Category: Firewall

Rotisserie ready to build

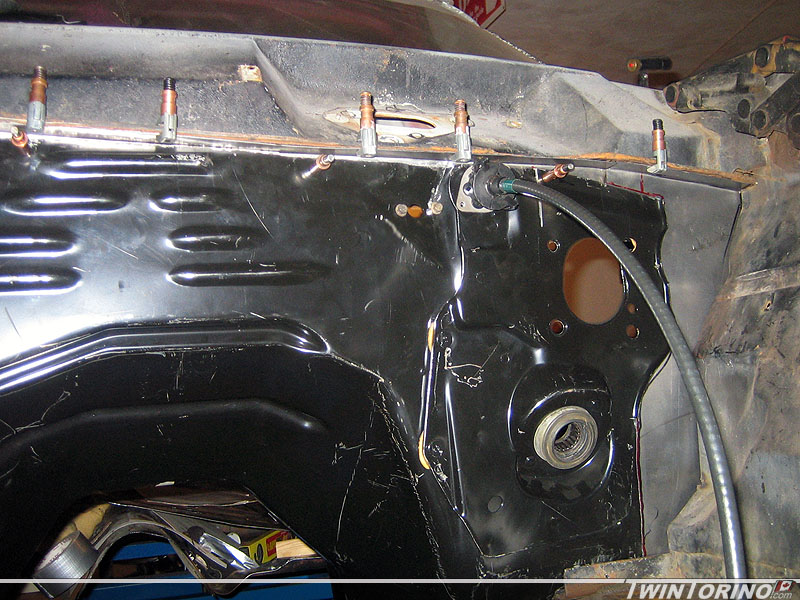

Made some more progress on the front suspension/firewall. Pass side firewall is now near completion and mates up nicely with the torque boxes (easier said that done). After that, the rear closeout was welded in for good, and then the strut tower was tacked in too. Will finish welding up the tower and then weld in the k-member this week. After that – front suspension is basically done except for the swaybar setup which should be fairly easy anyway. It will be based off a Mustang one.

Moving on the rear IRS once again, we bent up some 1/8″ brackets for the rear mounts. Have the pass side mount almost ready to go. Just need to get some crush sleeves made up for the frame and these will be ready to weld in for good. May be hoping in getting the car back onto the ground for the end of the month. This means car #2 can begin. This also leads to the next step which you can see below.

Almost ready to build the rotisserie. Finally have the design near complete. Casters are ordered, I have the hydraulic jacks from when they went on sale last week, and also have a bearing/housing setup that I found kicking around. Just need to grab the steel. Rotating part is based on a std. trailer spindle which make things cheap and easy to find parts for. Also makes it easy to seal things up for bringing near the sandblaster etc. We will just run dynamic trailer seals on both side of the bearing. Worm gear setup on the end is from a Harbor Freight winch. Made this up in Solidworks 2010 – CAD sure has come a long way. Have this designed so it will pick the car up off the chassis fixture (remove the center section and add the 3rd set of wheels).

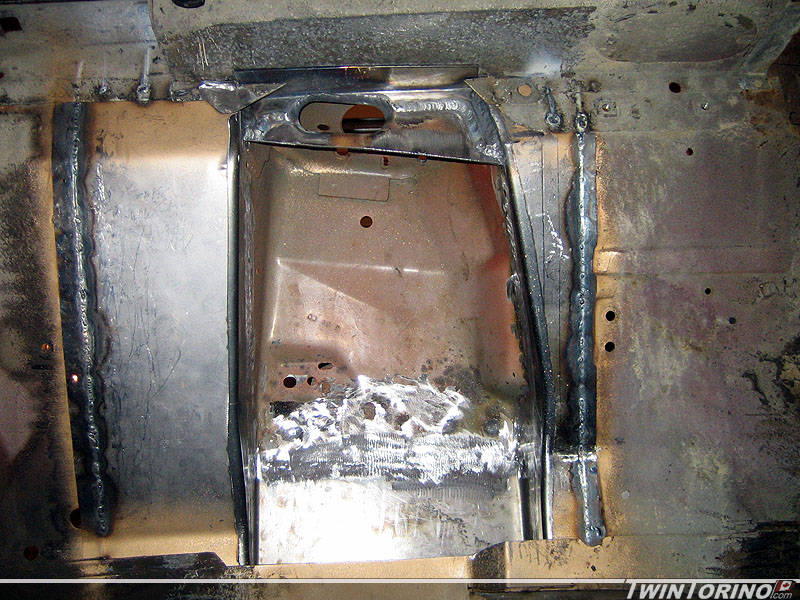

Hole through the car..

Started pulling everything apart before the re-welding begins. This one definitely screamed Kodak moment. This is a close to a skeleton as it will go. Will be a nice picture to look back on. The car sure looks bad like this :). Thankfully this will now fill in really quickly.

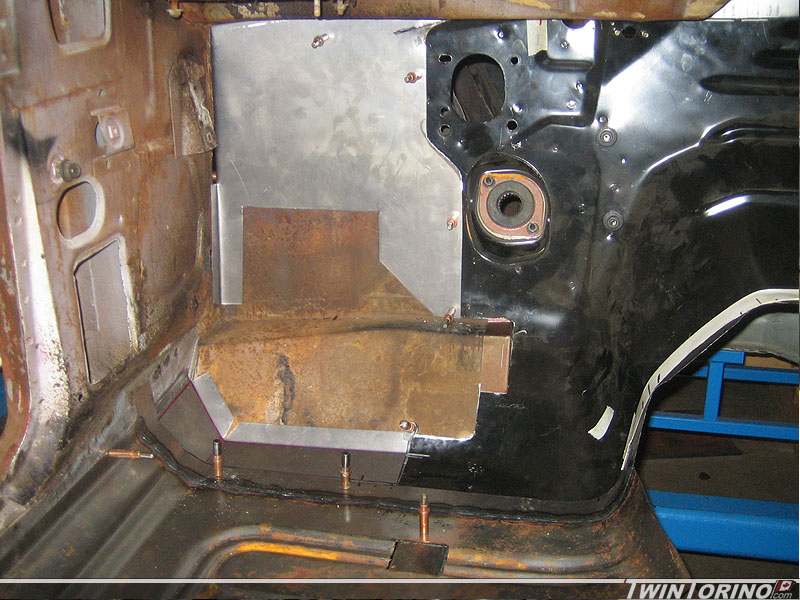

Finally have the drivers side strut tower completed and ready to weld in. Got the stiffener plate welded on and have all the close-out panels welded in and ready to go. Hope to finish the pass side one this week and get them welded in for good. Only a year behind schedule on these :).

Firewall Continues..

Finally some more progress here. There is and end in sight with the firewall mods. Almost getting ready to weld everything together and then weld it into the car. Once it is done it will be great as everything will bolt right in. Not sure what it would have looked like if we kept the original on there. Once everything is painted black should blend much better. Just need to extend the pass side floorpan and the fab work will be done for here.

Rather than double up the material near the torque box, we figured we would just use them as is. Save a bit of material and make the process easier.

Firewall Fab and Driveshafts

Jumping all over the place lately as far as different parts of the car goes.

Finally got the last of the firewall out.. had to remove the upper lip that ties into the cowl (gets rid of the 1″ or so overhang too which is good). Kinda doing the opposite to what most people do when they remove the cowl panel :). Actually got a chance to put the stretcher shrinker to work since the upper lip of the firewall is curved. Have the drivers side almost ready to weld to the firewall.. just have to work on the pass side.

Next onto the driveshaft. Special thanks to MZ 500 on this one.. as I am recycling the driveshaft from his Crown Vic brake swap. Believe it or not, it is the perfect length for our setup. Just had to swap out the slip yoke as the T56 uses the only 27 spline shaft in Ford’s trans lineup (since it is a GM based trans). Has just enough clearance to the tunnel as well. Now that it is in.. time to get the tunnel made up. We have the rough shape made up.. just need to get it made out of sheetmetal. Note the difference in length from the Mustang one.

See ya Later Firewall..

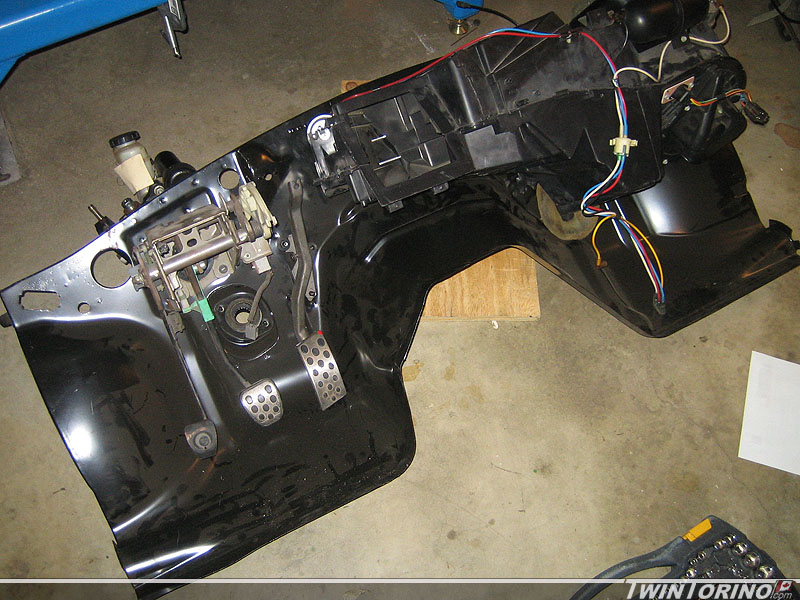

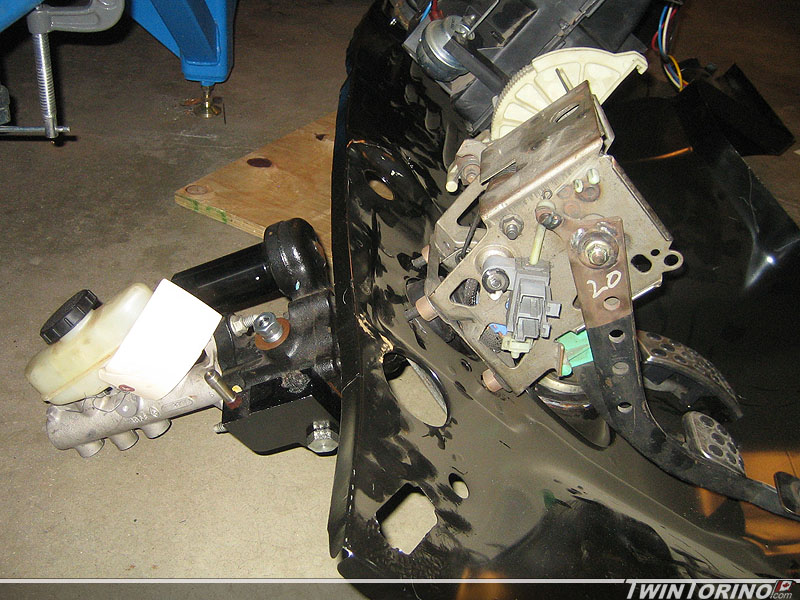

Too late to turn back now. Firewall is now gone and there is now a large hole in the car :). Surprisingly, with only some slight removal of material from the Mustang firewall, the piece started to fit up quite nicely. It will obviously need material added in certain places since the Mustang is a diffrerent size vehicle altogether. Started to install parts to see how they fit into the package and everything is finally falling into place. Pedals, hydroboost, steering shaft and heater box were all installed. Next the trans will be installed so we can see what is going to have the happen to the trans hump if anything. With the engine in, everything also fits nicely. The throttle and clutch cables also worked out quite nicely. The pedal spacing is much better compared to stock as well. Not sure what the pedal pads will look like in the end, but for now they will retain the 2004 SVT Cobra look.

MUstang Firewall and Brakes..

After going back and forth on how to make these pedals work out, along with the clutch cable, gas pedal & cable, heater box, wiring harnesses, steering column pass through etc. etc, we can to the conclusion that the firewall would likely be hacked to pieces by the time we got done with it. If only we had a firewall from a Mustang. We had two that were already part of a complete car, but those have lots of other pieces spot welded to them and they would likely be ruined trying to get the out, let alone how long it would take. I put a call into a friend who works at a dealer, and the next thing I know he was telling me that firewalls are available and are cheap! I guess when you think about it – how often would a firewall be replaced? Are car would likely be written off before needing to replace one. As you can see below – everything wil bolt up nicely and look like it was supposed to be there. Obviously this is not a quick bolt on modification and will require lots of cutting and welding, but it will be worth it in the end for sure. In the end, the cost of the firewall was less than 2 replacement Torino toe pans, so this was a no brainer.