Category: Chassis

Floors and Seating..

Three main things on the go right now – front suspension/steering/brakes, floor of car/subframe connectors and steering column/pedal setup and seat positioning. Rear suspension is on hold until custom bent tubes and rear coil overs arrive.

First the suspension. Have found most of the front suspension components online in the past month or so. Nice thing here is since I am running SN95 (1994-2004) Mustang based suspension – the sky is the limit with aftermarket parts.

Front suspension will consist of (parts are on the way or in hand now for one car):

Maximum Motorsports front tubular lower control arms

Koni dual adjustable (DA) front struts with adjustable rebound and compression damping

Maximum Motorsports coil over kit

Maximum Motorsports caster camber plates

Stock Mustang front spindles/hubs

Since the strut rods are no longer needed, the brackets that house the bushings were removed. Custom brackets will be made up to stiffen the the area once again and also provide mounts for the radiator, A/C condensor and ABS unit.

With the suspension almost in position, the stock control arms make contact with the frame. Tubular control arms correct this issue, although just barely. THe goal here is to get the suspension in the exact same position as in a stock Mustang to keep the suspension geometry the same (easier said than done as we are finding out)

Nearly new tubular control arms compared to the old ones. Since we are running coil overs, spring pockets are no longer needed. They are also lighter.

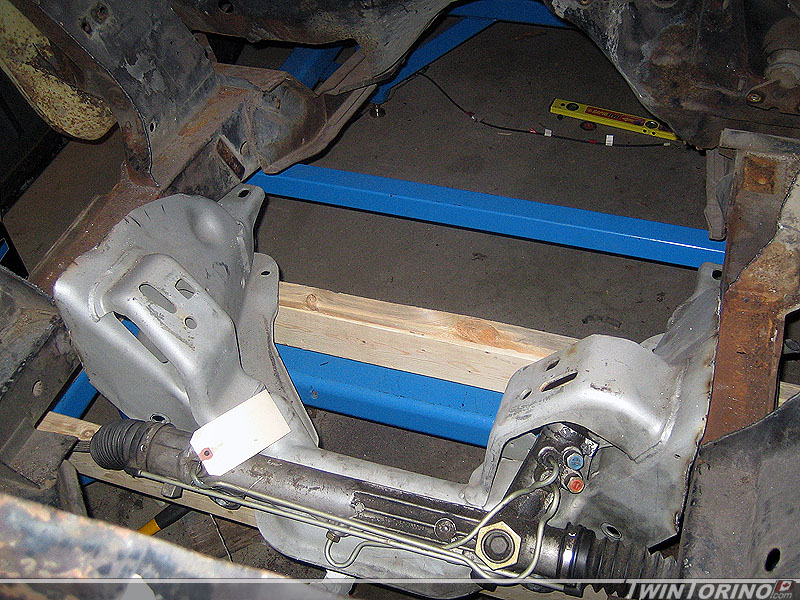

As for the subframe connectors – hoping to have them in within the next week or so. The passengers side is nearly ready to go in. Just have to jog the subframe connector 4″ as the front subframe is 4″ inboard of the rear (more to come on that shortly). As you can see, the front trans mount has been removed, and the remaining piece left will be used for welding to the connectors. A custom trans mount will need to be made for the 6-speed, and also a driveshaft loop needs to go in as well as seat mount supports. This will all make a bit more sense once they start going in.

Got started on laying out the driving position this week as well.

Starting fitting the Sparco’s into the car. They are extremely comfortable and will help keep a person planted when on the road course. Stangely enough, sparco does not make seat adapters to bolt into a Torino, even though the model name is Sparco Torino :).

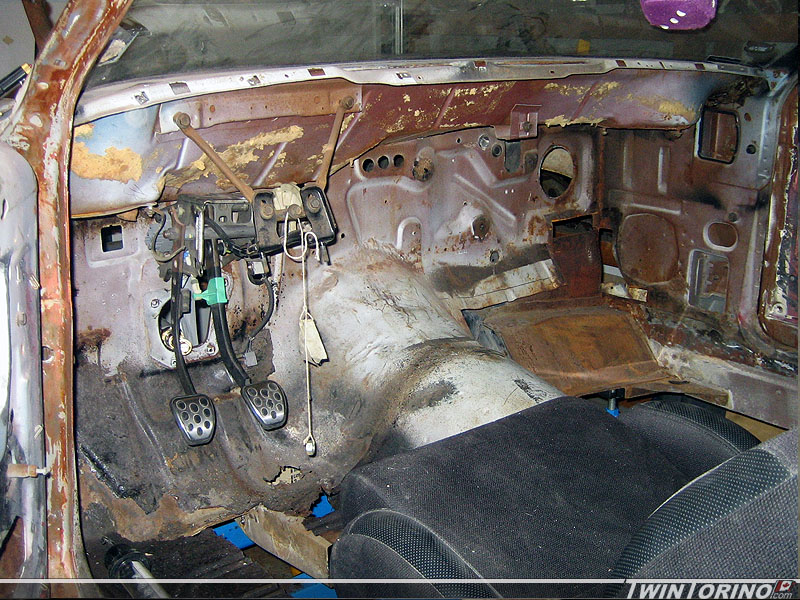

Started to fit the Mustang pedals into the car. Several reasons for using these instead of Torino ones. Mustang uses a cable clutch and Torino ones need significant mods to make work with the clutch quadrant. Want to be able to keep the stock Mustang pedal ratios going into the hydroboost. Want to be able to use the stock Mustang electronics since all the dash wiring is from a 2004 Mustang. Also like the pedal positions much more and they are much better for heel/toe driving on the track. Measurements were taken from a 2004 Mustang to be able to position the pedals the same distance from the firewall, height off the ground, and releationship to the steering wheel. The goal here is also to use a stock floor shift Torino column as I hate the look of a new column in an old car.

Well.. here is the first issue as we were expecting. The clutch quadrant hits the windshield wiper motor area. This area will need to be modified to make it work. It is looking like we will end up grafting a Mustang firewall onto the Torino. That way everything will bolt right up (including brake clutch and gas pedals, steering column, hydroboost unit, heater box and all wiring and cable pass throughs) and look much cleaner. Since we have 2 complete Mustang firewall assemblies and a plasma cutter.. this should not be a big deal.. famous last words I guess.

Stay tuned..

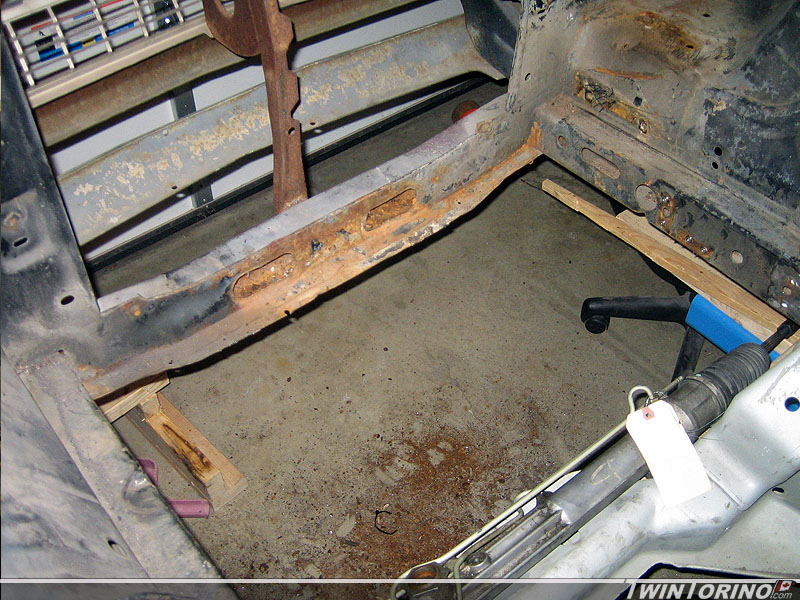

Making the Floors Go Away.. Adding Some Stiffness..

That’s the story.. now some progress.

Floors be gone:

Soon to be subframe connectors:

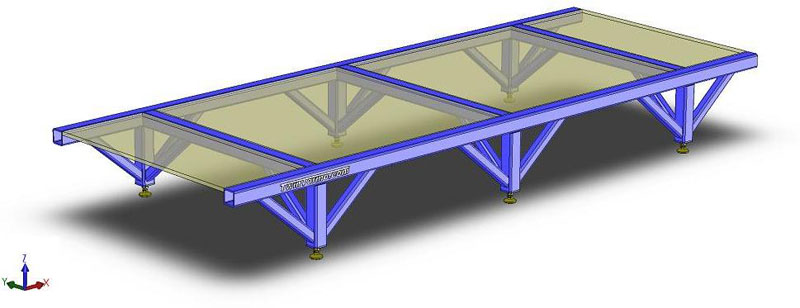

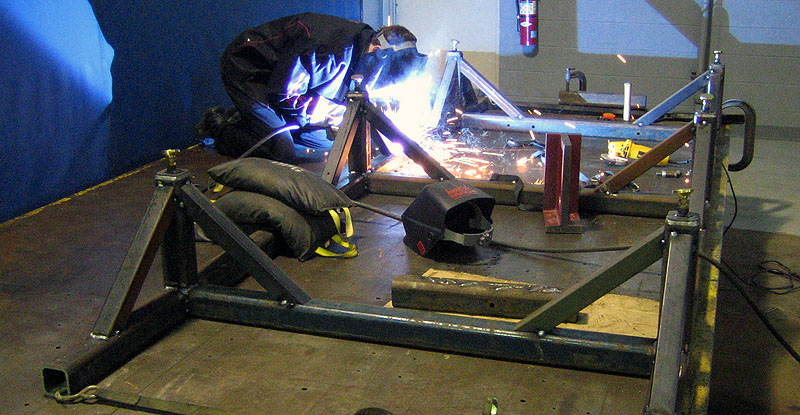

Custom chassis fixture for setting up suspension and powertrain:

IRS cradle fixture:

IRS moving into place..

Finally starting to get some useful work done on the cars after all the detours of project funding, fixture building a parts sourcing. It has been a long road that has brought us through many provinces and states.

Making Room for the Powertrain..

If you look at the previous pictures, you will see that a DOHC engine was not meant to fit within Torino shock towers. Easy solution there – get rid of them. They will be replaced with 2004 Mustang based ones.

I will say once again how great a tool a plasma cutter is!! This is by far one of the best and fastest tools I own. It makes cutting up cars a breeze. Once the shock towers were out, the stock Mustang k-member was modified to allow it to bolt into the Torino. A spare mockup steering rack was placed in position and will work perfect once in place which is another relief as we were not sure if it would hit anything.