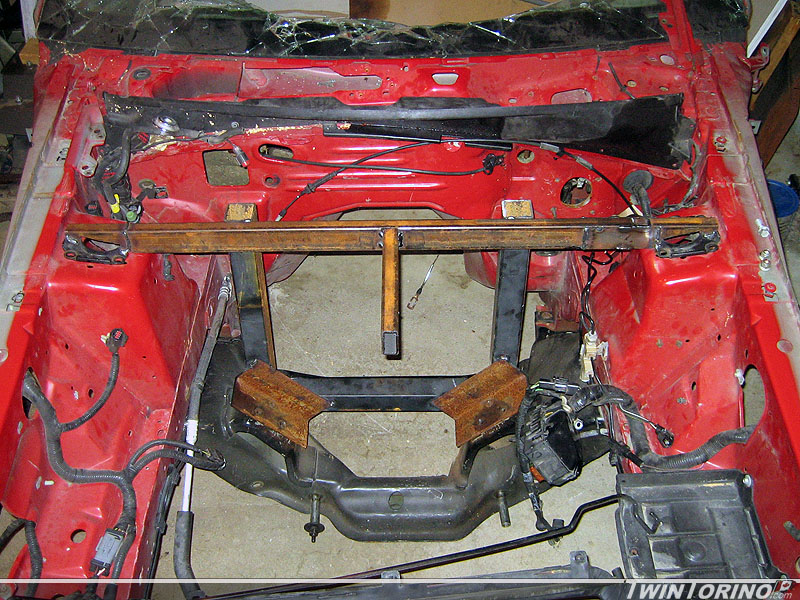

Been working away at the front suspension a lot lately.. although it does not feel like I am getting anywhere. Decided that using the stock k-member will be almost as complicated in the end as just building one from scratch. Making brackets to mate up to the Torino frame and also shifting the engine back 3.25″ relative to where it would be on a Mustang have been the biggest headaches.

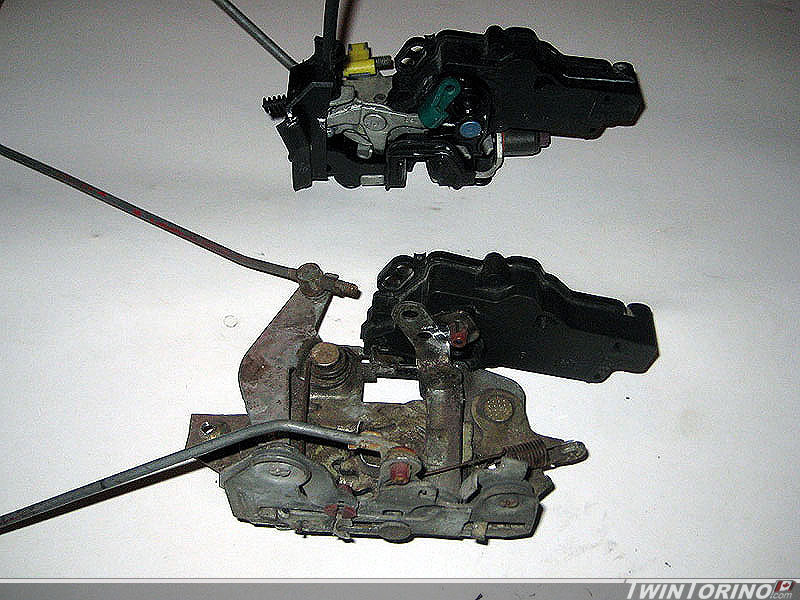

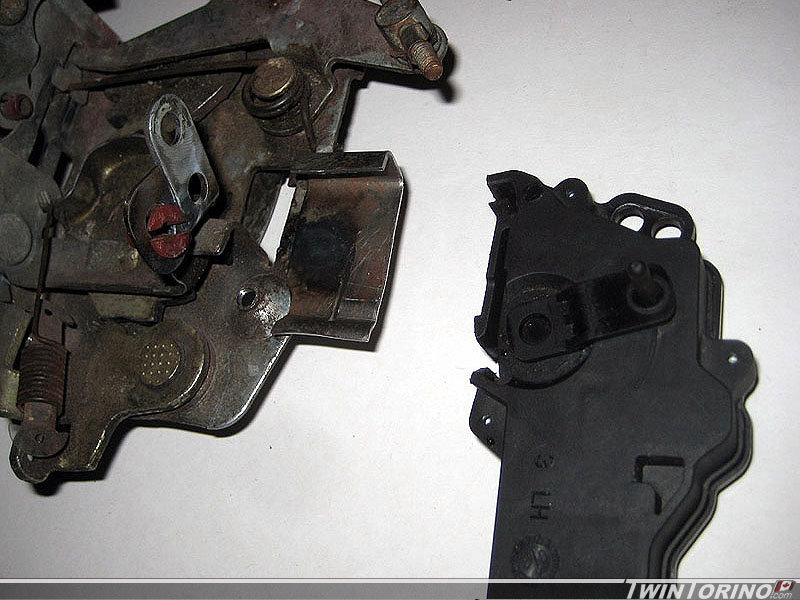

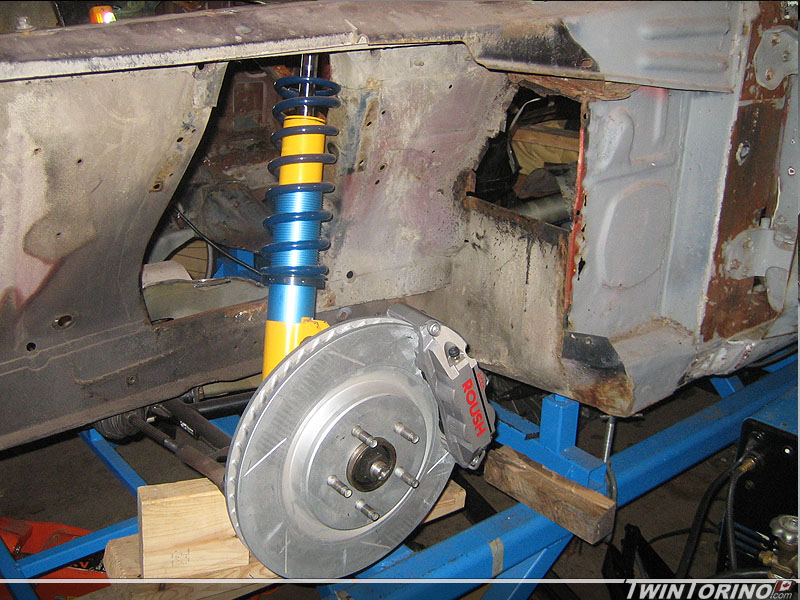

We decided to switch to shorter control arms to be able to fit larger tires up front (265’s or 275’s). This has been a pain because the fender lip is low and covers the top outside edge of the tire, and also the tire hits the coil-over spring on the inside. While the outer lip is fine if you chose to only drive straight – as soon as you turn the tires would scrap on the fender. Four options to get out of this one. 1) Accept a tire size of 245 or less. 2) Add flares to the sheetmetal 3) Move strut inboard via shorter control arms. 4) Bail out on the suspension package and try another one. 1 and 2 we were not willing to accept, and 4 was too expensive and we didn’t want to have to work with a mystery suspension design. Turns out option 3 was easier than we thought as we can just use 79-93 Fox body Mustang tubular control arms which are .9″ shorter.

We ended up finding a used set of Maximum Motorsports Fox body tubular control arms used online. These actually have a forward offset of .75″ in addition (ball joint moves ahead, pivot points stay in the same place) meaning we could squeeze a bit more caster out of them. The only reason these work for us is because we can put the shock towers anywhere we want them and can achieve the camber we need. This would not be the case if you were to start with a 94-04 Mustang and add 79-93 control arms.

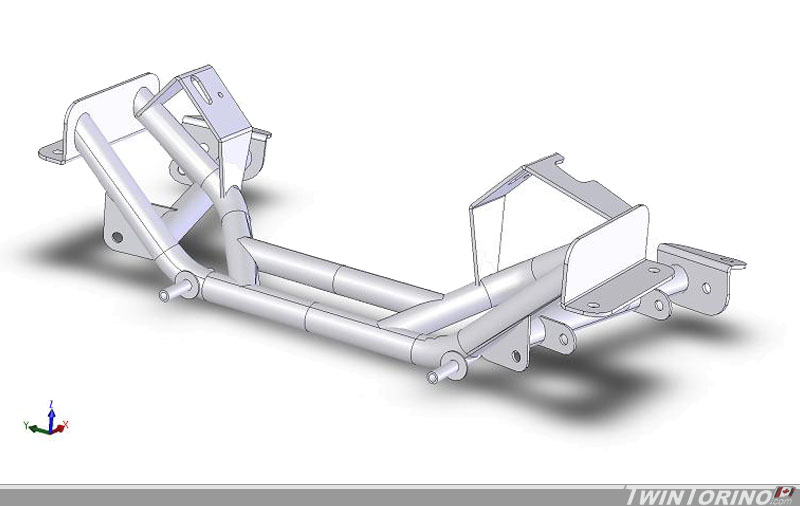

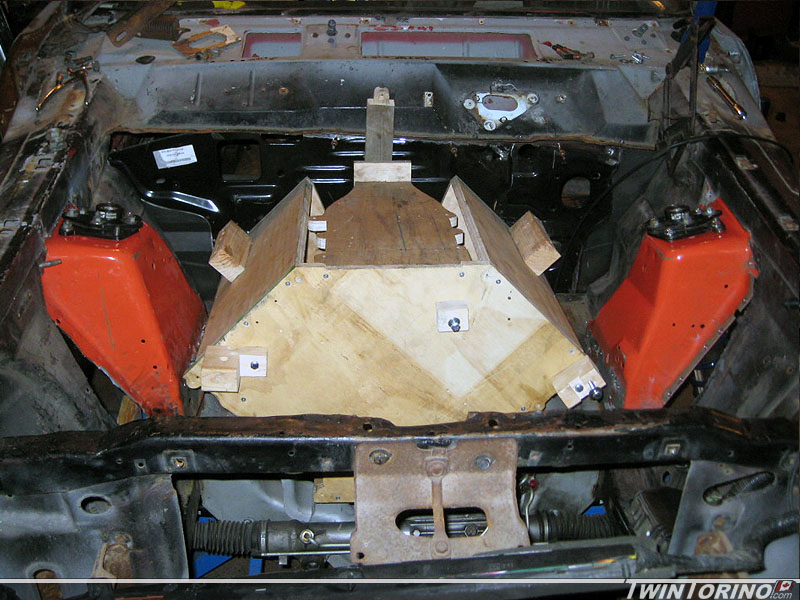

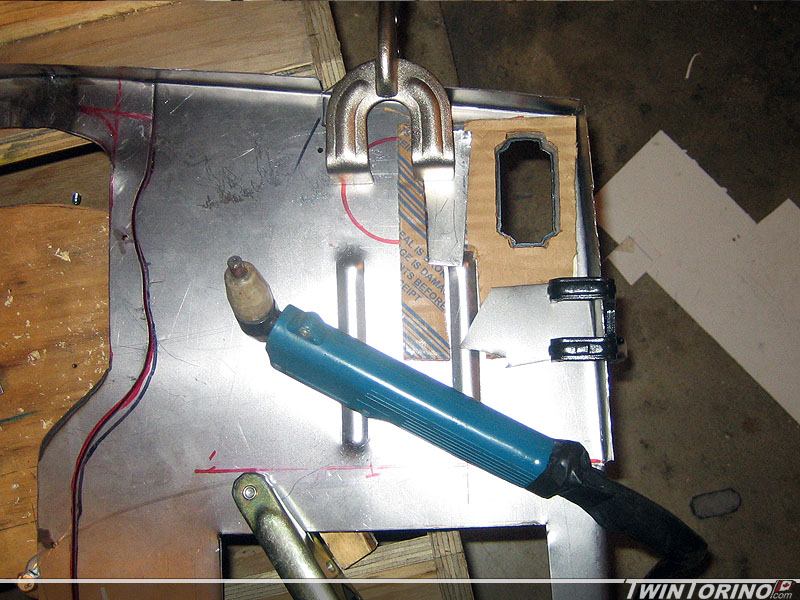

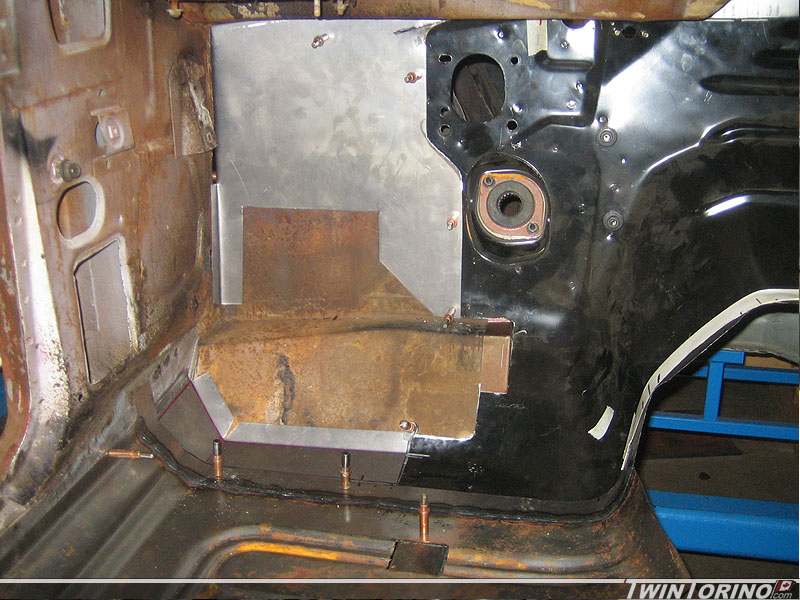

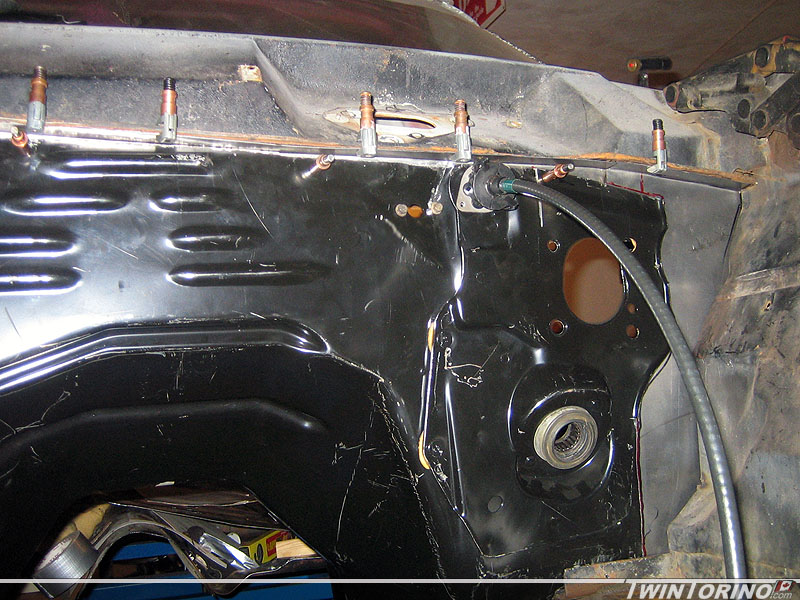

After doing lots of measuring and thinking.. I almost have a design that is ready to build. This will bolt into the stock Torino frame rails in the front. Just need to weld in sleeves into the frame. This will clear the oilpan, headers, steering linkage and move the engine back 3.25″ and allow all the suspension to bolt up where it needs to go. It will also clear the alternator (which is low on the Roush kit), oil filter, lower rad hose and A/C compressor. Once we build a jig for this – we should be able to make copies pretty easily for future projects.