Category: Brakes

Brakes and Fuel..

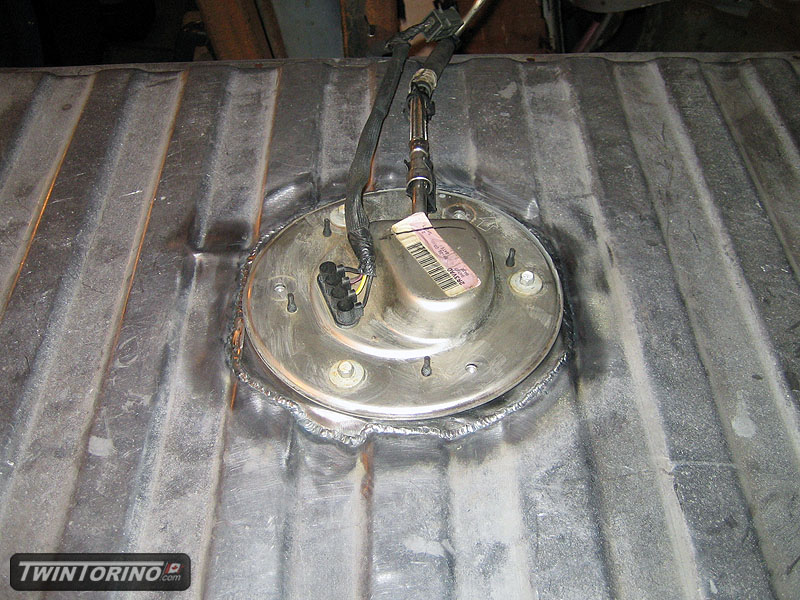

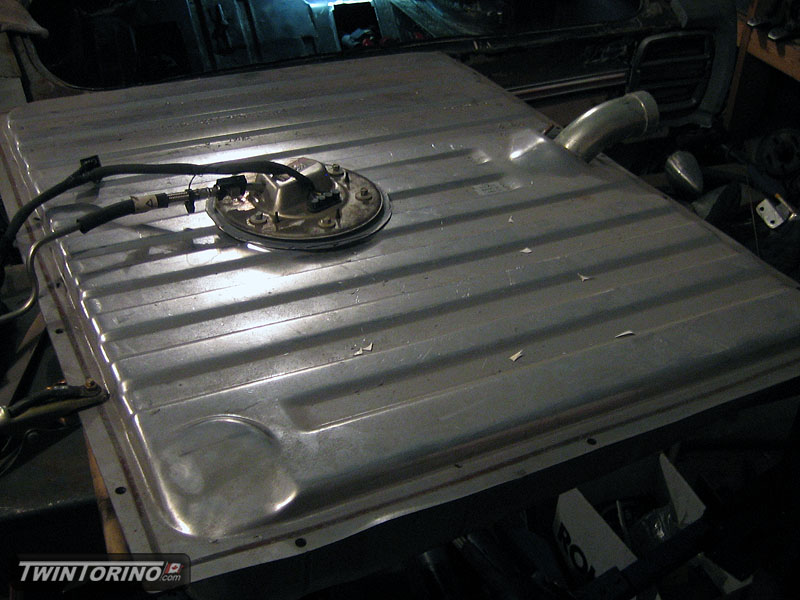

Have not posted in a while.. likely because we have been too busy working on the car. We have the fuel tank almost ready to bolt in, just need to weld on a modern filler neck/cap. The pump reservoir has been welded to the standard Torino gas tank to mimic the setup on a 2004 Mustang Cobra.

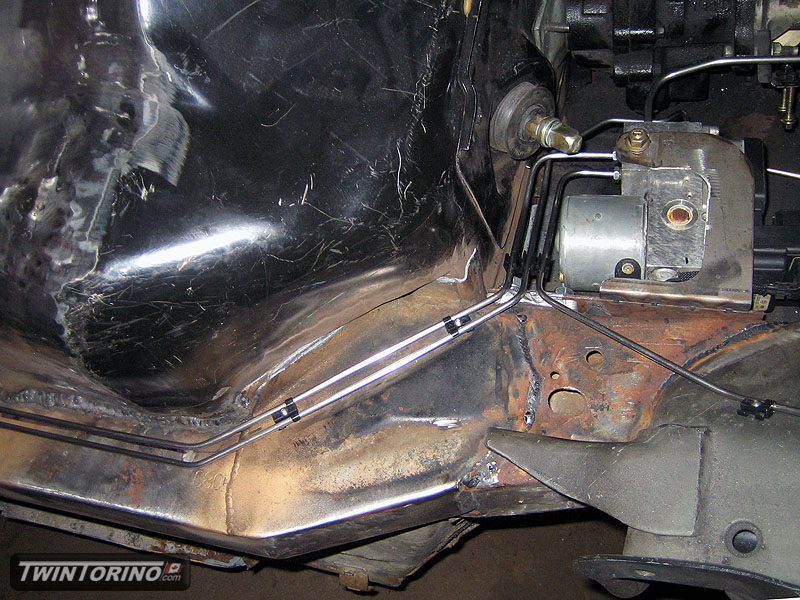

Brake system is for the most part complete, as all the necessary lines are bent up and attached to the car. Once the car is back on the ground, only thing to do now is bleed them.

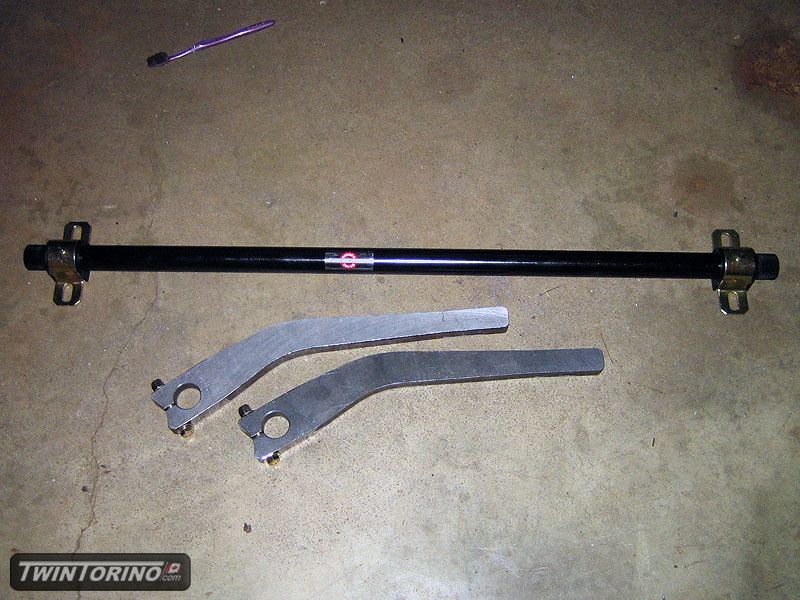

Splined swaybars arrived this week from Speedway – very nice parts. Looks like we are very close to having all the parts we need to complete 1 car – finally.

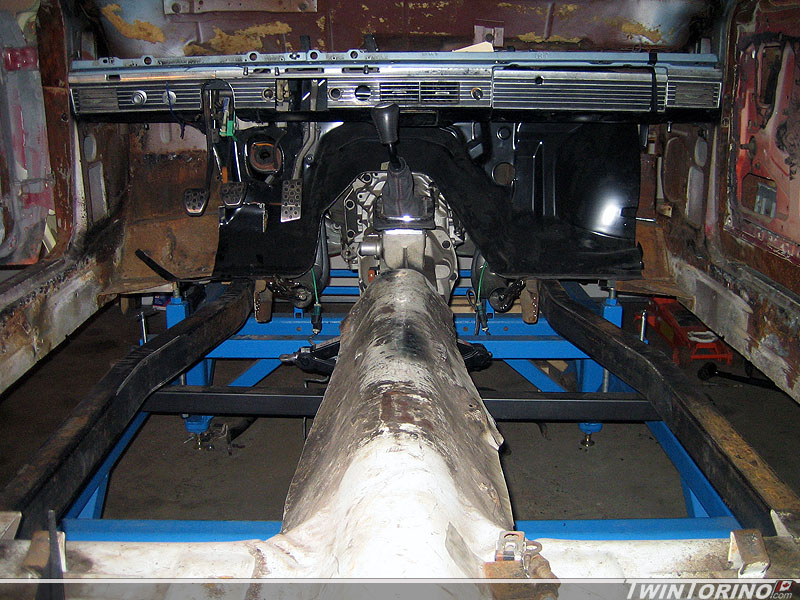

Magnaflow X-Pipe and E-Brake System

Moving right along, got the Magnaflow offroad X-pipe yesterday. Looks great and saves a ton of time trying to piece together straight sections and bends. As soon as the car comes off the rotisserie, the powertrain will go back in and exhaust will go on. Also got some straight 2.5″ SS pipe to make the Magnaflow system work since the Torino is longer than a Mustang.

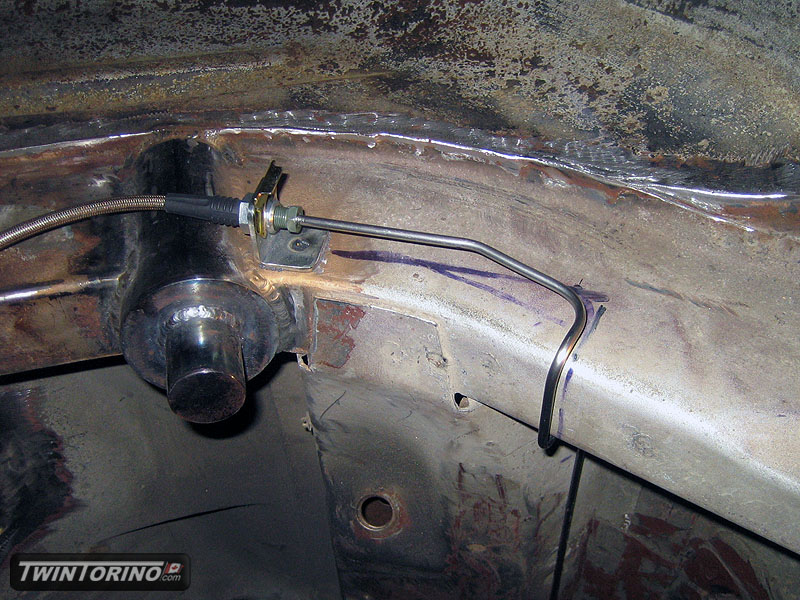

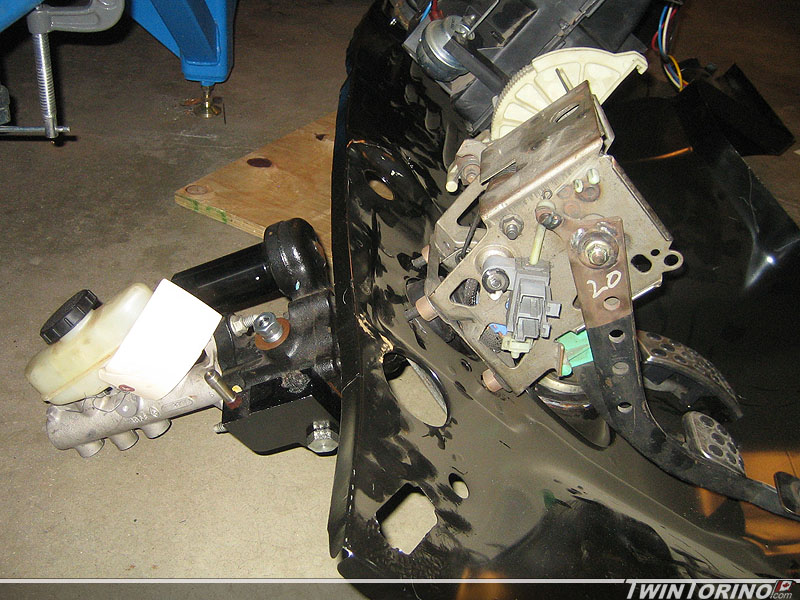

Moved onto the e-brake system. Went back and forth on whether to go on the floor in the pedal area, or in the console area. Since the car is clearly not going the stock route, function wins. Since we are not running consoles in the cars, and want a nice area for the dead pedal to go, it makes the most sense beside the driver. Besides, it makes e-brake drifting much easier :). Cables are aftermarket pieces for a 2004 Mustang with IRS.

We now have June in our sights for a cruise around the block..

ABS and upside down car..

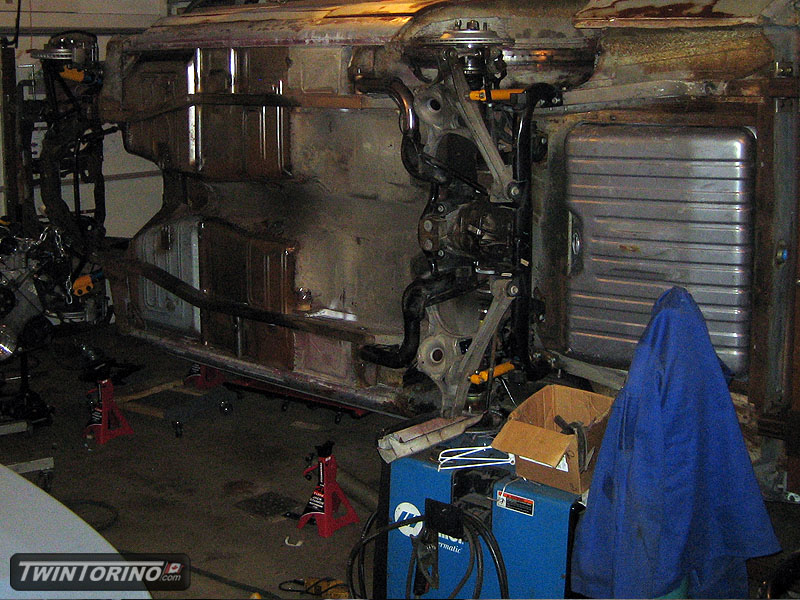

Finally finished up the worm gear setup on the rotisserie to allow the car to spin around and got to see what the rotisserie hype is all about. Sure is a nice tool to have around the garage! Unfortunately got carried away and forgot to drain the oil out of the diff. Now the garage has a wonderful 80/90 aroma.

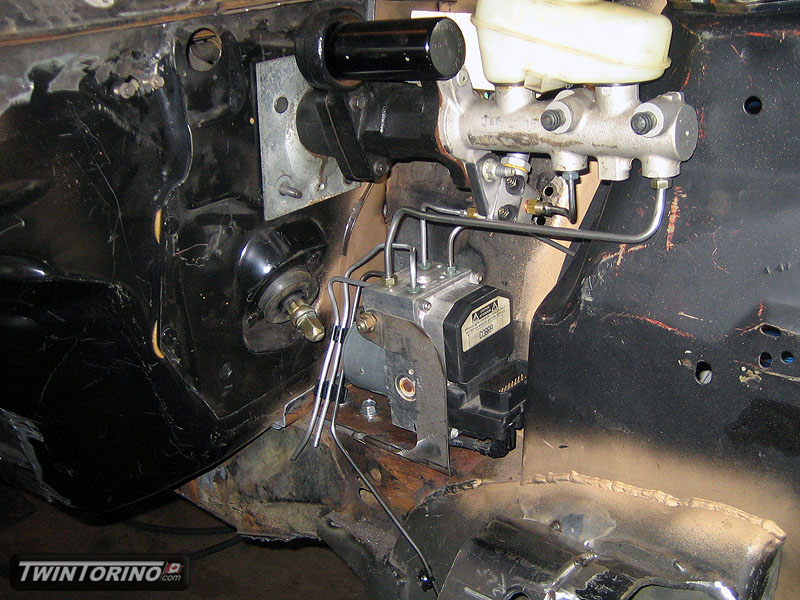

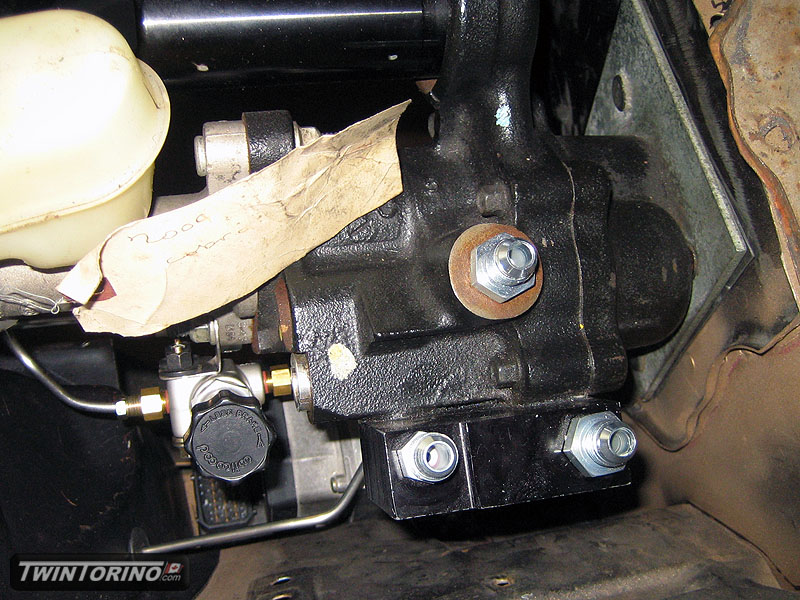

Moved on to getting the brakes in order. After searching far and wide for Torino brake line kits with ABS, we just ended up bending our own. Got the Wilwood proportioning valve in place, and also bent and flared up both front lines. Started routing the rear lines. We bent all of the lines up with 3/16 aliminum tube first which was 10x easier. Kinda looks like it was supposed to be there. Also got in the adapters to convert the hydroboost to AN style fittings.

Tank and lines..

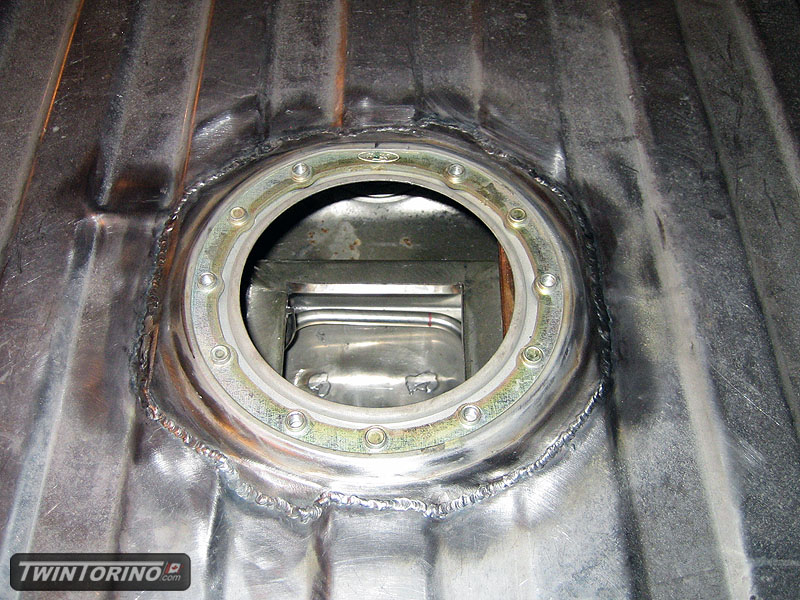

Started cutting up a new gas tank for the car and amazingly the 2004 Cobra fuel pump assmebly is the perfect height for these tanks. Just need to integrate a sump into the tank for the pump to sit in, and then modify the upper flange and weld into the tank. Surprised to see a “Made in Canada” tag on this tank, a pleasant surprise. Very nice quality part. Since the gastank is also the trunk floor in the this car, we will likely just make up a guard to protect the pump housing and lines.

Moving on – need to connect all of the systems together. Picked up some stainless 3/16″, 1/4″ and 3/8″ lines and found the appropriate clips, etc to attach to the car. This stainless tubing is seamless and annealed which makes it much more pleasant to flare. The Mustang has a wonderful mix of flare nuts, M10, M12, 3/8-24 and 7/16-24 to connect to the master cylinder, proportioning valve, ABS controller and all 4 corners. Since this is a 4-channel ABS system we also need to run 2 brake lines to the rear. Also have Goodrich front stainless flex lines and Maximum Motorsports in the rear.

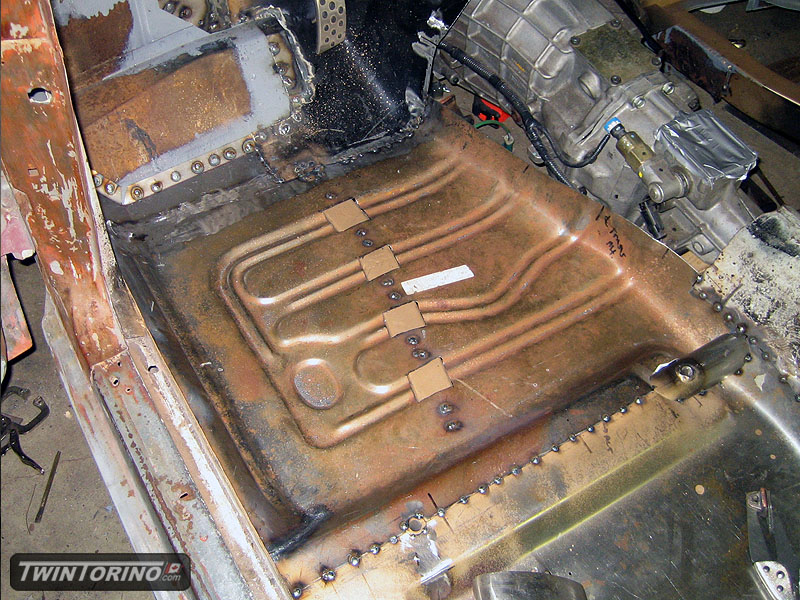

Floors and rust replacement..

Finally.. had lots more time lately to get things done. Summer will be here in no time.

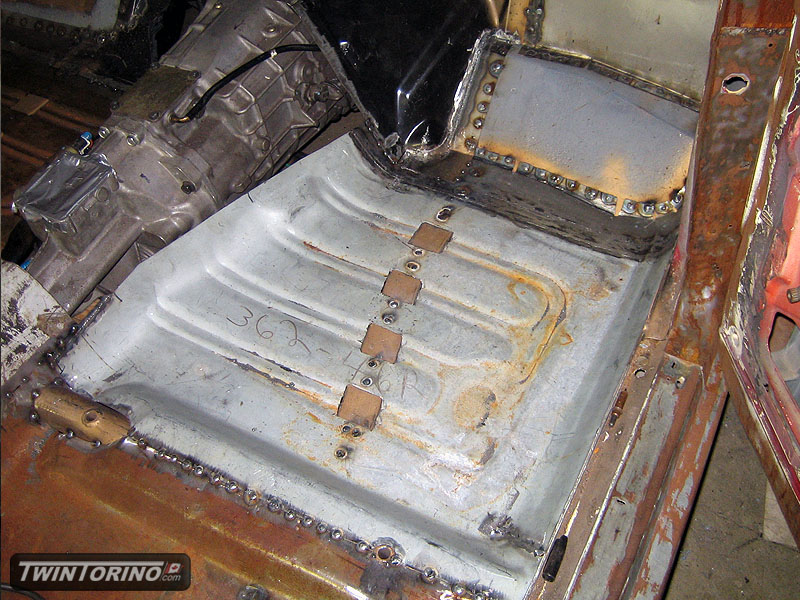

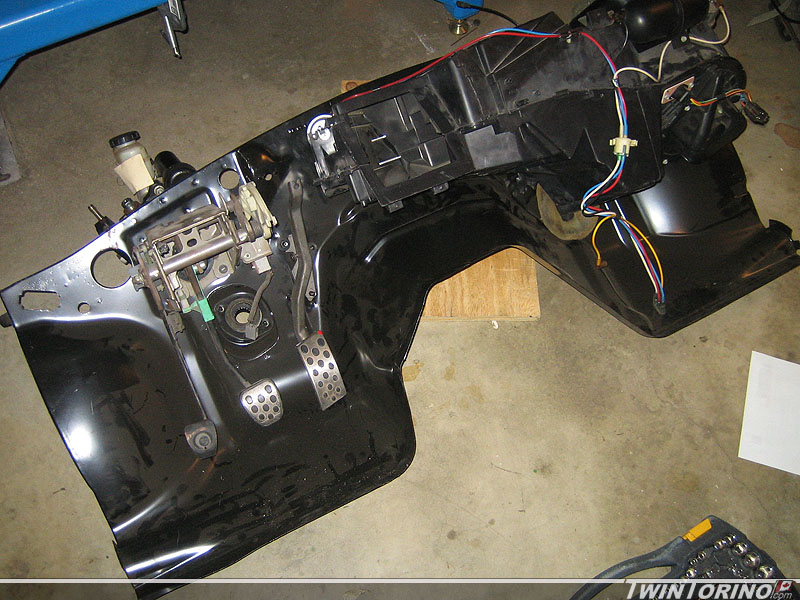

Firewall is now welded in for good, as are the front floor pans. Just need to final weld everything and also get the trans tunnel welded in. Plasma cut out some speaker holes and made up some patch panels. We got fed up with lack of access to the upper transmission bolts, so we made access holes through the firewall to get at them. Should make life easier.

Hydraboost fits like a glove. Need to run the lines to the power steering pump, steering rack and cooler next. Also need to get the pedal box to mate up with the Torino dash. We’ll be driving the car in no time..

Steering, Brakes and Suspension

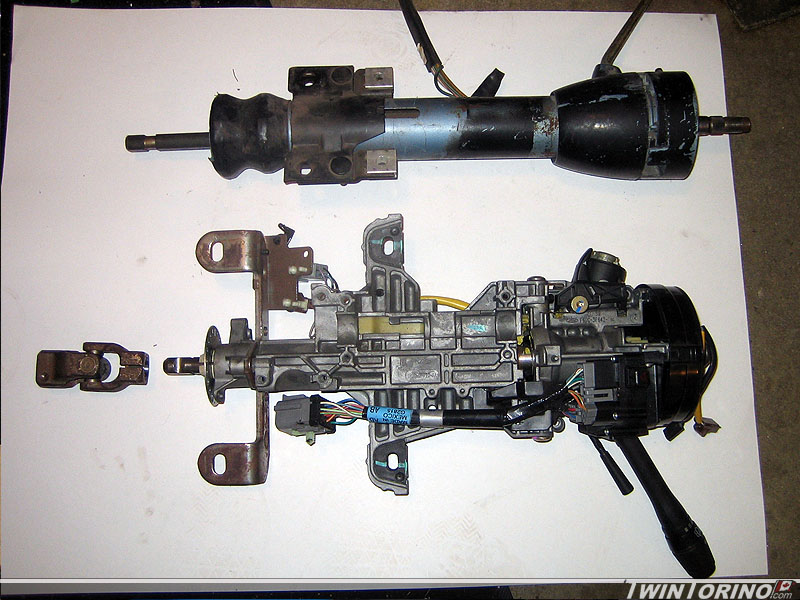

In the meantime – it was time to get going on the steering since this was somewhat of an unknown. The steering will be a cross between a 1968 column and 2004 Mustang. The column needs to be shortened to clear the pedels like on a Mustang, and also to line up with the rest of the system correctly and clear the headers. Beleive it or the column shaft on both are exactly the same. They use a 3/4 double d spec. This way it will require very little mods to get the universal joint to work with it. We will also use the steady bearing at the end like a Mustang. Just need to fab up a collar. I sacraficed the stock column shoft for now.. as I will eventually be using a floor shift column.

Found a home for the cruise control module behind the front wheel and inside the fender.

Getting ready to get the shock towers in too. Have all the suspension and tools needed now, so this will start shortly. Too bad 315’s won’t fit on the front of the car :). Need to find the exact position of the upper mount. To do this we will be building a jig off the front clip we have.

Suspension Brakes and Chassis Continue..

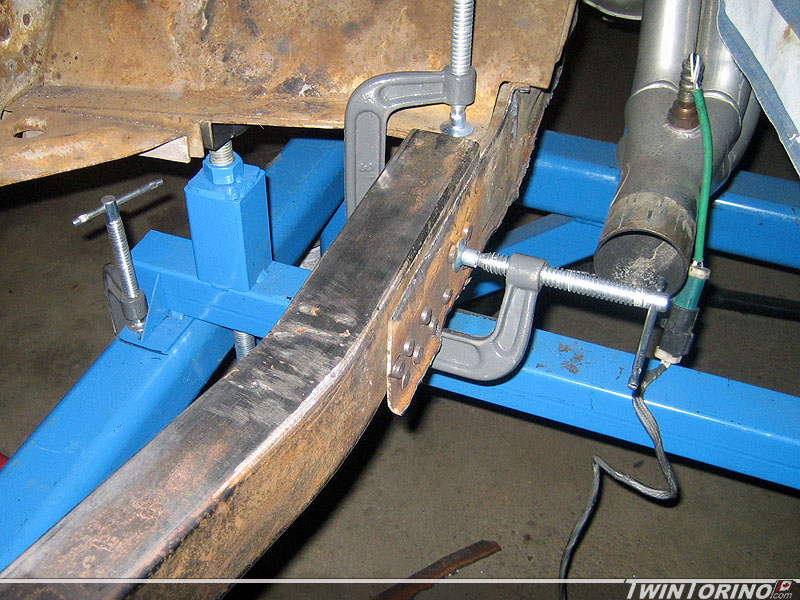

Made some more progress this week. Old trans mount brackets were modified so they now mate up with the subframe connectors. Once they are welded to the subframe connector – they should look like they are supposed to be there. This will also free up some room for the exhaust.

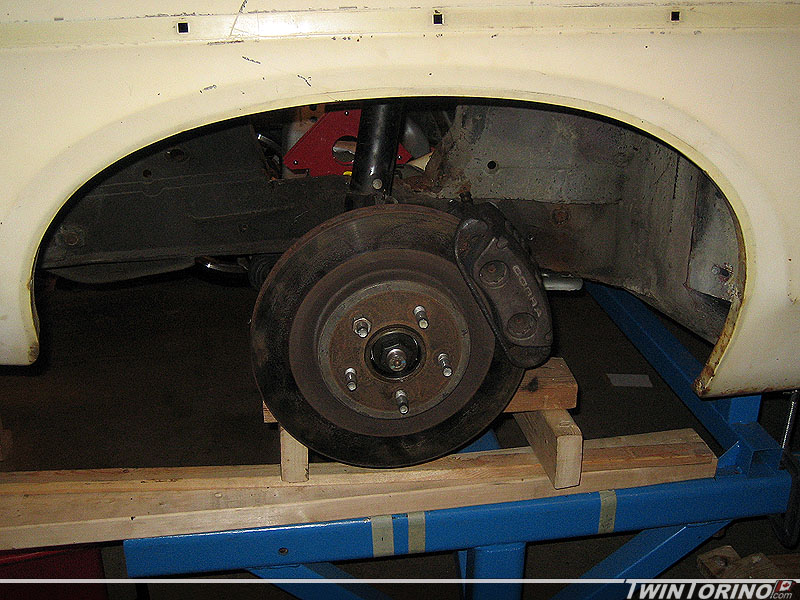

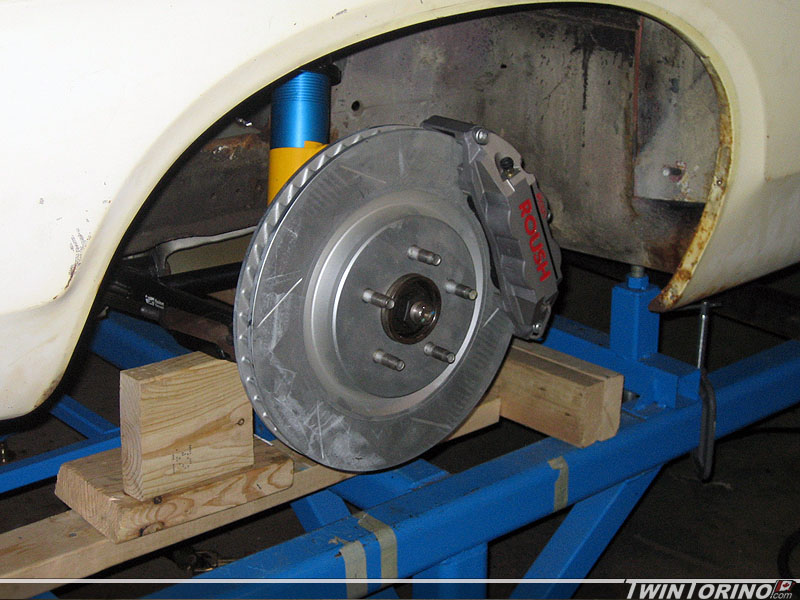

Driver’s and pass side connectors are now complete as well. Finished off the front IRS mounting bracket piece that fits into the old leaf spring pocket. Just need to be welded once everything is assembled on the vehicle. Also mounted up the rear 13″ rotors – as expected they need to mached to work in our applicaition (since they were designed for a car with Mustang GT brakes and not Cobra brakes). The caliper sits too high as you can clearly see.

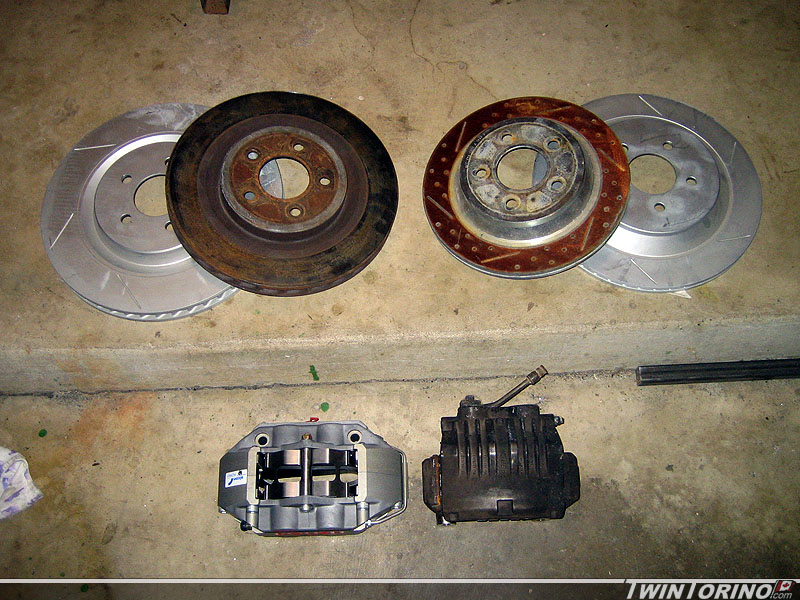

Roush Alcon Brakes..

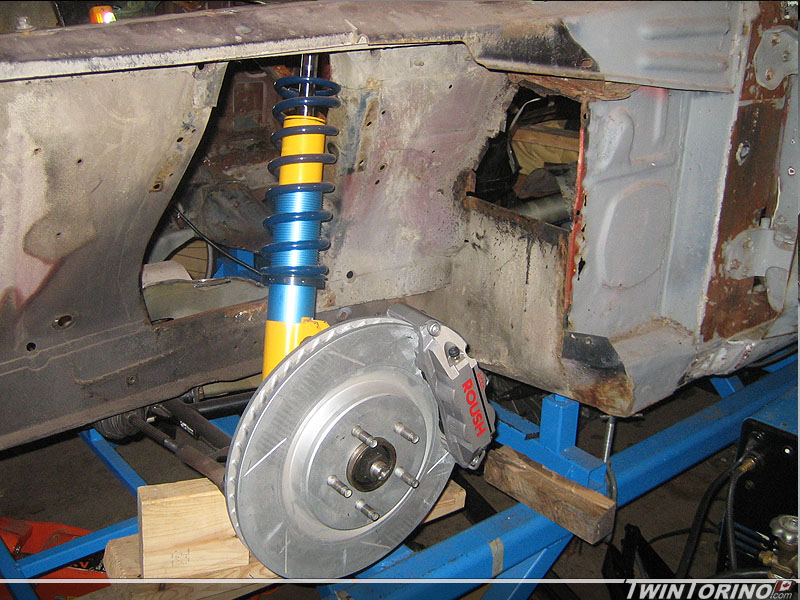

Well.. I typically run on a tight budget and hate to buy anything new.. but I had to make an exception. I found this set (technically 2 sets I guess) of Roush Alcon brakes at a great price on clearance. I just had to have them. The calipers and rotors and made by Alcon, and the misc hardware and mounting brackets are made by Roush. This kit is made for the Roush Stage 3 Mustangs from 1999-2004 (SN95). The front rotors are 14″ (compared to the 13″ Cobras) and the rears are 13″ (compared to the 11.65″ Cobras). The calipers are 4 piston with race/track pads. Can’t wait to see how these work. The barely fit within the 18″ FR500 wheels. I have had issues in the past with melting the dust boots on the Cobra brakes, so hopefully that problem will go away.

How big are 14″ rotors? They are the same size as the rims on a 1969 Camaro..

MUstang Firewall and Brakes..

After going back and forth on how to make these pedals work out, along with the clutch cable, gas pedal & cable, heater box, wiring harnesses, steering column pass through etc. etc, we can to the conclusion that the firewall would likely be hacked to pieces by the time we got done with it. If only we had a firewall from a Mustang. We had two that were already part of a complete car, but those have lots of other pieces spot welded to them and they would likely be ruined trying to get the out, let alone how long it would take. I put a call into a friend who works at a dealer, and the next thing I know he was telling me that firewalls are available and are cheap! I guess when you think about it – how often would a firewall be replaced? Are car would likely be written off before needing to replace one. As you can see below – everything wil bolt up nicely and look like it was supposed to be there. Obviously this is not a quick bolt on modification and will require lots of cutting and welding, but it will be worth it in the end for sure. In the end, the cost of the firewall was less than 2 replacement Torino toe pans, so this was a no brainer.

Front Suspension Mockup..

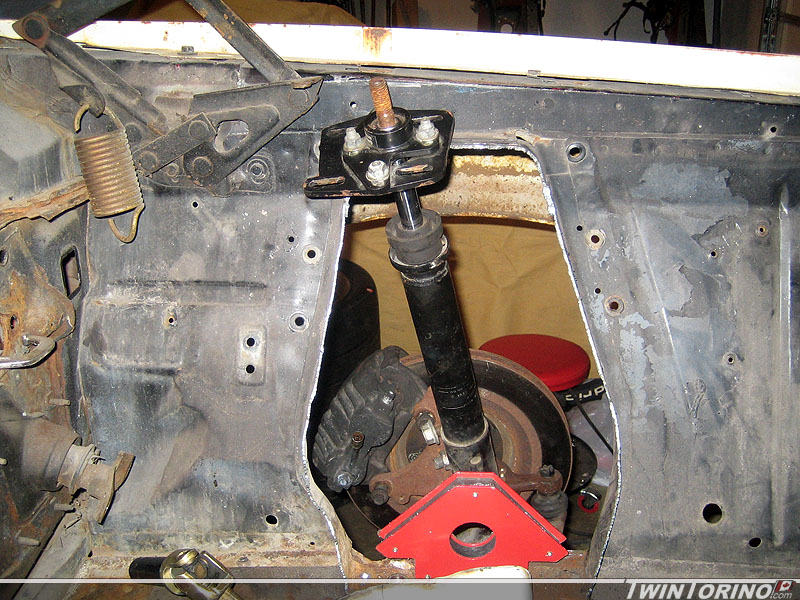

Started to mock up the front suspension by putting the control arms in place as well as the spindles, hubs, struts, caster/camber plates and brakes. The suspension is sitting approx where it will in the shock tower area. Next step is to finalize these points with a plumb bob to match the same points as a stock 2004 Mustang. Then it is time to build up costom strut towers. The struts shown are just for mockup. In the end the car will be running coil over struts with adjustable rebound and compression (Koni or Tokico – haven’t decided yet). The Maximum Motorsports caster camber plates will allow us to run 2-3° of camber at the track and then back to close to stock specs for the street. The only immediate problem is going to be with the hood hinges interfering with caster/camber plates. One thing we did figure out here is that a SN95 Mustang swaybar is not going to work here since the Torino framerails are much lower than the Mustang, so I think we are going to have to run an S197 Mustang bar instead.