Category: Transmission

Trans access..

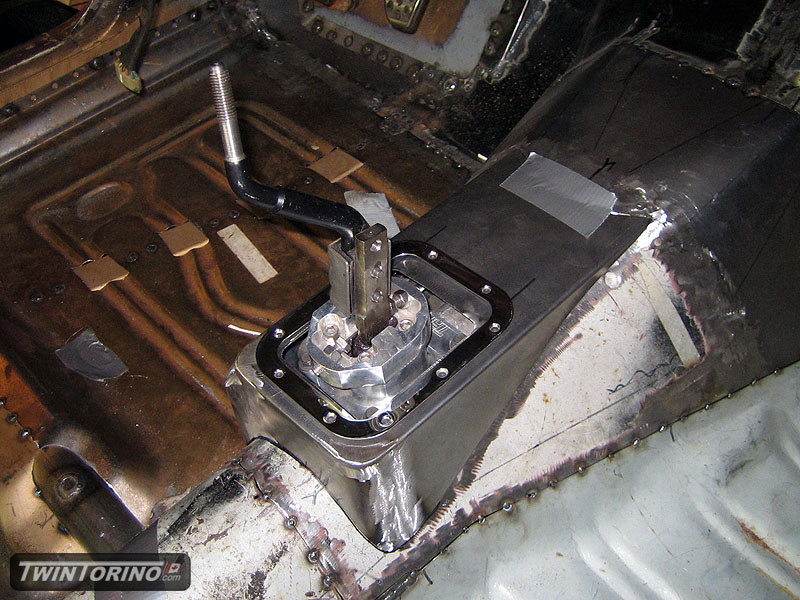

And now with the trans in place.. get a great view of the “hard to reach” trans bolts, which are now a breeze to get at. Just have to move the carpet out of the way.. and don’t even need to touch the heater box.

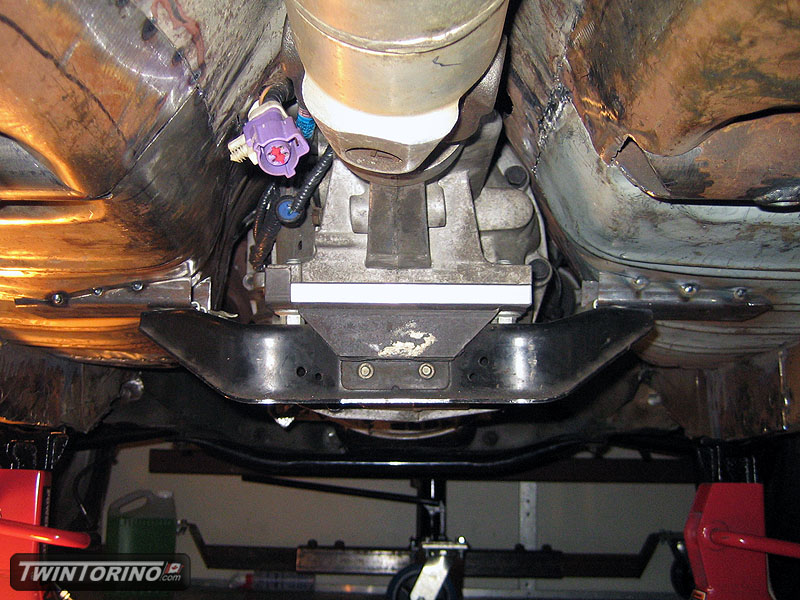

T56 mount..

Made some more headway this eve.. trans mounts – check. Had to make up a 1/2 aluminum spacer to be able to get j-nuts under the mounts. The crossmember is from a 2004 Cobra with T56.

Trans mounts and driveshaft

Over the weekend managed to wrap up the shifter hump which is now ready to weld in. Surprisingly the shifter lands right where it is supposed to. We put the Sparco seat with all the pedals and steering wheel in position and everything feels great. Should be fun to drive (and comfortable).

With the steering all hooked up, we were able to steer the front wheels for the first time – another big hurdle out of the way. There is absolutely no play in the steering which is a big change from before. Now just need to modify the good steering column and get it ready to go in for good. Only thing left to do on the column is make up an adapter harness to plug into the newer Mustang electronics.

Moved onto getting the trans permanently mounted in the car. We are just going to weld two brackets to the floor (still need to be trimmed down), and use J-clips to retain the trans mount to the brackets (similar to a base Mustang). With the subframe connectors in place and the seat supports, the floor is now very stiff. Keeps things simple and helps keep the weight down.

With the trans now in position, everything clears the trans tunnel, including the Police package Crown Vic driveshaft, which is the perfect length.

Now onto the fuel and brake system.

Firewall Fab and Driveshafts

Jumping all over the place lately as far as different parts of the car goes.

Finally got the last of the firewall out.. had to remove the upper lip that ties into the cowl (gets rid of the 1″ or so overhang too which is good). Kinda doing the opposite to what most people do when they remove the cowl panel :). Actually got a chance to put the stretcher shrinker to work since the upper lip of the firewall is curved. Have the drivers side almost ready to weld to the firewall.. just have to work on the pass side.

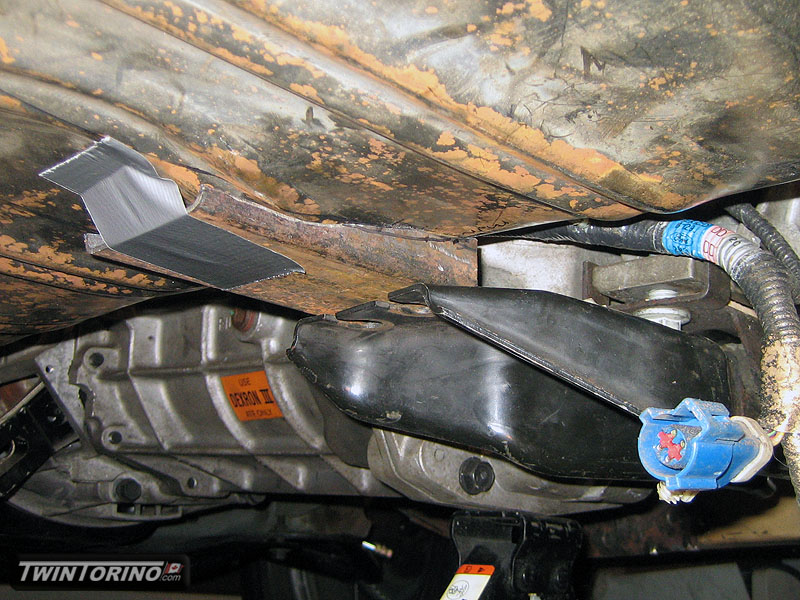

Next onto the driveshaft. Special thanks to MZ 500 on this one.. as I am recycling the driveshaft from his Crown Vic brake swap. Believe it or not, it is the perfect length for our setup. Just had to swap out the slip yoke as the T56 uses the only 27 spline shaft in Ford’s trans lineup (since it is a GM based trans). Has just enough clearance to the tunnel as well. Now that it is in.. time to get the tunnel made up. We have the rough shape made up.. just need to get it made out of sheetmetal. Note the difference in length from the Mustang one.

T56 #2 Nears Completion

Almost have transmission #2 done. Not much new as far as pictures go.. as the trans is exactly the same as the other.

I bought this one from a guy in Ohio for very cheap.. he was fed up with the way it shifted and had brought it into the dealer to take a look. The dealer pulled it apart and found the stamped keys destroyed and pieces were all over the magnets (just like the other one we have). The blocker rings (shown below) were warn out and then some. Thankfully they did not wear down more or my gears would have been chewed up. At this point – I am guessing the dealer found it would be cheaper to just replace it, so they did. They quickly pieced it back together (leaving several key pieces out) and that is how I bought it.

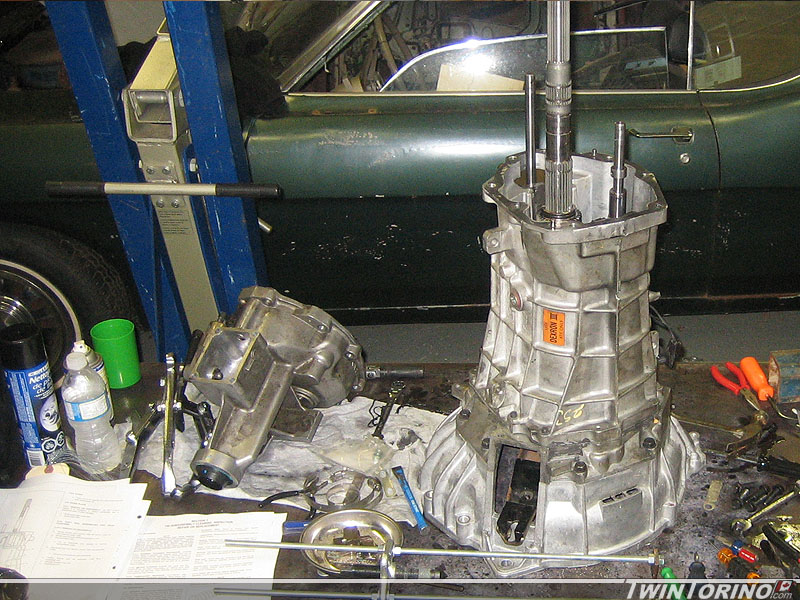

Here is a pic of everything disassembled and in the parts washer. Still amazed they can actually make these thing work.

T56 #1 Complete

Finished transmission #1 this evening.. and #2 is ready to tear down. Finally getting to the fun stuff. Process was quite straightforward being the first time we had done a modern trans.

Car was not going anywhere with this shaft. Ebay $13 replacement will do the trick. I will not be running enough power to replicate this failure.

Ebay used press coming in handy..

New sycro billet keys and blocker rings installed and ready to go:

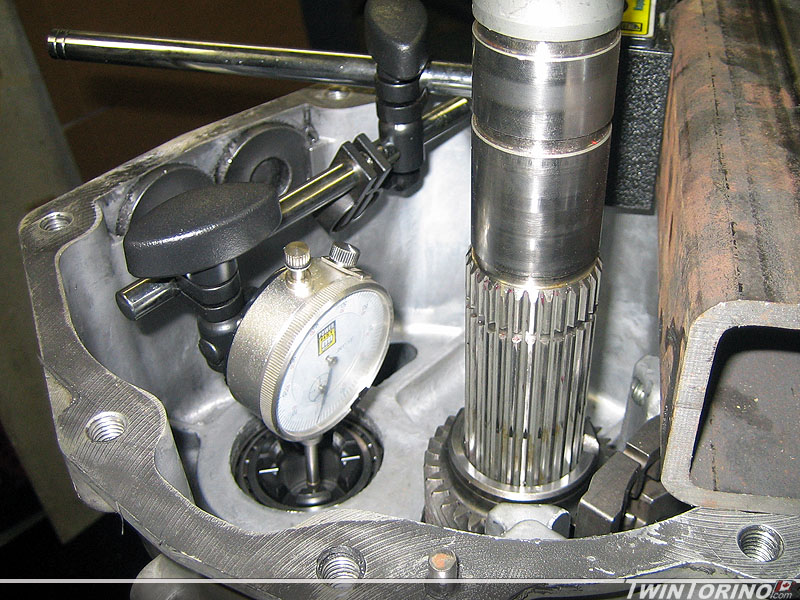

Measuring shaft preloads (since they use tapered roller bearings) and added shims to get 0.000 end play.

All done, cleaned up and ready to install:

Trans #2 ready to tear down. This one should go much faster.

T56 Carnage..

Tonights theme was Tremec T56 6-speed trans rebuild. We bought 2 of these knowing there was some internal damage, but the price was right. Symptoms were hard to shift into 3/4 gears, and also the transmission was popping out of 3rd and 4th while driving. This is a classic symptom in these transmission of failed stamped steel keys in the trans. This is a faily easy job as long as you have gear pullers available and heavy duty snap ring pliers. Another evening we should have this one cleaned up/rebuild and another torn down.

As you can see below – the fragments found in the trans of the stamped steel keys, what the stamped steel keys originally looked like, and the upgraded billet keys. Also the difference between the bronze shift fork pads and the plastic originals (the other ones were in pieces all through the trans). Transmissions will also receive carbon kevlar synchronizer rings and an upgraded steel shift fork (from aluminum). Otherwise all the gears in the trans were in great shape with no noticeable wear.

Engine and Transmission Positions..

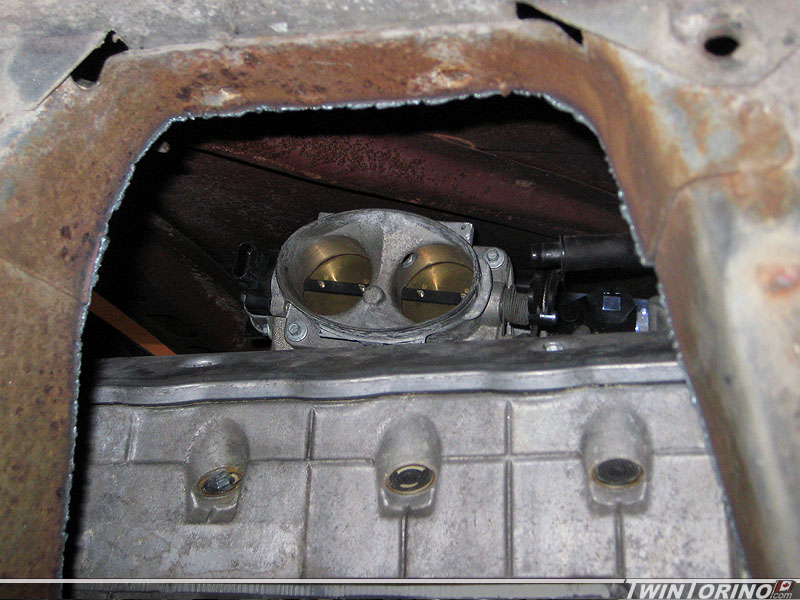

Managed to get the powertrain in it’s actual position this week. Finally starting to feel like a car now. Put the hood on to find that we actually have hood clearance which we were not really sure about it. Have around 15-20mm from the throttle body to the hood. Won’t need to modify the hood thankfully. Still detaing on whether to run a shaker. Kinda leaning towards not using it and keeping the stock hood. The engine ended up 4″ rearward of the front suspension in comparison to an SN95 Mustang.

Also got the 6-speed in. After struggling with getting it to work with the stock trans tunnel – it was clear that it was not going to fit. The plasma cutter made that go away quickly – A new custom tunnel will be made up. Otherwise, the shifter is in the perfect location and feels great going through the gears. The handle shown is just for mockup – I will likely modify a hurst shifter or something like that and then use a custom boot.

Now time to get the firewall finished up and get the floors and subframe connectors installed and welded up.

T56 Transmission Rebuild Time..

It is finally transmission rebuild time. Since we both bought known broken transmissions (to save money of course) we knew we would have to rebuild these anyway. We decided to upgrade the known weak points in the T56 transmission since these cars will see some track duty. The kit upgrades the trans with carbon kevlar synchronizer rings and replaces all of the typical wear items. There are two main weak points inside the case: 1) The stamped 1-2 and 3-4 keys are being replaced with billet ones as shown below. 2) The aluminum 3-4 shift forks are being replaced with steel pieces (from a Viper trans), and also replaced the plastic fork pads with brass ones.