Category: Chassis

SF Connectors Done and New Parts..

Almost there..

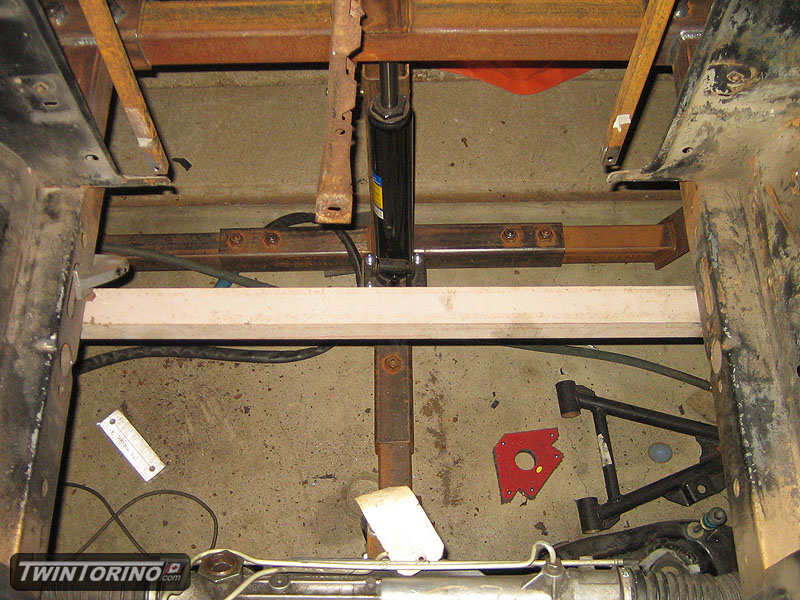

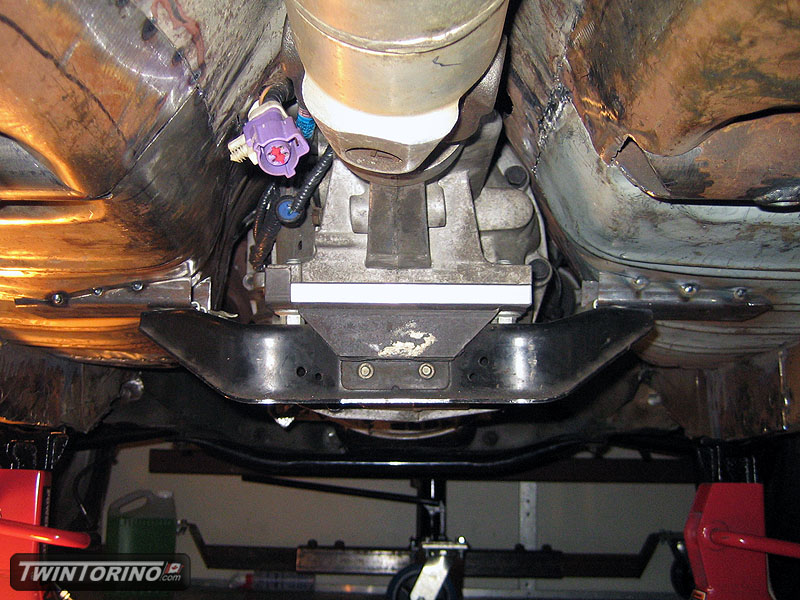

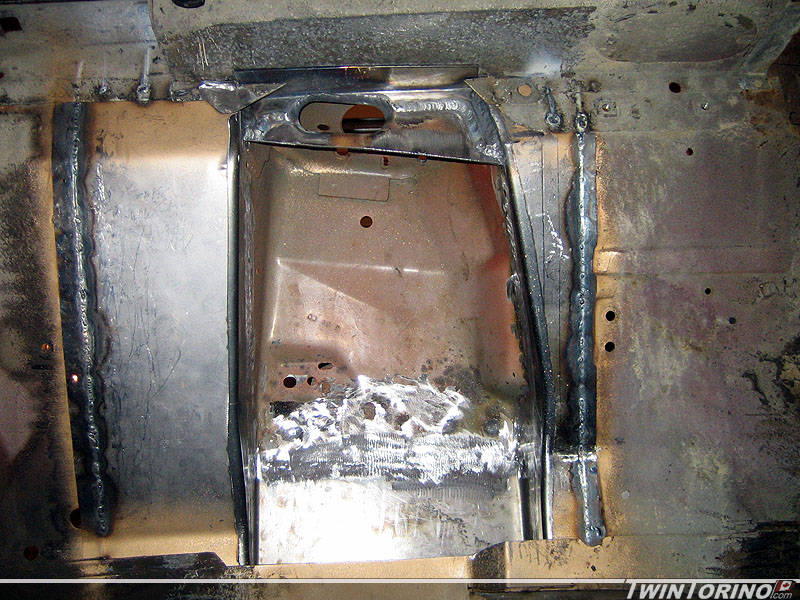

Have most of the underbody final welded (pass side shown from underneath car). Was a bunch of rust on the front crossmember under the rad – so we just cut it out. Will replace with 3″x2″ steel section which will fit perfectly – the nice thing is it only needs to be cut to length and can be welded in. No sense in spending lots of time on spot repair since the suspension points that use the underside of this are long gone anyway.

Also found an Earls oil cooler, Bosch intercooler pump and Spicer 1350 series u-joints on Ebay in the last few weeks. Just need to get a Speedway 36″ 1.25″ OD splined sway bar for the front and the major purchases for this car will be close to complete.

Welding and Exhaust..

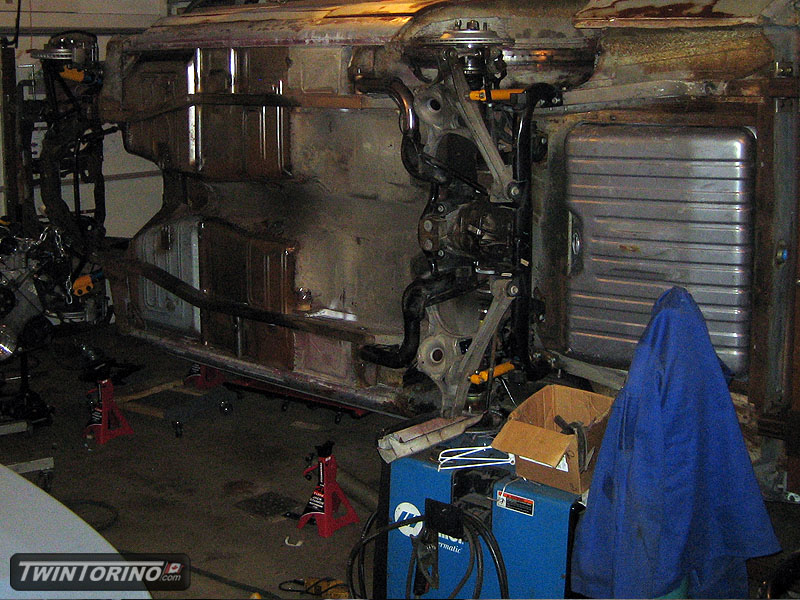

Been working a lot on the car lately.. mostly in the form of welding, so there is not as much to see as of late. Finished the balance of the welding on the subframe connectors in the rear and moved onto the rear suspension and wheel tubs. Should have that done in the next couple of weeks.

Finally gave the exhaust some attention. Decided to just run an “off the shelf” 2003/2004 Cobra system, and will add length where necessary, and modify the outlets so you can’t see them. Found a used 2004 Cobra cat-back stainless Magnaflow system with only 1600 miles on it for only $200 shipped, and it even came with an extra set of flowmasters. Not sure why it was so cheap, but I didn’t ask questions there. Have the forwards x-pipe section on it’s way, so we may have an exhaust system in the car soon enough.

More welding and rear suspension..

Have been doing lots of underbody welding.. so not a whole lot of exciting progress to see latetly.

Added the final pieces to the rear of the subframe connectors to make them blend into the rear frame rail. Once the IRS comes back out, this can be finished up. Also started to weld the connectors to the floor pans.

Now that the rosisserie is in use, we added the final bracket to the IRS in the middle of the car. These IRS units are notorious for wheel-hop issues, so hopefully stiffening all of this will put that to rest.

Coolers and SF Connectors..

Could only put it off so long.. finally had to buy some new parts for the car for a change. Working on getting the cooling, power steering, fuel and brake systems up and running. Wanted to have all the fittings in black and with black polyester weaving on the hoses. Took a while to track down all the parts for the right price, but we have everything now for one car.

Also got upgraded parts to run the remote oil cooler and also a better pump and Cobra pickup to keep the engine happy on the track.

Started cleaning up the underbody and began welding everything underneath. I am not sure how we would have done this without a rotisserie.

ABS and upside down car..

Finally finished up the worm gear setup on the rotisserie to allow the car to spin around and got to see what the rotisserie hype is all about. Sure is a nice tool to have around the garage! Unfortunately got carried away and forgot to drain the oil out of the diff. Now the garage has a wonderful 80/90 aroma.

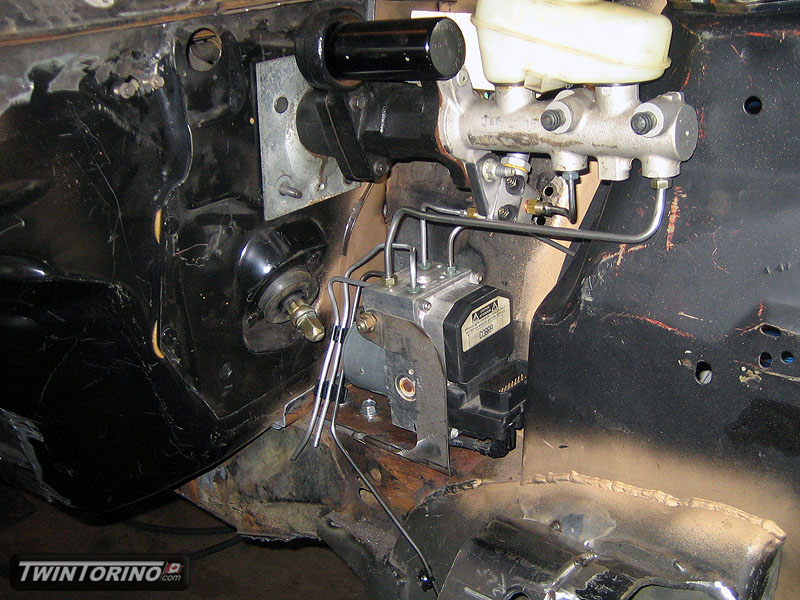

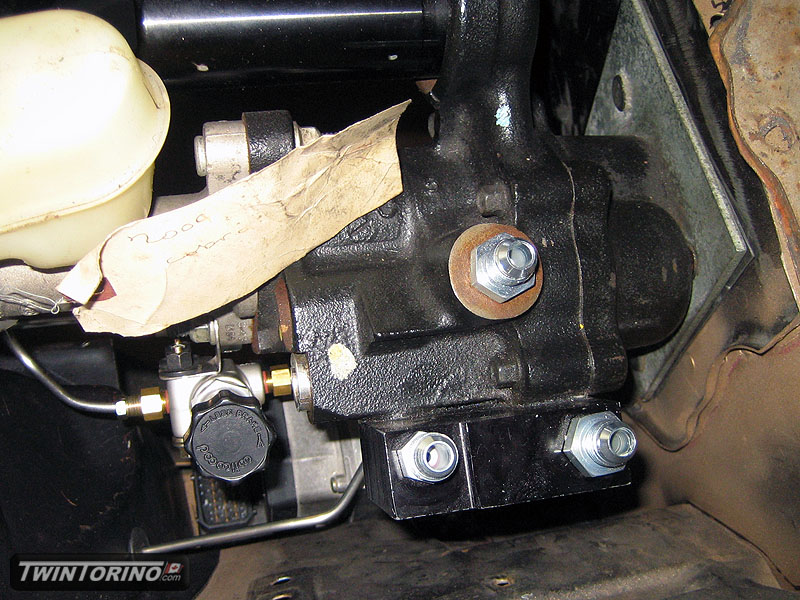

Moved on to getting the brakes in order. After searching far and wide for Torino brake line kits with ABS, we just ended up bending our own. Got the Wilwood proportioning valve in place, and also bent and flared up both front lines. Started routing the rear lines. We bent all of the lines up with 3/16 aliminum tube first which was 10x easier. Kinda looks like it was supposed to be there. Also got in the adapters to convert the hydroboost to AN style fittings.

T56 mount..

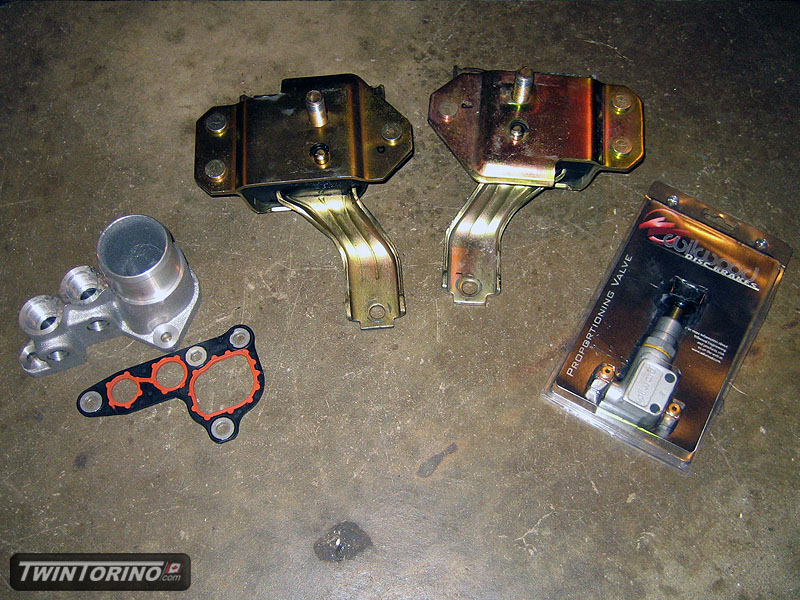

Made some more headway this eve.. trans mounts – check. Had to make up a 1/2 aluminum spacer to be able to get j-nuts under the mounts. The crossmember is from a 2004 Cobra with T56.

Minitubs..

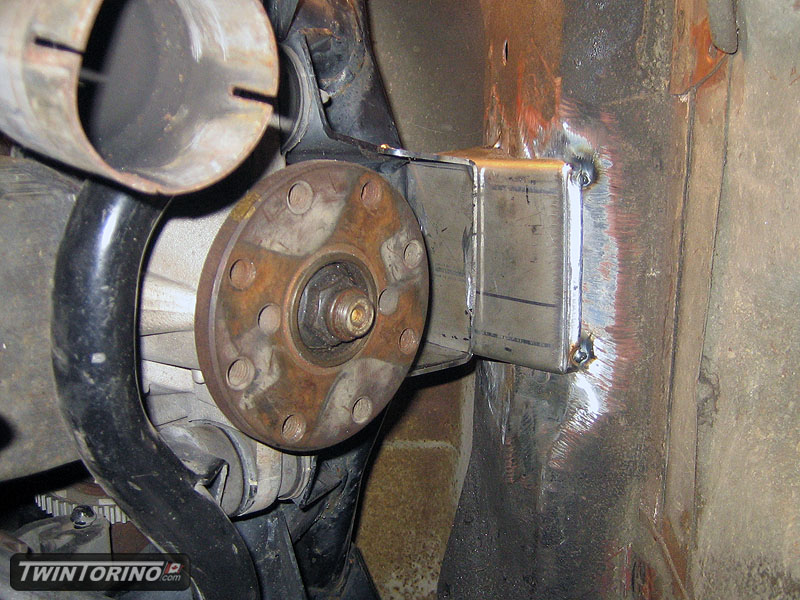

Managed to get some things done over the past month or so. Floors are in the car and basically done and now ready to weld in. Decided to move back to the rear suspension and things back together for good. First step was to add 1.5″ to the rear wheel wells to make them clear the tires, and then notch the frame out for the 2.75″ shock mount tubes. Once the shocks were in, we were able to confirm the shock jounce and rebound travel and everything looks OK clearance wise. Wheel wells are now tacked into place and ready for final welding. Sure would be nice if someone out there made Torino sheet metal parts :). Still lots of welding to do here, but getting much closer by the day.

Firewall, cooling module and more..

Suppose it is about time to post some updates. Making some decent progress lately.

Keeping in the theme of used parts.. picked up some more of them. Found a set of nearly new Energy Suspension 4.6L motor mounts and also a Wilwood proportioning valve. Had to buy the oil filter adater new though – the one from Ford Racing is a nice piece (M-6881-C). Planning on running a remote oil filter w/t-stat and also an oil cooler in front of the cooling module. This part also increase the block inlet hose to 2″ to further reduce the possibility of water pump cavitation.

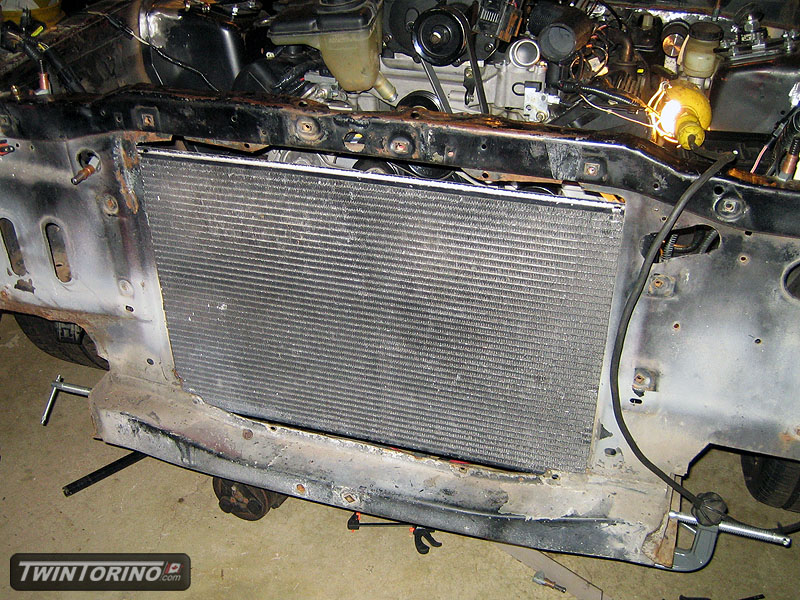

We made up custom radiator and condensor mounts which allow us to get them both between the frame rails to keep them as low as possible. This way the degas bottle can be mounted where it was intended to go and remain the highest point in the cooling system, but at the same time being low enough to clear the hood which is does nicely. All these parts are from a 2004 Cobra which uses a 36mm all aluminum radiator. All other Mustangs except the Mach 1 have plastic end tanks. A/C compressor is now in and the new Mustang heater box also fits on the firewall. Just need to run the lines and the A/C system will be complete.

The firewall has been completed and is ready to install along with the floor pans. Rear suspension is nearing completion and just needs to be final welded. The only thing missing in the pic is the upper coil spring retainer. ABS wiring is now in place. Last thing to do is run the hard lines which will come next.

As an aside – I had never used the wet toilet paper trick to remove a pilot bearing so I figured I would give it a try. I am used to the messy grease trick. Surprisiningly this worked like a charm and clean-up is a breeze. You sure can fit a lot of paper in there! Installed a resurfaced 2004 Cobra aluminum flywheel, clutch, pressure plate, throwout bearing and clutch cable. Trans side of things is ready to go. Just need to get the mounts in.

We put the car on the scales and put every part and piece we planned on putting on the car. Looks like the car will come in at around 3450lb curb weight (56%ft/44%rr). With driver and gear we are looking at around 3650lb track weight. We put the car in the air and measured all of the corner weights and using the motion ratios front and rear figured out what spring rates to use. We are using 2.5″ ID front springs and 60mm rear springs from Hypercoil. The target is to run a front ride frequency of ~1.55Hz and 1.7Hz in the rear for the street. For the track the ride frequencies will be similar front to rear.

Hole through the car..

Started pulling everything apart before the re-welding begins. This one definitely screamed Kodak moment. This is a close to a skeleton as it will go. Will be a nice picture to look back on. The car sure looks bad like this :). Thankfully this will now fill in really quickly.

Finally have the drivers side strut tower completed and ready to weld in. Got the stiffener plate welded on and have all the close-out panels welded in and ready to go. Hope to finish the pass side one this week and get them welded in for good. Only a year behind schedule on these :).

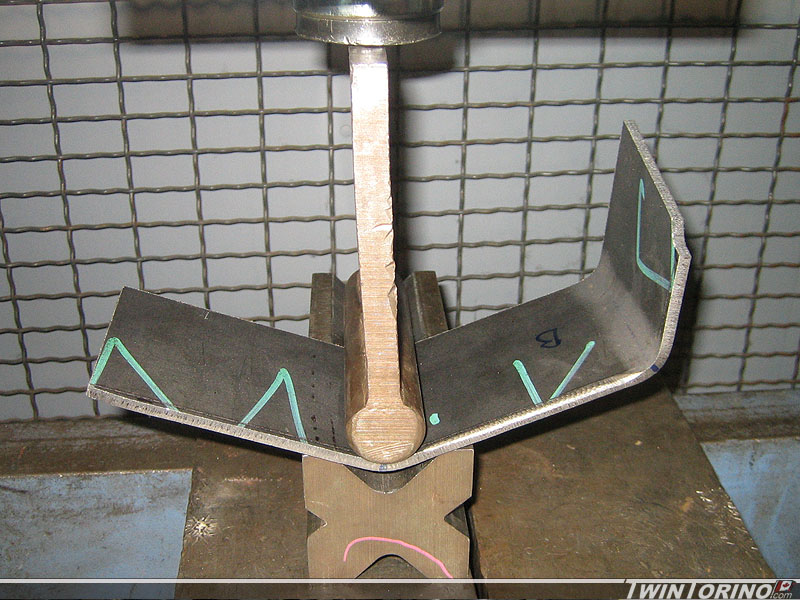

K-Member Engine Mounts and Wiring

Moving right along – have the Mustang K-member mounting tabs completed. Only thing left to do it shift the engine mounts back 3″ to get the engine as far back as possible. Since the steel on the stock mounts is 3/16″ thick, this means the std brake won’t cut it. Have to move the the hydraulic press for these bends. Got them ready to weld in over the weekend. Will get them welded in this week and then it is finally time to weld the front suspension permanently into the car.

Also found a complete vehicle wiring harness set from a Mustang GT and heater box / ducting parts.