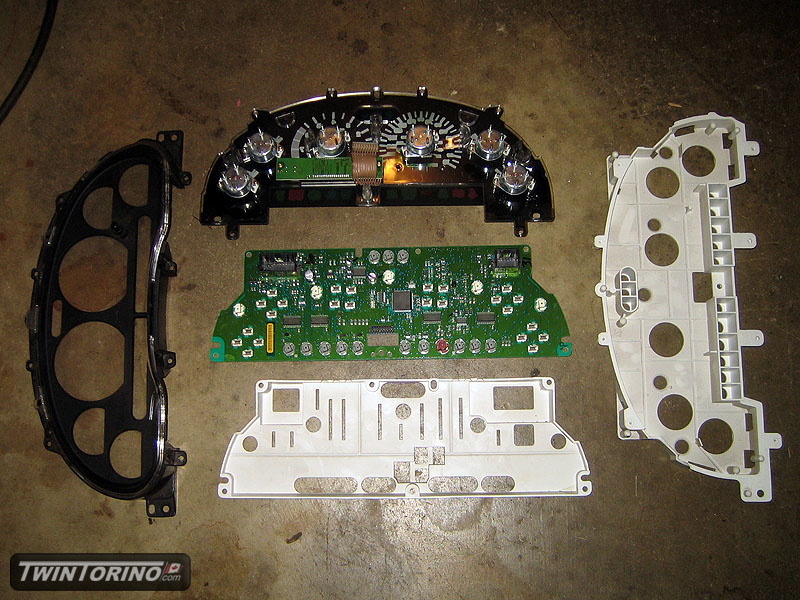

Since winter is basically here.. time to move back into the interior and work on all of the electrical items that have been neglected. For the past while, we have been driving around with a new Mustang cluster buried behind the original dash. If the spacing between gauges were similar this would be OK for now, but they are far off which make seeing anything next to impossible. That brings back the dash design we started years ago.

Several goals with this design:

– Maintain overall original 1968 looking gauges – this was a one year only color

– Backlight with LED’s instead of the original front lighting (requires transparent faces)

– Integrate Mustang air core gauges into cluster so they can be hooked up to the Mustang cluster electronincs

– Use newer style Mustang digital odometer

– Add more real gauges instead of idiot lights

– Integrate all of the Mustang dash lights like ABS, check engine, traction control etc..

– House everything in a modified original Torino gauge cluster housing

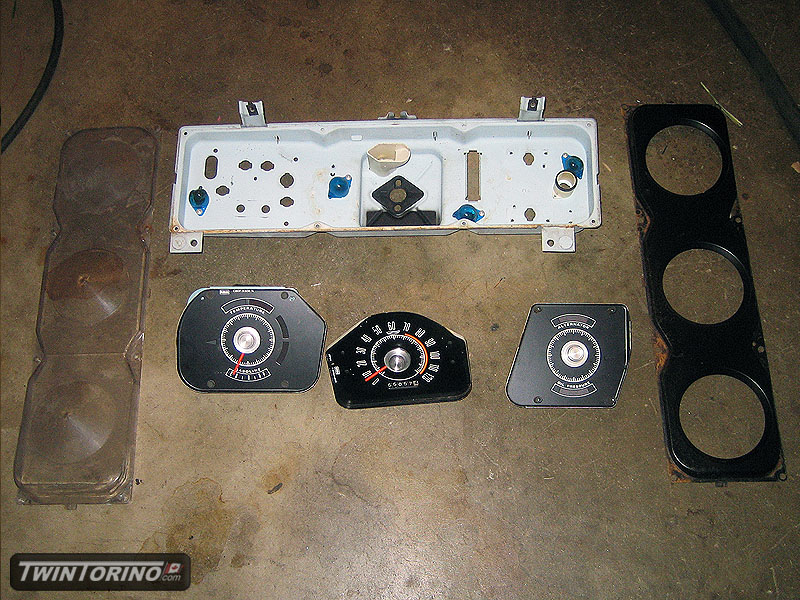

First a look at the oringal parts and pieces. Here are the references – an original 1968 cluster with the tach option, and the “donor” 2003/2004 Cobra cluster with a boost gauge. After that, some spare clusters we have for mock-up – a Mustang GT gauge cluster and a base 1968 Torino cluster.

After countless hours of work using Adobe Illustrator, the first image is what we came up with in the beginning. After some more time and taking into consideration of how the Mustang gauges are set up and how they work, we came up with the last one which we will run with for the time being. The hardest part here was accomadating the Mustang smaller gauges into the package. The lower design also matches the dimensions of the original cluster exactly.

Life After Burning Out..

Been a while since I have updated things here. We took a break for a while on the cars after burning ourselves out in August.

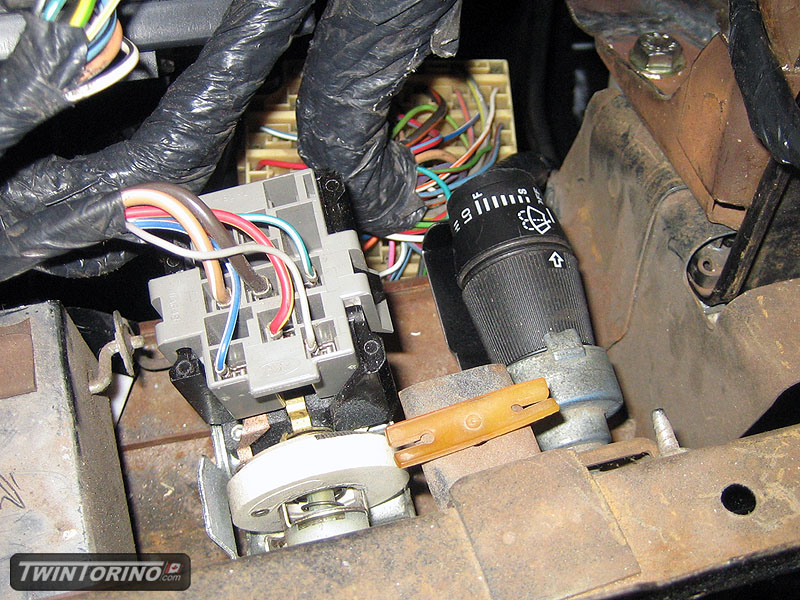

Now started to move on to take cars of the smaller things like interior, wiring, cooling system etc. Got in intemittent wipers to work using the original Mustang multifunction switch on the column. It was unfortunately not as simple as just getting an 80’s intermittent switch like some do because of the way the computer controls them.

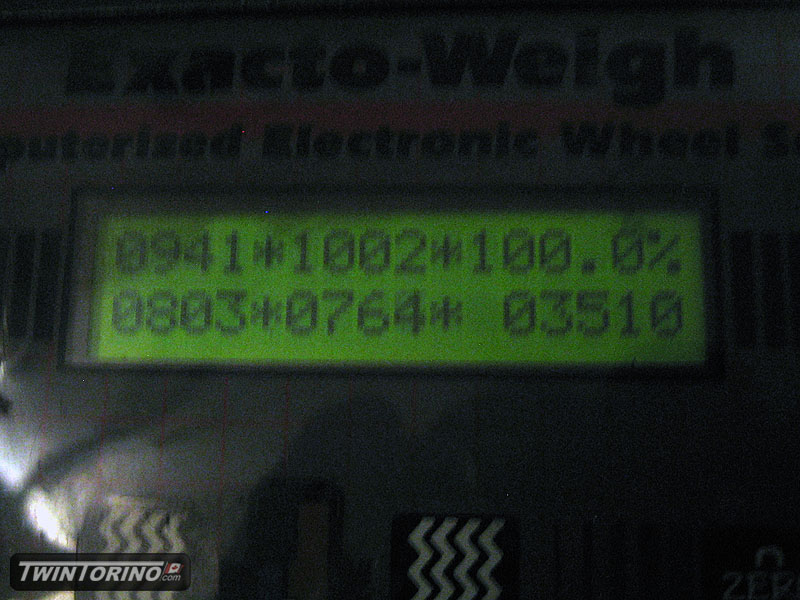

Put the car on the scales now that it is basically complete. 3500lb and ~55%/45% weight distribution. Definitely not as heavy as most would have expected. This was the original goal, we were just not sure if we could get there when adding heavy thing like IRS etc. Still more parts to go on the car – so we approximated them with weight on the car. Once we get into things like carbon fiber bumpers etc, hopefully this will go down.

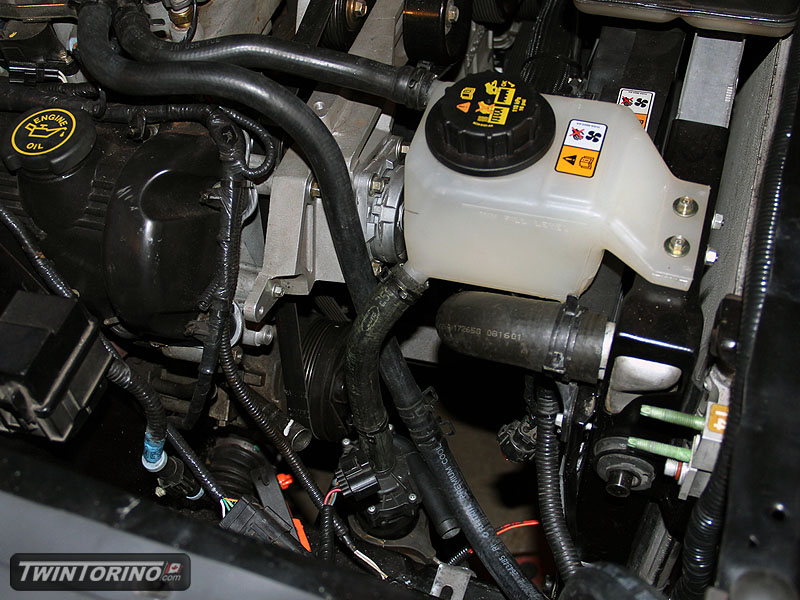

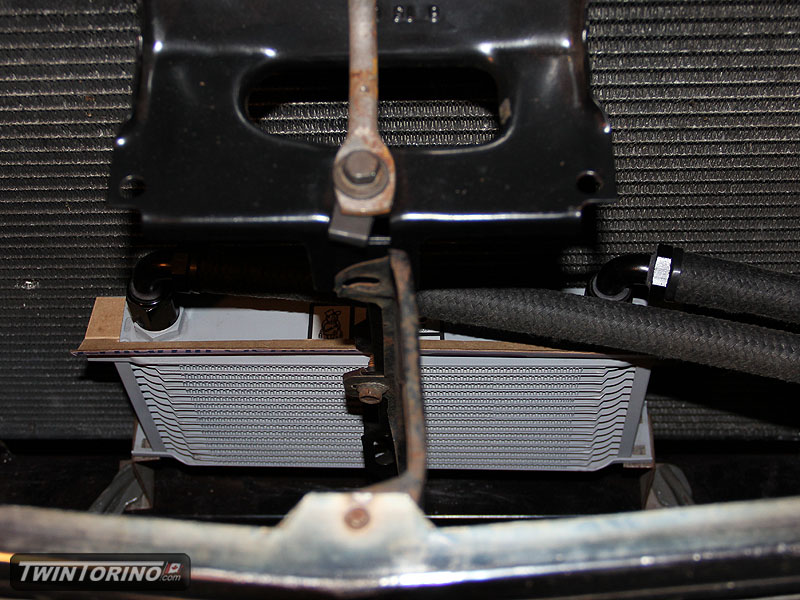

We have been running the past month or two without a low temp radiator loop on the intercooler circuit, so we have not really been pushing the car until we get this in place. We ended up using a 2007 Shelby intercooler pump bracket and sticking it in the sheetmatal brake to make it conform to the Torino frame. Then it was a matter of playing connect the dots with hoses. Still working on the radiator itself which will go behind the bumper. Also have the oil cooler going in.

Still need to get some videos up. I’ll hopefully get those in the next day or so (low res ones at least.. 1080p ones are huge!).

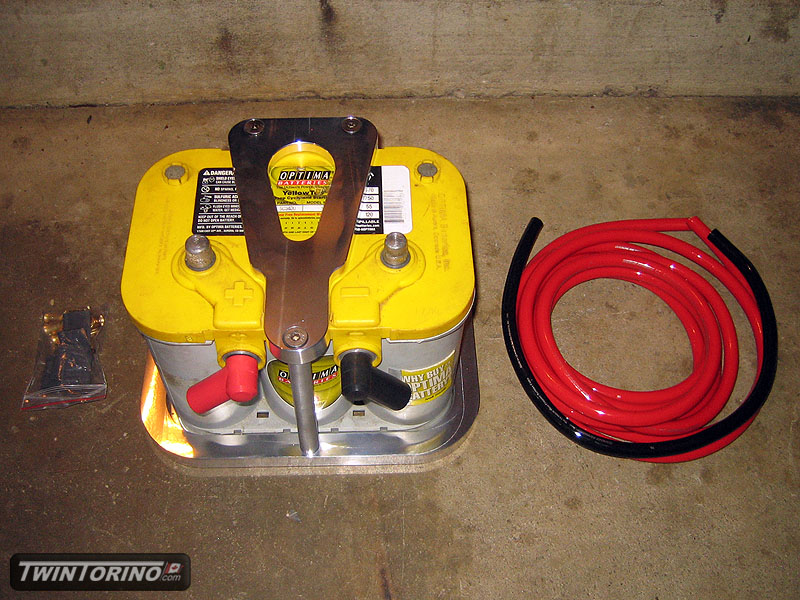

Remote Battery Mount and Floors..

Since we plan on having the car up and running in the next month.. time to take care of the smaller things. Worked on getting the parts together for the remote battery setup. We were going to make our own battery mount, but for the time it takes, we decided to just go with a DSE mount for a 34/78 Optima. To connect the dots, we are using 2 gauge Quickcar cable and side mount location on the battery.

Driver’s side floors have been welded and smoothed out. Pass side is close behind and just need to be ground down smooth. Sure is nice to be able to do this with the car sideways on the rotisserie. Nearly done everything under the car now. Also in the process of of putting the rear seat support back in. It is hard to see in the picture, but we added a recessed area in the seat supports right beside the frame connectors where the brake/fuel lines will clip into on each side.

K-Member Engine Mounts and Wiring

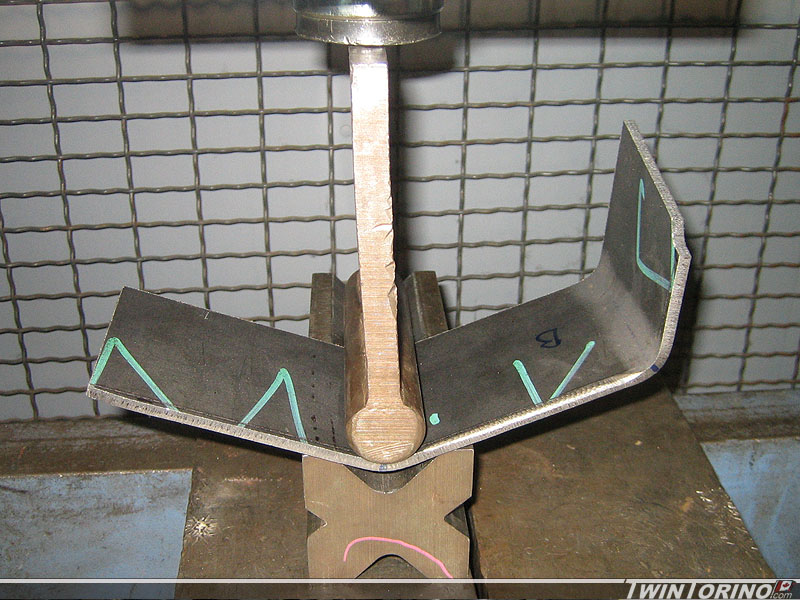

Moving right along – have the Mustang K-member mounting tabs completed. Only thing left to do it shift the engine mounts back 3″ to get the engine as far back as possible. Since the steel on the stock mounts is 3/16″ thick, this means the std brake won’t cut it. Have to move the the hydraulic press for these bends. Got them ready to weld in over the weekend. Will get them welded in this week and then it is finally time to weld the front suspension permanently into the car.

Also found a complete vehicle wiring harness set from a Mustang GT and heater box / ducting parts.

Power Door Locks – Why Not?

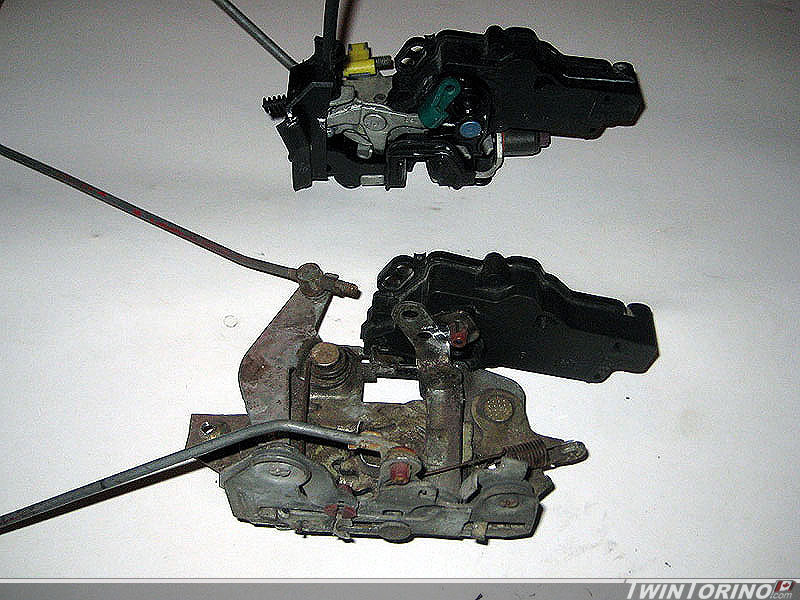

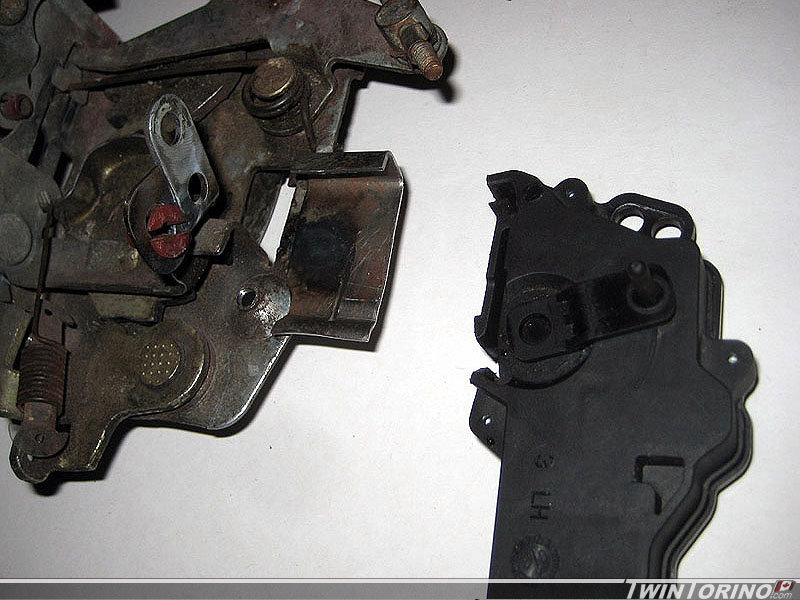

Wanted to change things up this evening and decided to do something other than suspension and floors. Time to add some lazy man options to the car, in this case power door locks. Since the rest if the car is based of a 2004 Mustang, it only makes sense to use parts we already had from our wrecked cars.

We removed the solenoid that comes on the door latch of a Mustang as you can see below, and bent up some steel brackets to attach them in a way similar to the Mustang (with retention tabs and everything). Also had to make up a tab to weld onto the door lock lever that the solenoid actuates and modified it to move with the geometry of the stock Torino door latch. Was even able to work one of the factory Torino plastic bushings into the mix to keep the steel from cutting the plastic solenoid lever. Plugged it into the Mustang door harness, plugged it in and it works perfect. Everything fits nicely into the door. Just need to final weld everything, paint it up, grease it up and put it back in the car for good. Could just have easily bought an aftermarket solenoid kit.. but we got the parts basically free with the parts car Mustang. With this you just push the button on a stock Ford remote and the doors will open.

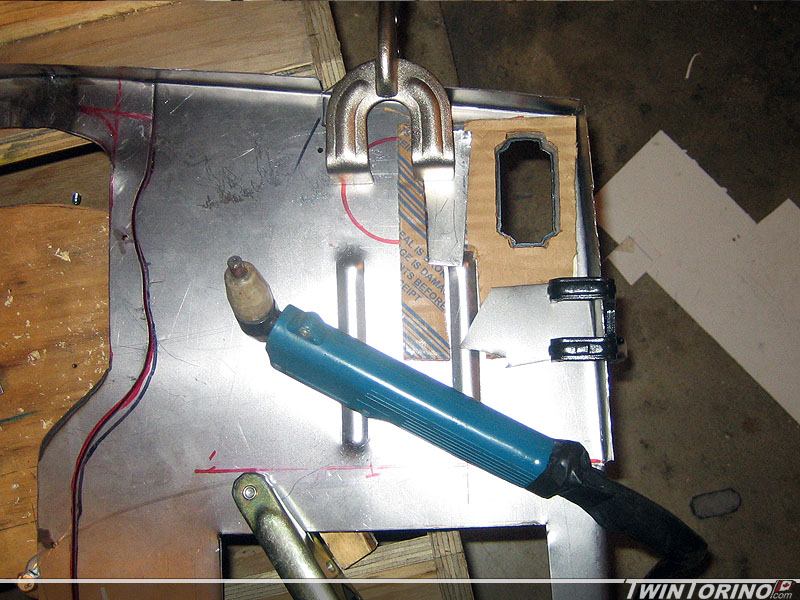

Wiring Pass Through Cutouts..

Couple more updates. Almost have the firewall ready to go in. Worked on getting the wiring pass throughs sorted out and the drivers side piece is now ready to weld to the center portion. Made up some simple carbboard templates to cut out the holes for the Mustang wiring harnesses. Worked great and was very fast. Note sure what I would have done otherwise. Rolled a couple of beads on the part and also step flanged the ends so everything will look flush from underhood after it is welded.

Dash Electrical and Door Locks..

Still progressing on fabricating the firewall up.. just not much to show really until it is ready to tack in.

We started to lay out all of the wiring in the car as that stage is quickly appreaching. There is a lot more room to put everything in here compared to the original Mustang that it came off of. The big challenge here is going to be making room for everything once the HVAC is installed and in position. The computer processor, fuse panels, and lots of other items that wer never on the original Torino need to find home too. The Mach 1 cluster and all the wiring connectors will stay until the car is started for the first time.. and then everything will go on a diet. Al the wiring and connectors that are not needed will be cut out. The parts that remain as original Torino parts (very few pieces like the steering column and various lights) will be spliced in also.

Got started on some of the smaller details of the project. In this case, the door locks. Every once and a while you are really surprised that something works for a change. In this case it was with the door locks. Believe it or not, a lock cylinder from a 2003 Mustang actually fits exactly into the stamped hole in the body of a 1968 Torino. It fits exactly with no mofifications – retainer clip and all. A custom rod is needed to connect it to the door latch – but that is to be expected. I ended up making a quick one with a welding rod, and the key now locks and unlocks the door.. kinda neat. Note that the lock is actually black – for some reason 2004 Mustangs are polished as we found out. Black will eventually be removed. Only one issue here – Mustangs do not have a lock cylinder on the pass side, and Torinos do. As luck would have it – a local Ford dealer was selling off excess stock this week on Ebay, and one of the parts they had was replacement Mustang lock sets. These come with 5 bags of key tumblers, and you simply select the tumblers to match the key you have, and then you assemble and install. This adds a cylinder to the pass side with ease.