Finished tacking in the pass side wheel well and made up the shock mount for that side too. Everything is ready for final weld. Time to move back to something we have been putting off for a while now – spring mounts, spring sizing and locking in the ride height with all these parts which turned out to be easier said than done. As you can see – we ended up making a new upper spring mount to clean things up and transition it into the existing frame.

Three main parts to the rear suspension travel – and each stage has it’s own issues:

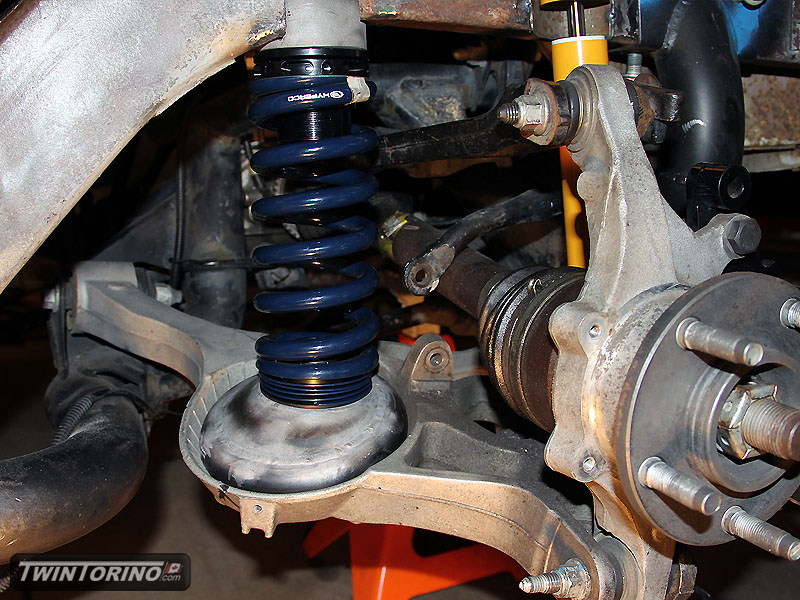

Rebound/full droop position – this is with the wheel pushed all the way down. The car will rarely see this position, but is is possible and will always occur when lifting thcar in the air using a hoist. The first issue we ran into is that our springs are too stiff and the spring will just fall out of the car as is as they are all their free length at this position. Simple solution – just buy longer springs right? Unfortunately not that easy – if you get longer springs, the car will just sit that much higher. Since the motion ratio is approx 0.5, if you make the spring .5″ longer, the car rides 1″ higher. Solution here is to run Hypercoil helper springs. You can completely compress these springs by hand, but there is enough spring force to keep the main sping in place. They compress to a mere 0.3″. The keep the lower spring in place on the lower mount – we opted to use a nylon part made by Vorshlag which some may recognise as a BMW parts supplier. To keep these in place, we just made up 1 3/8″ posts as you can see in one of the final pics. We also used a similar sized spacer to keep the ride height adjuster in place. The other key point about this position is still being able to get the spring adjuster in position on the top post.

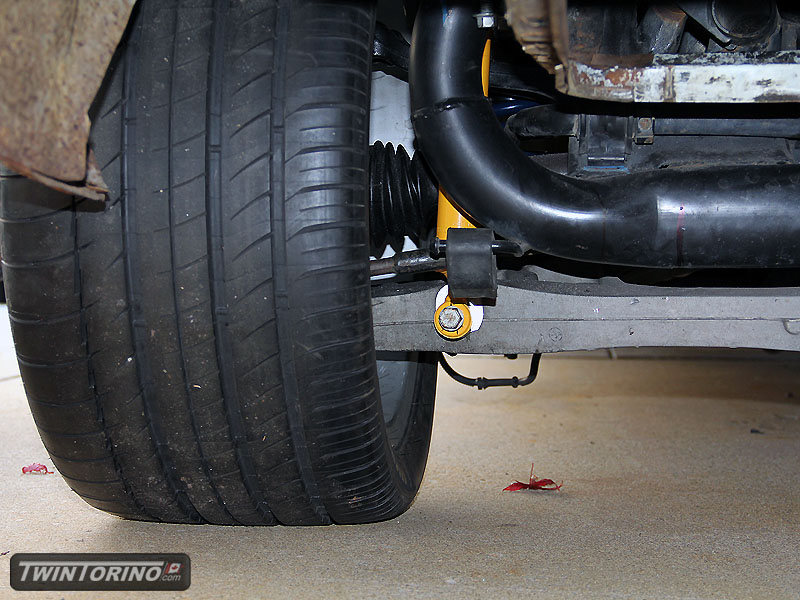

Design position – this is the position the car naturally sits at full of fluids on the ground. To fine tune the ride height, we opted to use 60mm ride height adjusters made by AST – yet other BMW part. Based on the second picture – you can see that the helper springs are full compressed and the entire weight of the car is now in the springs. To get the car at the correct height was a combination of spring length selection (since the rate was fixed to achieve a certain ride frequency), helper spring height, coil spacer height, and ride height adjuster overall height. The goal was to have the height adjusters at their midpoint at design position (which they actually sit at although not shown in the picture).

Jounce position – this is with the wheel pushed all the way up and riding on the jounce bumpers, which in this case are built into the shocks. Couple of issues you have to watch out for here – coil bind on the springs, control arm contact to the frame, and upper and lower spring seat misalignment. For the purpose of illustration, I stuck another spring on the car as compressing the other springs would require anchoring the car to the ground.

With all this in place and all the issues worked out (for now), the rear suspension design is complete and just needs to be final welded in place. This will make the process much easier on car #2.

Only thing left in the rear suspension area now are the brake line routing and getting all the ABS parts in place.