Category: Engine

Cut out strut towers..

Finally got back to the project again now that the new Torino and parts are sorted out.

Cut the front strut towers out of the ’04 Mustang (definitely not up there with the most fun activities to date). After they were out, we needed to drill out spot welds and cut off what we don’t need to fit in the Torino. We also cut out the remaining pieces of the stock shock tower in the Torino. The last picture shows a quick mockup. Still need to trim off some material and determine where they have to go exactly. Very pleased with initial fitting – they actually look like they are supposed to be there. Believe it or not, the Torino and Mustang engine compartments are the exact same width (to an 1/8″), and the angle of the sheetmetal in the Torino in front of the strut tower exactly matches the Mustang so they should blend in nicely. The goal is to make it look like they were supposed to be there. Hope to get them fit in better tomorrow night.

New Roush Engines..

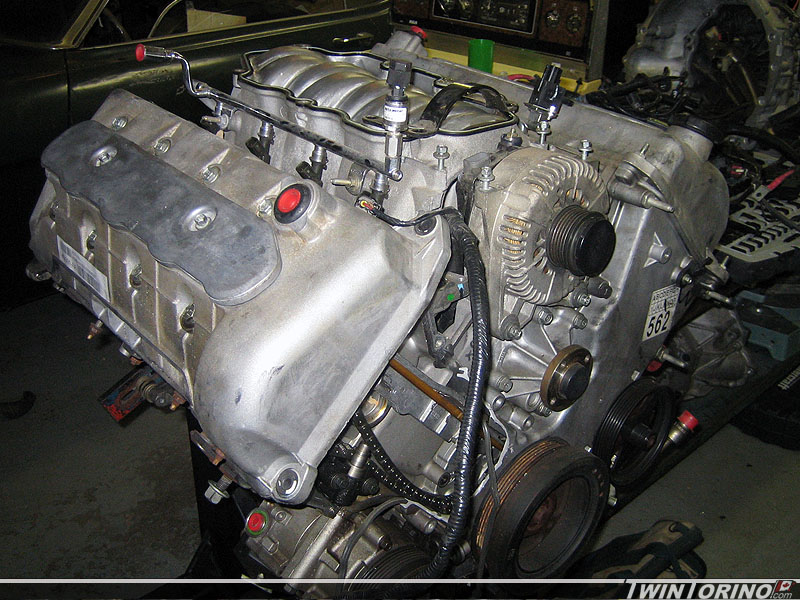

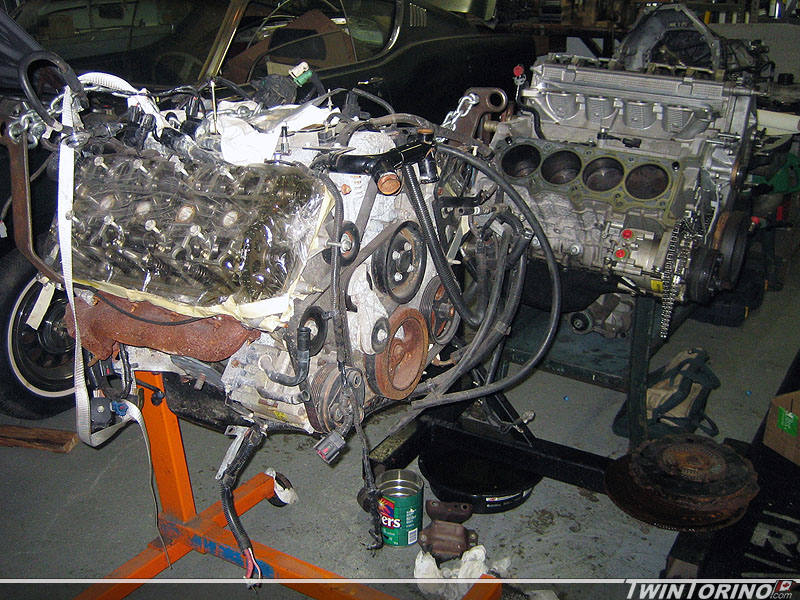

Slight change in powertrain plans here.. have had one of these engines for a while now, and recently found a second one (both used of course). Could not pass up the deal on them. They are 4.6L 2V engines that use an Eaton M90 supercharger and were designed for use in a 2001-2004 Roush Stage 3 Mustang. Both setups are missing some parts and will require some custom fab to make fit.. but nothing too major. Should be good for over 400hp/400ftlb of torque and will still get great gas mileage (when not under boost at least). The rest of the powertrain is good for 500ish hp so we should be OK there. Two main concerns with this were hood clearance and alternator clearance to framerail. After mocking things up both seem within reason, so I think we are going ahead with it. They will add a bit of weight to the car which is not overly desirable.. but what can you do. The Mach motors will go on the shelf until the next project I guess. I’ll let the pictures tell the rest of the story…

Mach 4V Rebuild..

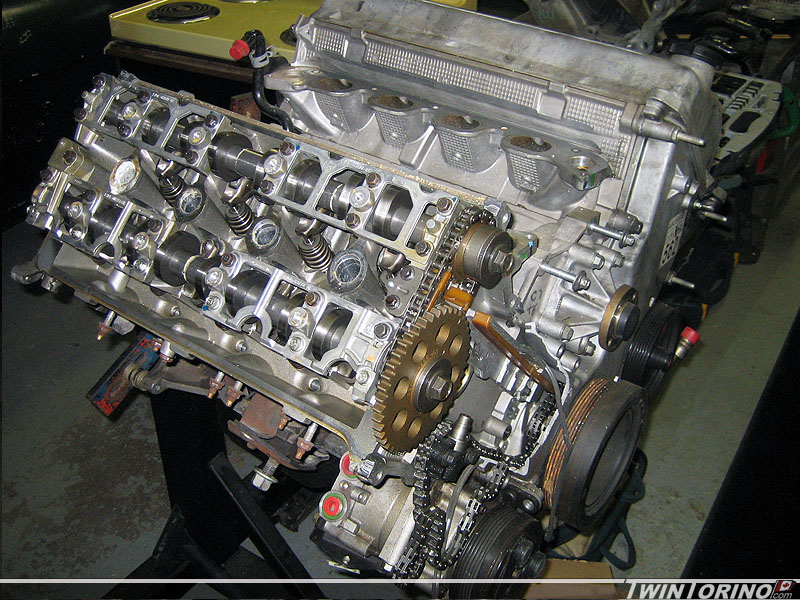

Finally time to start working on the fun part of this project – the powertrain. We have 2 kits to completely rebuild and upgrade the 6-speed transmissions, and the engines will just get a refreshing/upgrade and make sure everything is OK inside. After all, they are only 5 years old.

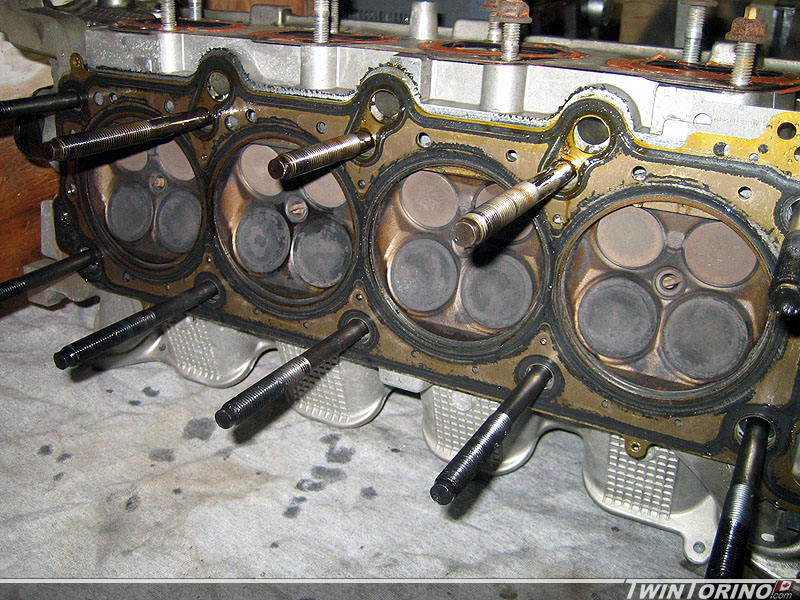

One of the engines we bought came from a car that was a write-off and have some issues with the front cover being cracked as you can see. We took a risk on this (since we only have pics to go by) and hoped that there was no internal damage from the timing chain coming off. Sure enough when we pulled the head off, all was well inside. Gotta love the 4 valve heads :).

Engine and Transmission Positions..

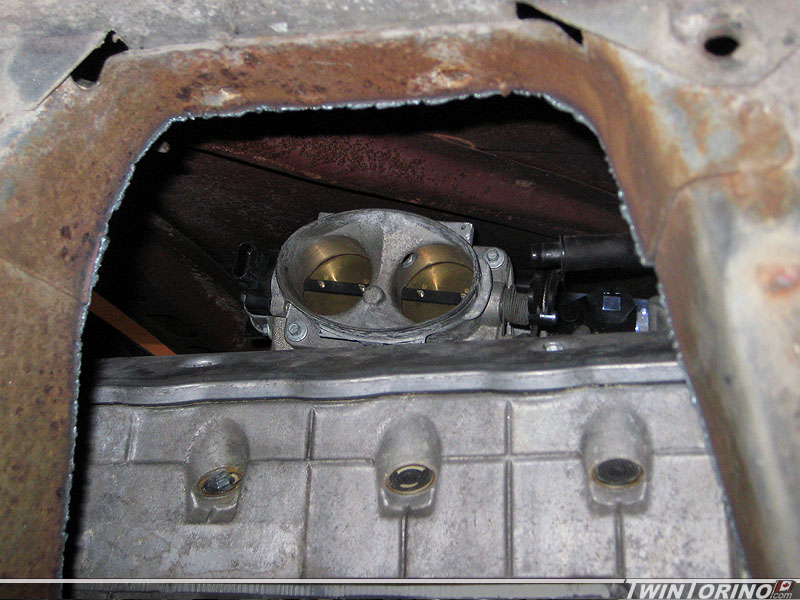

Managed to get the powertrain in it’s actual position this week. Finally starting to feel like a car now. Put the hood on to find that we actually have hood clearance which we were not really sure about it. Have around 15-20mm from the throttle body to the hood. Won’t need to modify the hood thankfully. Still detaing on whether to run a shaker. Kinda leaning towards not using it and keeping the stock hood. The engine ended up 4″ rearward of the front suspension in comparison to an SN95 Mustang.

Also got the 6-speed in. After struggling with getting it to work with the stock trans tunnel – it was clear that it was not going to fit. The plasma cutter made that go away quickly – A new custom tunnel will be made up. Otherwise, the shifter is in the perfect location and feels great going through the gears. The handle shown is just for mockup – I will likely modify a hurst shifter or something like that and then use a custom boot.

Now time to get the firewall finished up and get the floors and subframe connectors installed and welded up.

IRS Bends and New Oilpan..

Starting to order up some of the parts required to rebuild the engine (or at least check it out) and then add part like oil pans that are spefically for road racing. We decided to get a Moroso pan that is specifically designed for use during on track events and has seprate trap doors to keep the sloshing to a minimum.

Also had the IRS tubes show up today which will allow us to complete the rear suspension install. These are 2.5″ x 1/8 wall tubes we had custom CNC mandrel bent for this application. They came out great as you can see.

Engine Trial in Vehicle..

Once the front shock towers were removed and the stock Mustang front suspension k-member was modified, the engine was placed in the car. Surprisingly, the engine and exhaust fit quite well, and should only require a few tweaks to make it work. This is a big relief as we had thought it was going to be necessary to widen the frame rails. The only thing that is really in the way is the old trans crossmember brackets which will be cut off anyway. The motor mounts on the crossmember will need to be adjusted as the engine needs to shift back at least 6″. Things are finally starting to move along now!

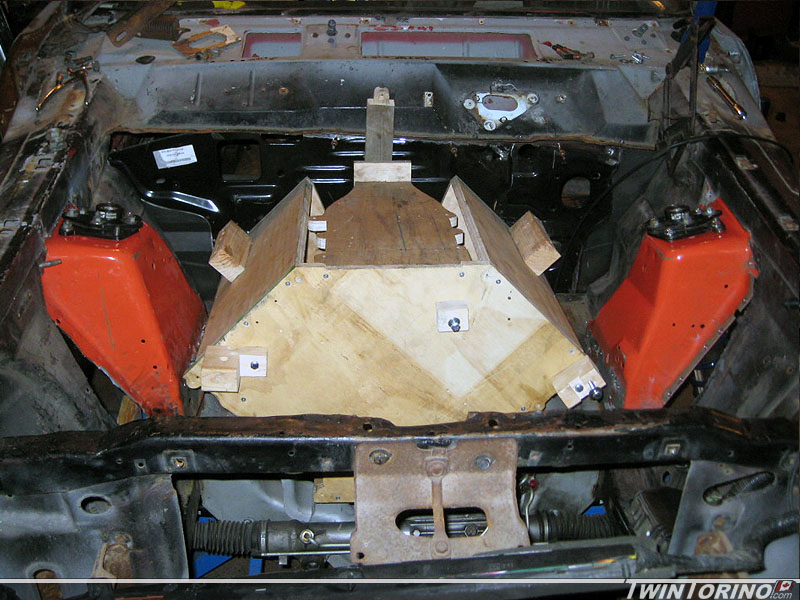

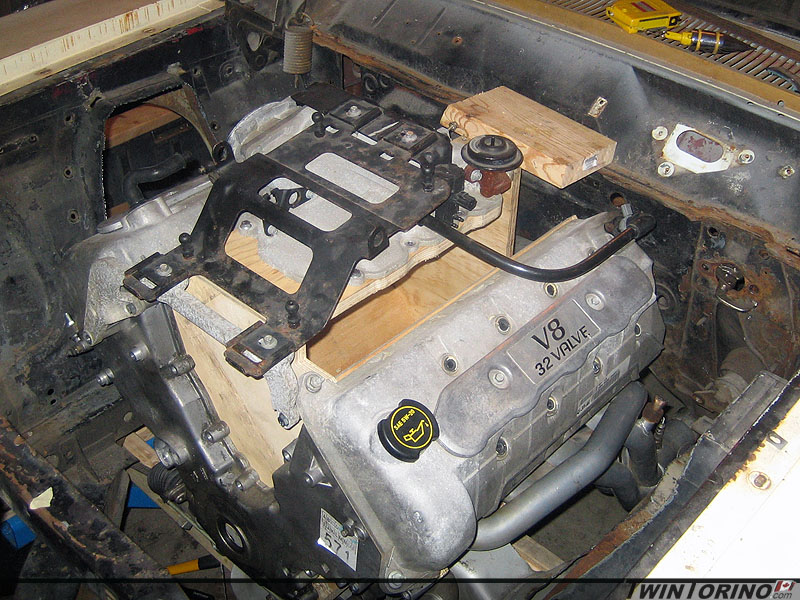

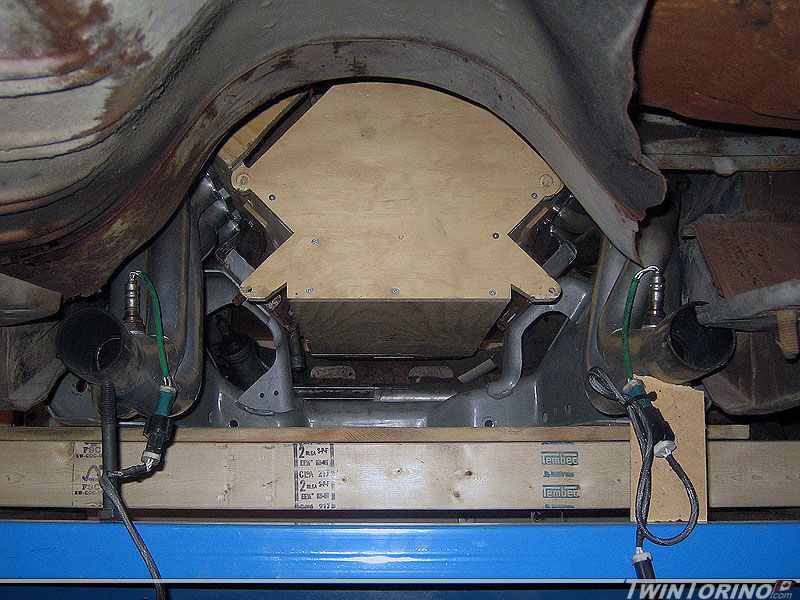

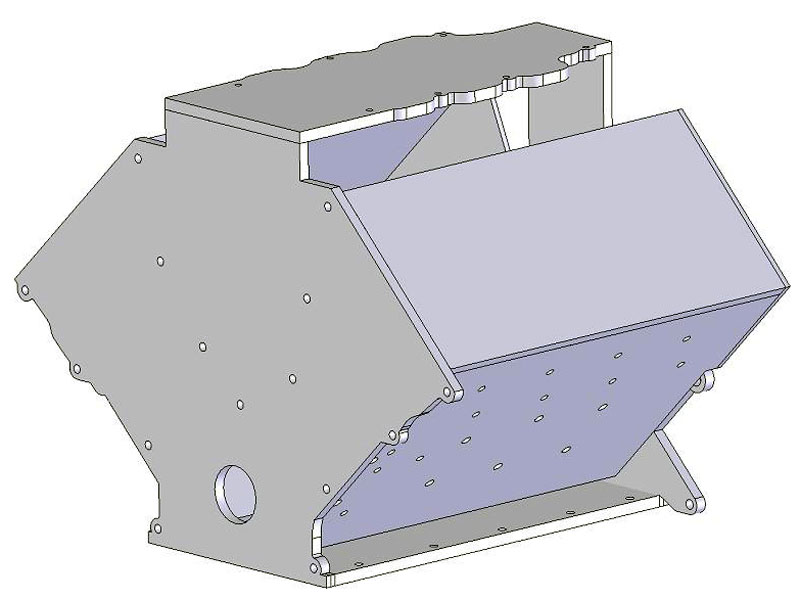

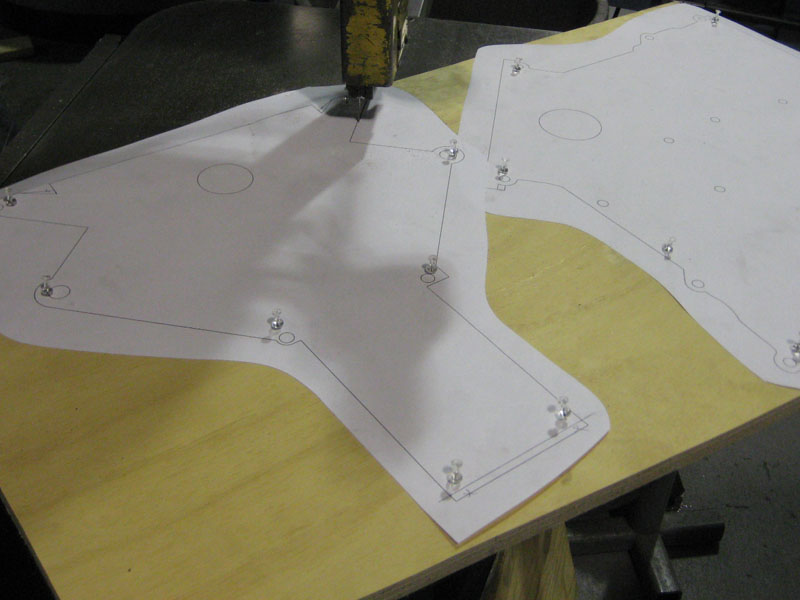

Making the Wooden Mockup..

Got tired of trying to mock up the underhood area with a complete heavy engine, so I decided to make something a little more lightweight. A heavy engine was even more annoying to work with the car on a jig that is 18″ off the ground. Since I am on a tight budget, I opted to use an old shipping crate and about $10 worth of fasteners from Home Depot. After careful measurements of the block and tracing out various components, a CAD model was created. This was then used to make up 1:1 scale prints, which were in turn pinned to 3/4 plywood and cut out. This allows the headers, cam covers, trans, front cover, upper intake manifold, manifolds, A/C compressor and power steering pump to be installed in the car.

The shaker on the 2004 Mach 1 sits very far forward when in the Torino, so I had to take it apart and shift it back about 8″ to make it look right. Not sure if I am going to keep it on the car or not. The engine does not like the factory shock towers as you can see – the cam covers won’t fit (as expected). The plasma will make them go away.

Making Room for the Powertrain..

If you look at the previous pictures, you will see that a DOHC engine was not meant to fit within Torino shock towers. Easy solution there – get rid of them. They will be replaced with 2004 Mustang based ones.

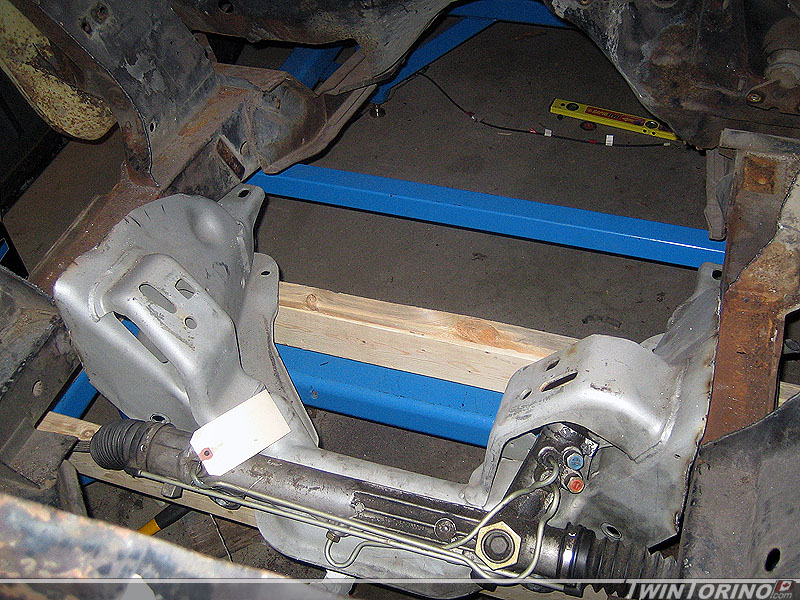

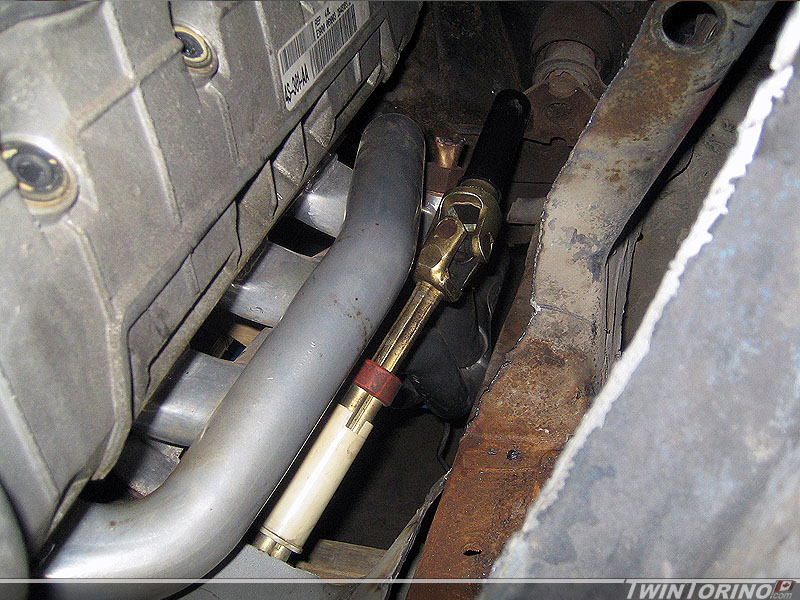

I will say once again how great a tool a plasma cutter is!! This is by far one of the best and fastest tools I own. It makes cutting up cars a breeze. Once the shock towers were out, the stock Mustang k-member was modified to allow it to bolt into the Torino. A spare mockup steering rack was placed in position and will work perfect once in place which is another relief as we were not sure if it would hit anything.