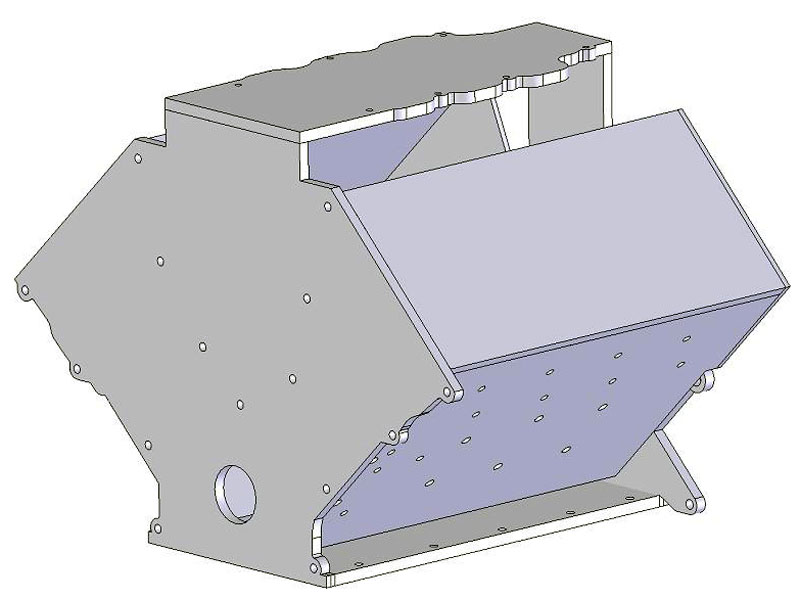

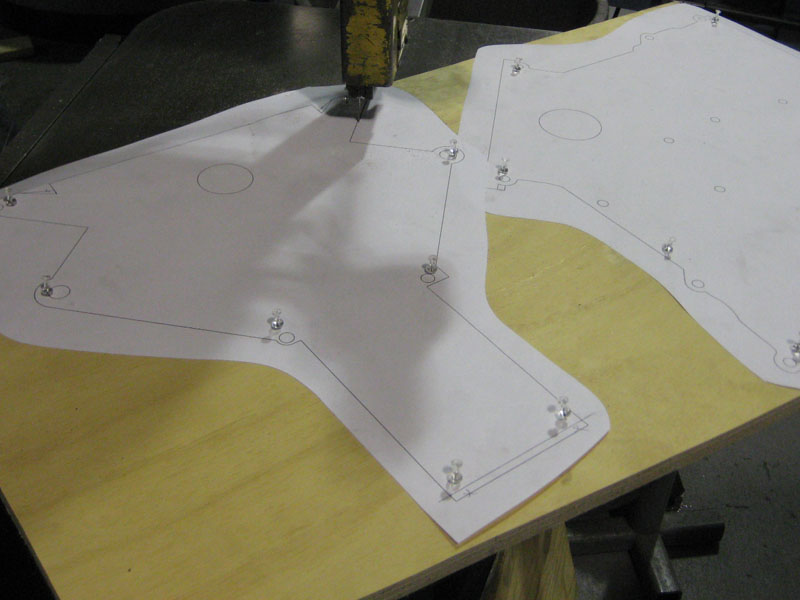

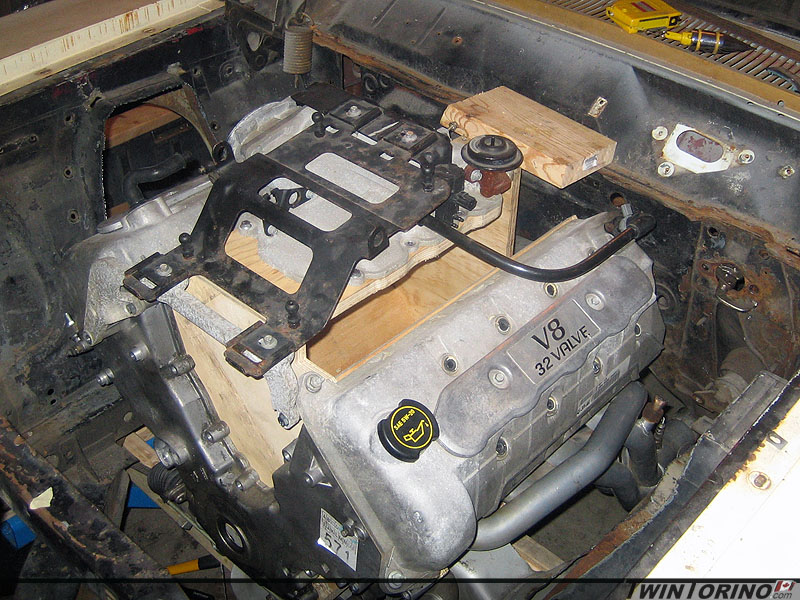

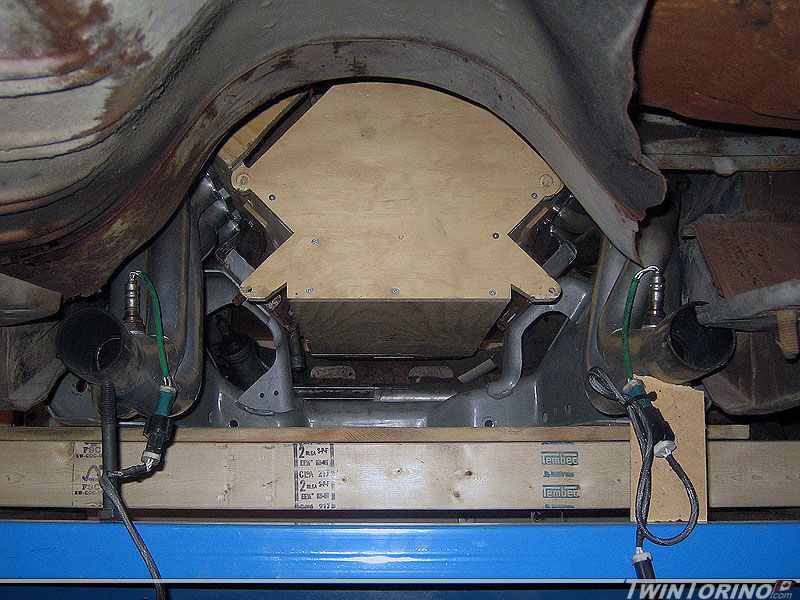

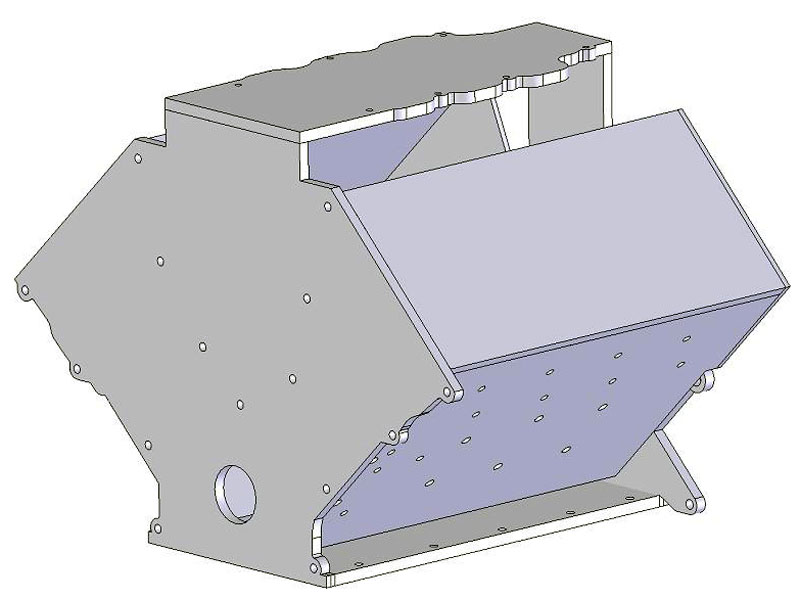

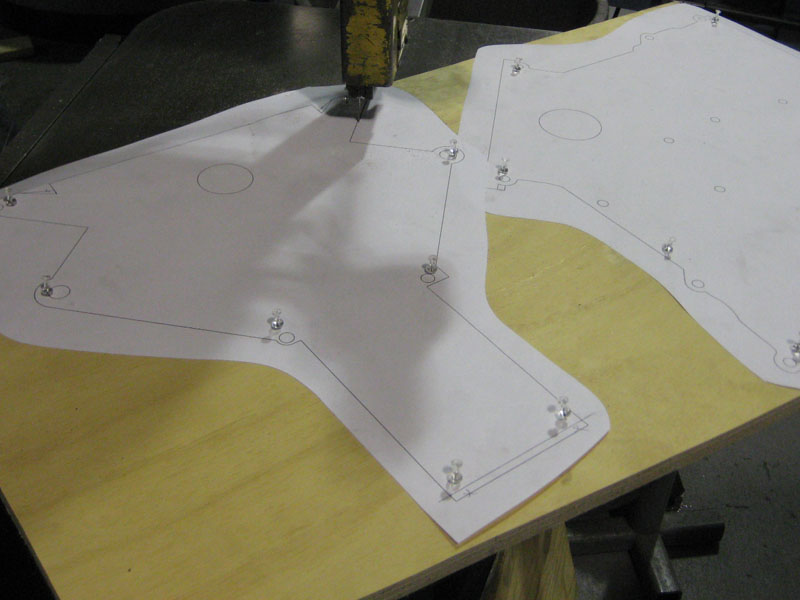

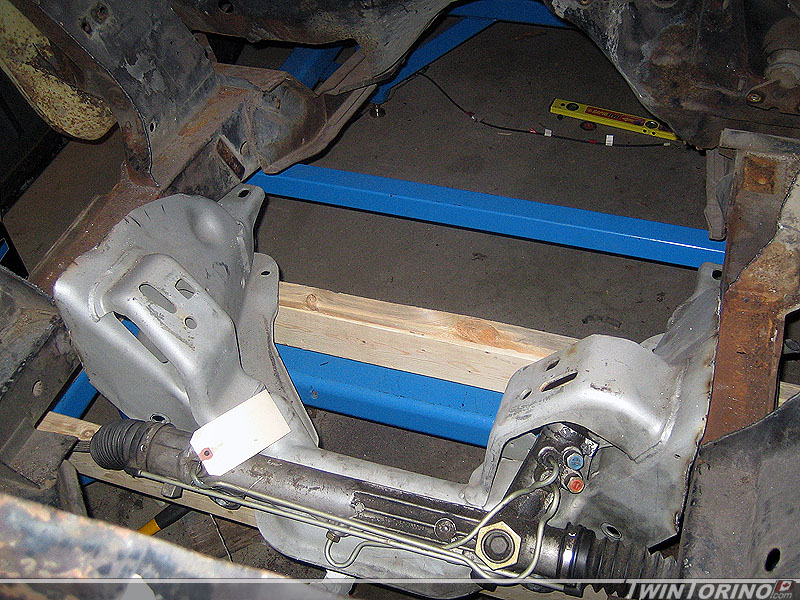

Got tired of trying to mock up the underhood area with a complete heavy engine, so I decided to make something a little more lightweight. A heavy engine was even more annoying to work with the car on a jig that is 18″ off the ground. Since I am on a tight budget, I opted to use an old shipping crate and about $10 worth of fasteners from Home Depot. After careful measurements of the block and tracing out various components, a CAD model was created. This was then used to make up 1:1 scale prints, which were in turn pinned to 3/4 plywood and cut out. This allows the headers, cam covers, trans, front cover, upper intake manifold, manifolds, A/C compressor and power steering pump to be installed in the car.

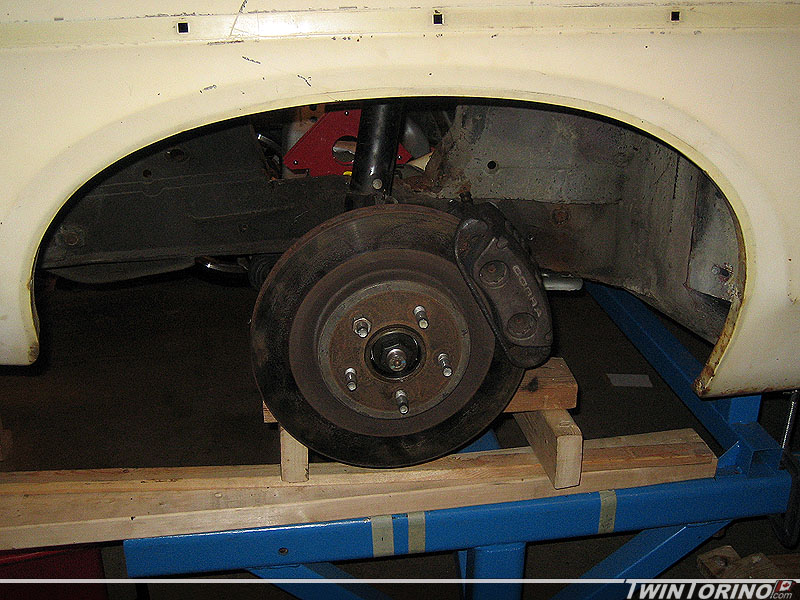

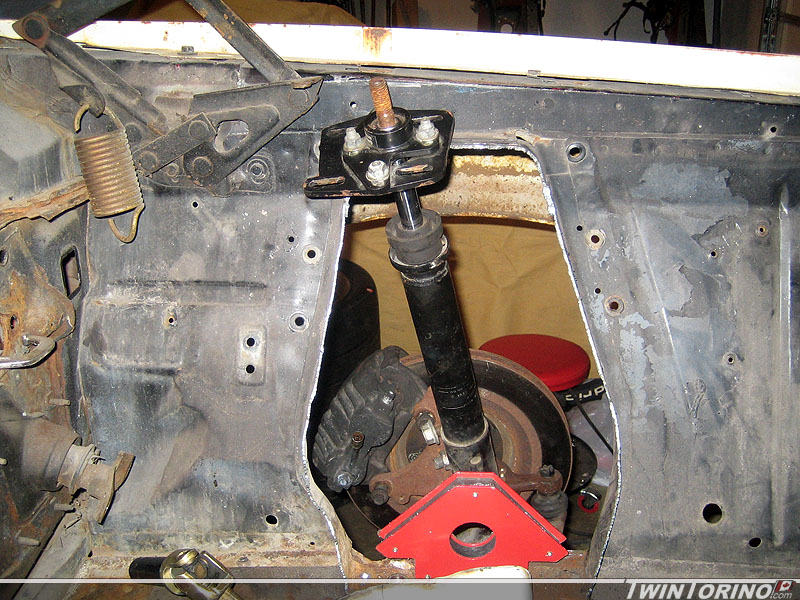

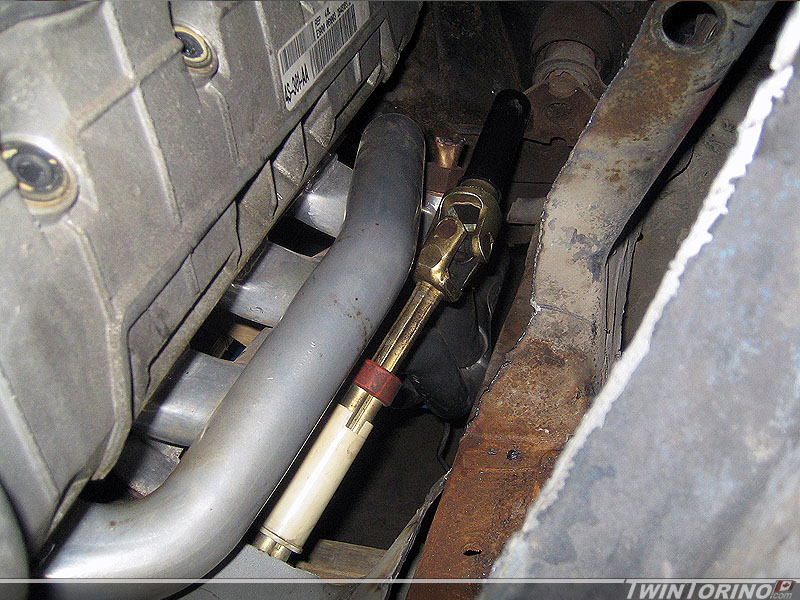

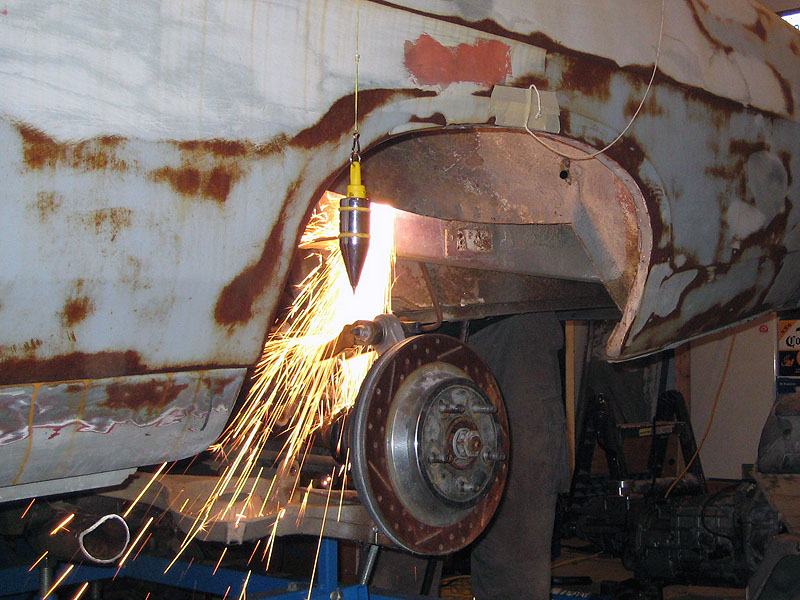

The shaker on the 2004 Mach 1 sits very far forward when in the Torino, so I had to take it apart and shift it back about 8″ to make it look right. Not sure if I am going to keep it on the car or not. The engine does not like the factory shock towers as you can see – the cam covers won’t fit (as expected). The plasma will make them go away.