Category: Steering

Underbody Cleanup and Part Detailing

In the midst of all of this, it was time to seal things up for the time being, and start to make everything look presentable. This included painting the underbody and engine compartment and powedercoating all kinds of parts and pieces on the car. Everything will be sealed up for good later when the car gets snadblasted. Nothing high budget, just some rattle cans and an Eastwood powdercoating kit.

Pullmax..

Moving right along on progress. Back to the engine – we are converting the engine to dual bore throttle body instead of single in attempt to get a bit more power out of it. It is a known issue with the M90 blower kits as the pressure drop across the throttle body is much higher with the single bore. This also means we now need to make up a custom clear air tube, which will either be carbon fiber or aluminum (see below for how).

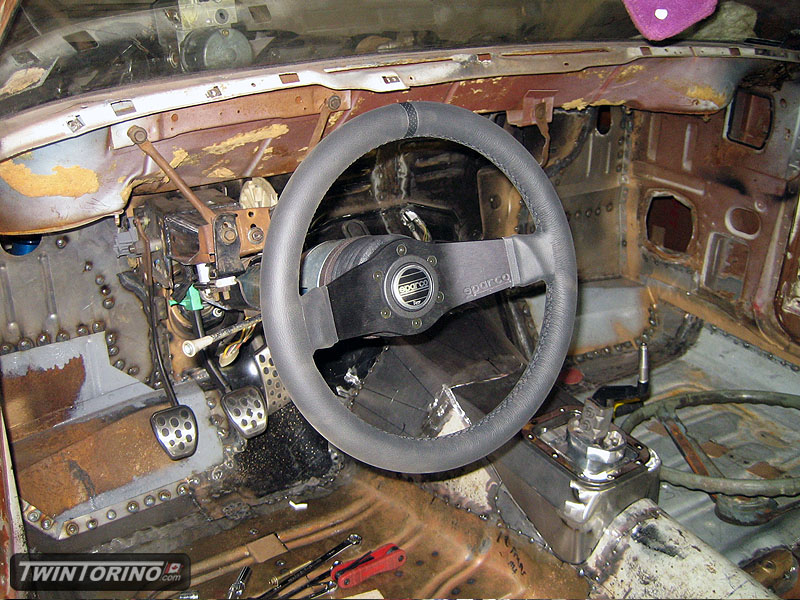

Got the steering column modified, and got a Momo Ford specific adapter for the steering wheel. Adapter/wheel takes some getting used to, but it is growing on me. For those of you running smaller OD steering wheels on these cars.. how the heck do you see the gauges??

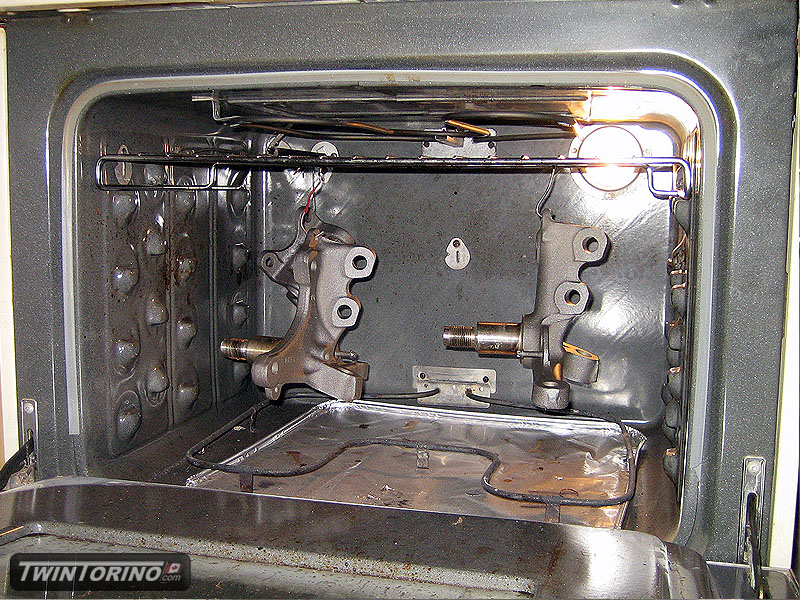

We were not really sure how we were going tin integrate the Ford fuel pump into the tank. Then one day the lightbulb went off and I realised that we should likely get someone to cut the tank flange off at an wrecking yard. Taking that one step further, we called al late model Mustang wrecking yard and they helped us up with

Took a road trip this weekend to grab a new toy that was too good to pass up. It is a Pullmax model D3. We have been looking for years and years for one of these to show up close to home and for the right price. This was only slightly more than the price it would be worth if scrapping it. It works like a charm and we just need to make up some tooling before we can experiment with making parts for the Torino. We even broke out the custom trailer for the event :).

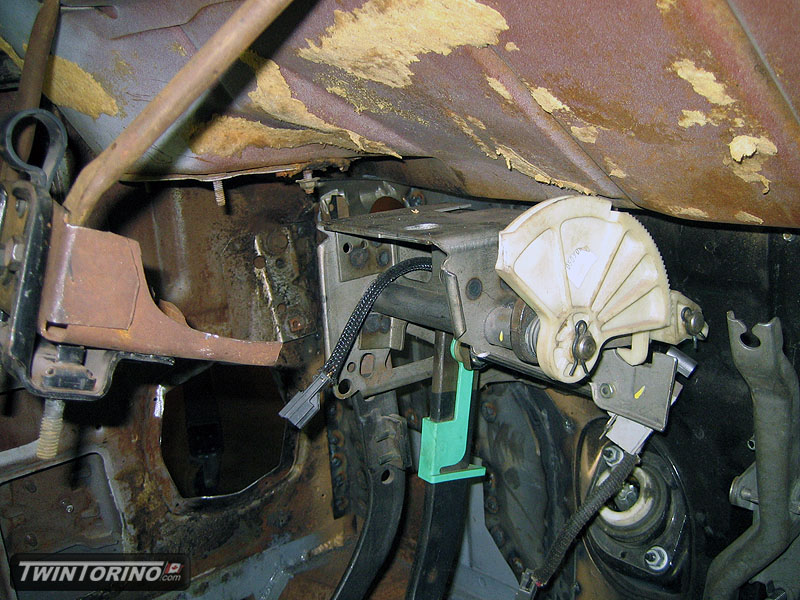

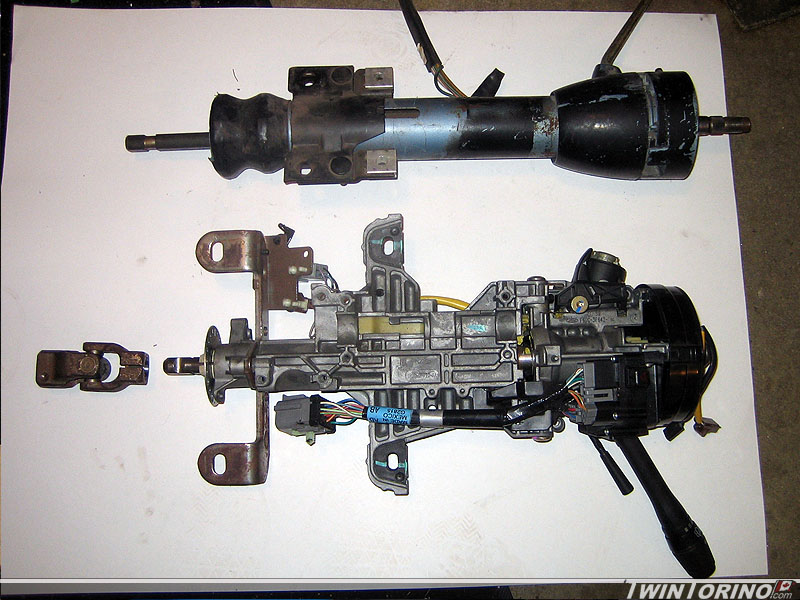

Steering shaft..

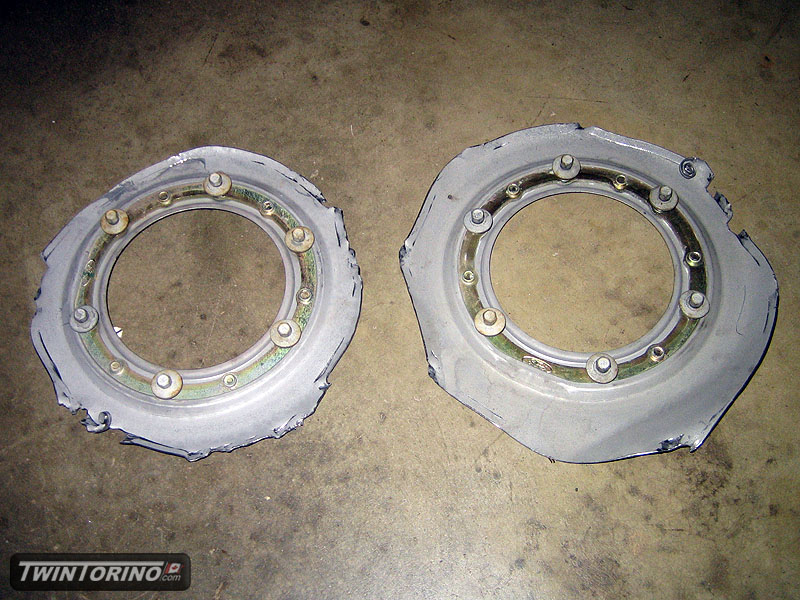

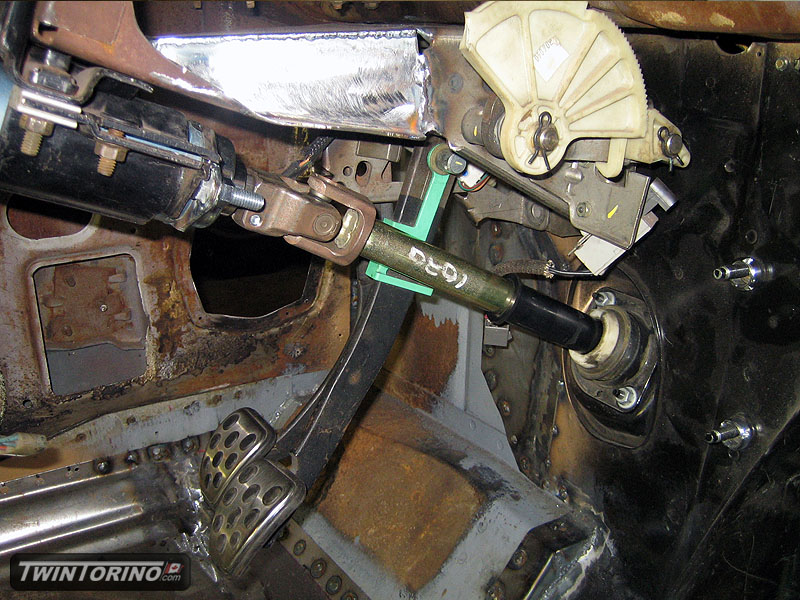

Some more progress over the weekend – since we were happy with the steering and how it worked out, we modified a pair of floor shift columns. The other one we used was an old beat-up column shift one. Just need to powdercoat these when we get closer to final assembly time.

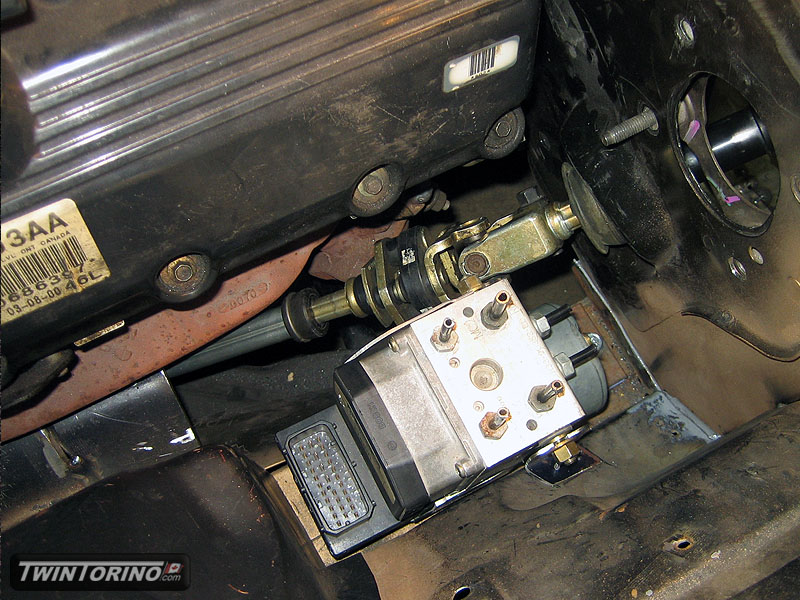

Also moved onto the braking system, and got the ABS module mounted in the car. We opted to move this from the passenger’s side in front of the engine (on the base Mustang) and move it to under the master. This makes brake line routing much more simple, and hides the module out of the way. Thankfully the original Torino steering box sat where it did, as it made a nice place for the module. Just need to run the lines now. Will be starting into the fuel system next week – getting closer to a running and driving car by the day.

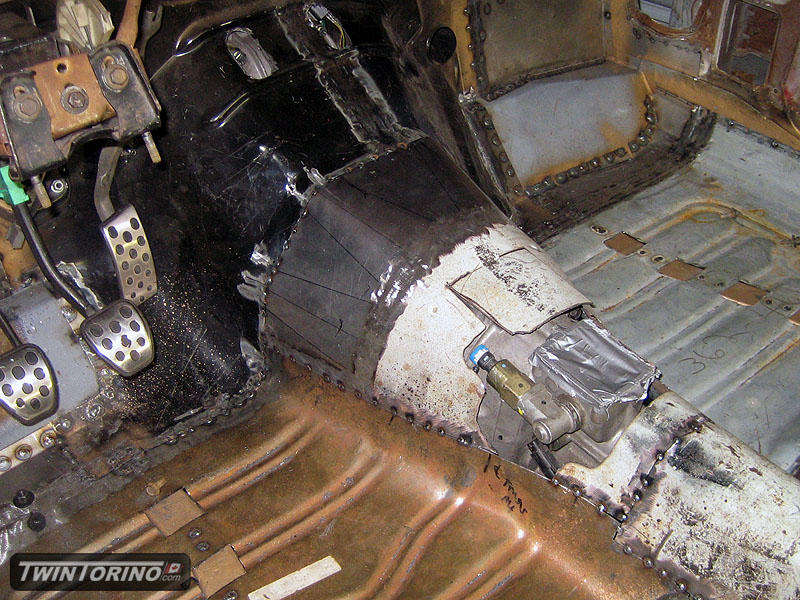

Trans hump and steering..

Finally.. lots of free time to work away at things. Made up a shifter hump to conform to the carpet and clear the reverse lock-out solenoid on the transmission. Almost ready to cut the floor away and weld in. After that, floor fab is done and only needs to be final welded.

Found someone on Ebay selling oil thermostats cheap on Ebay so I grabbed a pair of them. These models are actually for a Lotus, but work fine with the Torino since it is set up for an oil filter with a 3/4-16 thread. You simply remove the oil filter and stack this on top and put the oil filter back on. Since we are running an external oil cooler, this is a must in order to let the oil in the engine get up to the proper temperature (same as a thermostat in the cooling system).

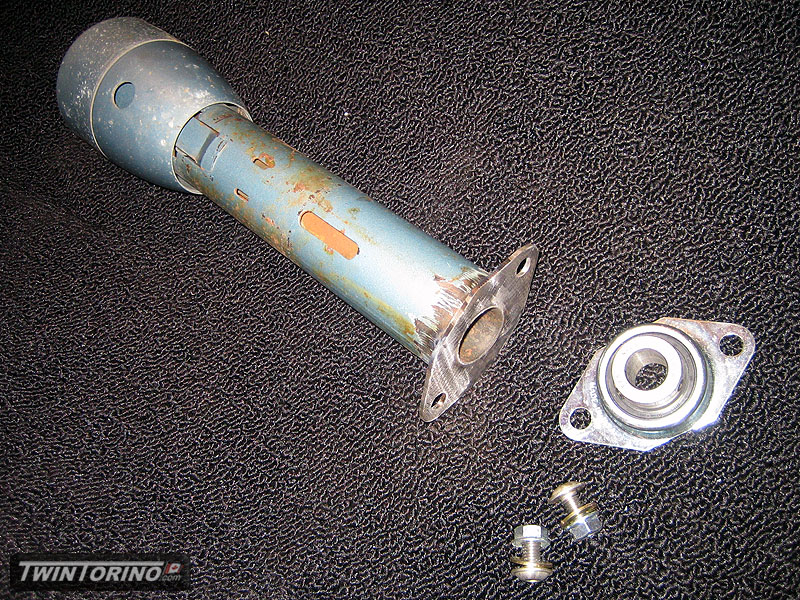

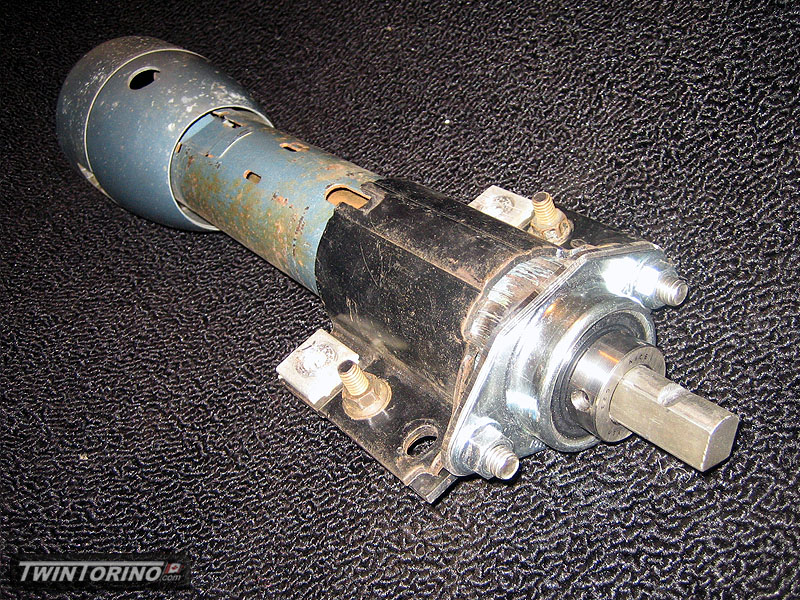

Moving onto the steering system, we found the necessary parts to make it work. The “trial” steering column was cut down considerably and a bracket was welded onto the end to accept a flange bearing. The inner shaft is then cut down to mate with the intermediate steering shaft. This shaft then connects to the lower shaft, which then connects to the rack. The steering colum has to be cut back so far to clear the brake pedal. This also reduces all of the u-joint angles. Believe it or not, these shafts are from a 2004 Lincoln Navigator ($20 on Ebay). The connection on the steering rack is a custom Ford only one, so this limited the choices to a Ford vehicle. Alternatively companies like Borgeson make the parts needed to put together all the shafts, but they are not cheap. Mustang ones will not work since the suspension is further forward. The firewall bearing is from a Mustang. For the first time in years – the Torino can once again be steered using the steering wheel.

Pedal Support..

While everyone else was watching football, we were hanging out in the garage. Got the trans tunnel tacked in – once the carpet comes this week – we will finalize the hump and weld it in. This was by far the most annoying piece to make fit since it was constrained tightly on all sides. In the end it fit up nicely to the Mustang firewall and stock Torino floorpans. Just need to final weld everything and the floors will be all set.

Also started to get the pedals and the steering under control. We ended up taking an auto pedal assembly and cutting most of it away (except for the part that bolts to the steering column, and bridged the gap between the two. Once we are finished welding this up – it will hopefully look like it came that way. Steering column will have a u-joint under the dash (similar to new cars) and we will make up a bearing assembly to keep it concentric to the outer tube.

Engine Cradle Continued

Couple more updates from the past week.

Finally found a steering wheel for the cars.. been looking for a while on this one. Two reasons for this choice: the style is “somewhat” similar to the original with the single horizonal bar, and secondly Sparco has been clearing out some wheels on Ebay cheap so this made them affordable too. We’ll see what it looks like in the car I guess. The model is called “Veloce” and is leather with the perforated leather strip at the top.

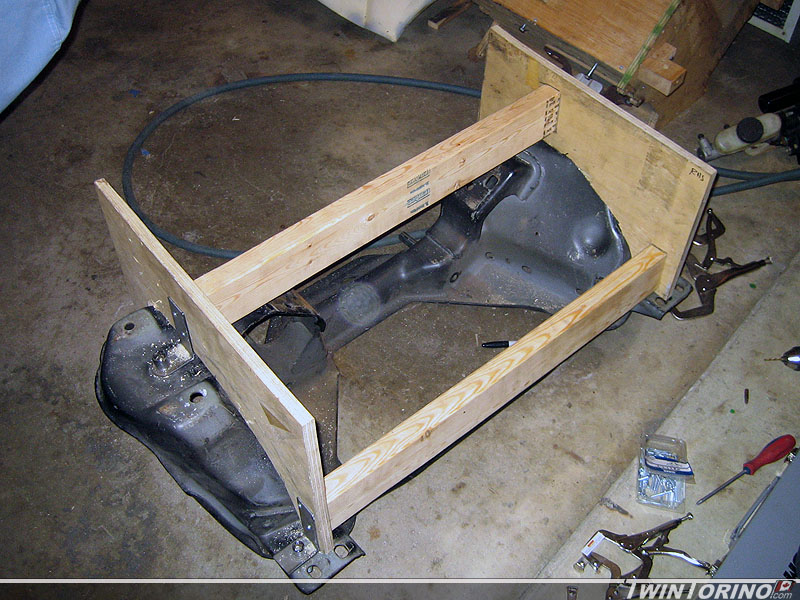

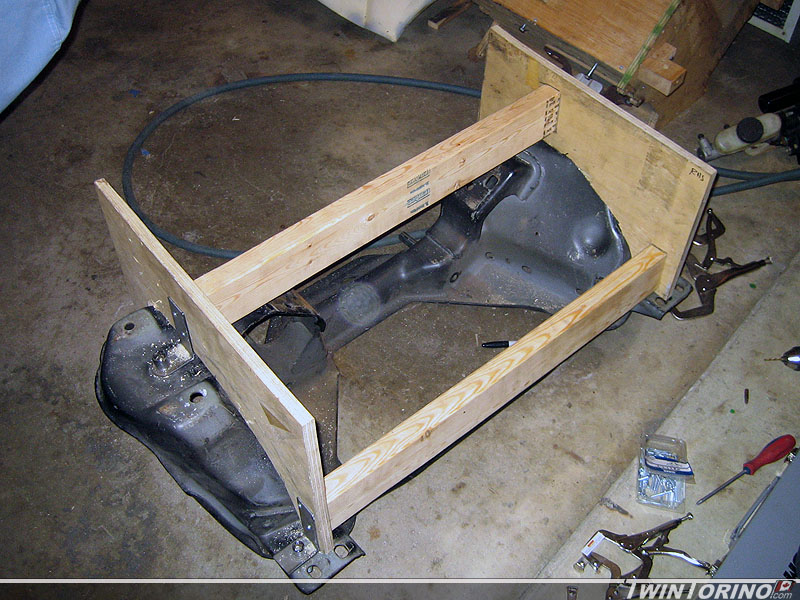

Moving right along on the front suspension. Pass side strut tower is done and ready to tack in. Next step was to make a perfectly centered and tight fitting k-member. The one we have been using to date is hacked up and really only for setting things up. Time to make another jig for this. As you can see, nothing too elaborate, but it serves it’s purpose. We used reference holes on the part used at the assembly plant to locate the jig. Then we made up 2×4’s that are the exact width between the frame rails. Finally two pieces of plywood are used to conform to the curves of the part. To use, the jig is placed on a Mustang K-member, sockets are placed in the 4 holes to located jig and then a utility knife blade is used to scribe lines on the parts. After that, we break out the plasma cutter and trim/grind to suit. Works like a charm! Making one for car #2 is now a breeze.

We used it to cut the k-member shown and it fits perfectly. That will make it very easy to weld in. Started on making up pieces to run under the frame rails to clean up the package and add a bit more stiffness. Kinda looks like the k-member was meant to be in there. Just need to make up the rear ones and the k-member will be ready to go in. Only thing left now is to weld in the filler panels and modify the motor mounts. After that, the front suspension is done!!

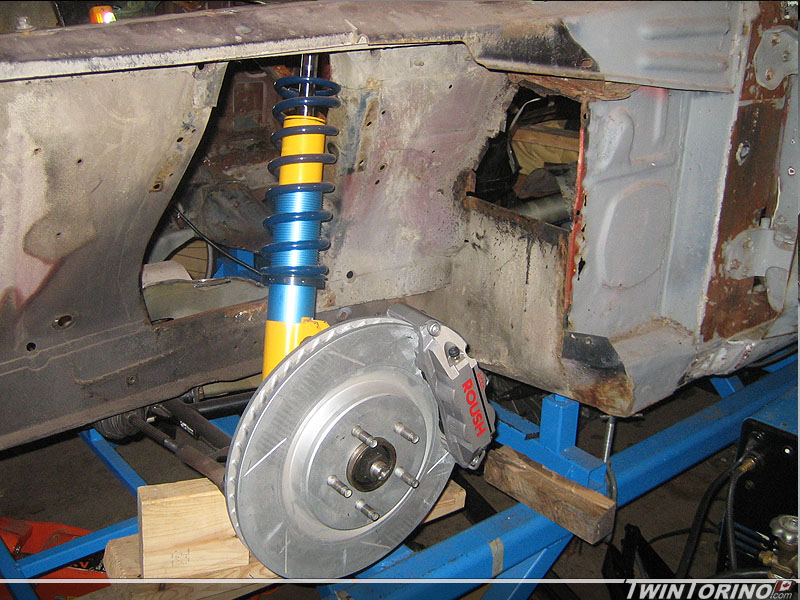

Steering, Brakes and Suspension

In the meantime – it was time to get going on the steering since this was somewhat of an unknown. The steering will be a cross between a 1968 column and 2004 Mustang. The column needs to be shortened to clear the pedels like on a Mustang, and also to line up with the rest of the system correctly and clear the headers. Beleive it or the column shaft on both are exactly the same. They use a 3/4 double d spec. This way it will require very little mods to get the universal joint to work with it. We will also use the steady bearing at the end like a Mustang. Just need to fab up a collar. I sacraficed the stock column shoft for now.. as I will eventually be using a floor shift column.

Found a home for the cruise control module behind the front wheel and inside the fender.

Getting ready to get the shock towers in too. Have all the suspension and tools needed now, so this will start shortly. Too bad 315’s won’t fit on the front of the car :). Need to find the exact position of the upper mount. To do this we will be building a jig off the front clip we have.