Finally.. lots of free time to work away at things. Made up a shifter hump to conform to the carpet and clear the reverse lock-out solenoid on the transmission. Almost ready to cut the floor away and weld in. After that, floor fab is done and only needs to be final welded.

Found someone on Ebay selling oil thermostats cheap on Ebay so I grabbed a pair of them. These models are actually for a Lotus, but work fine with the Torino since it is set up for an oil filter with a 3/4-16 thread. You simply remove the oil filter and stack this on top and put the oil filter back on. Since we are running an external oil cooler, this is a must in order to let the oil in the engine get up to the proper temperature (same as a thermostat in the cooling system).

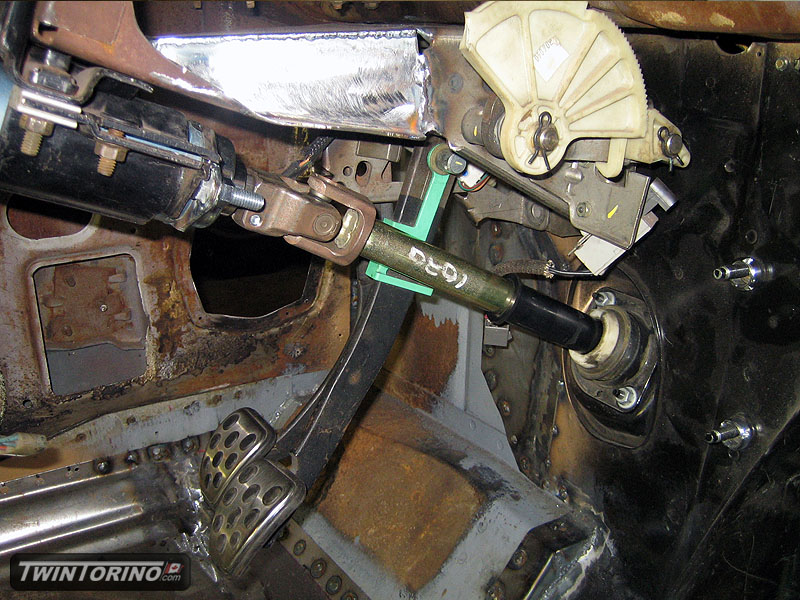

Moving onto the steering system, we found the necessary parts to make it work. The “trial” steering column was cut down considerably and a bracket was welded onto the end to accept a flange bearing. The inner shaft is then cut down to mate with the intermediate steering shaft. This shaft then connects to the lower shaft, which then connects to the rack. The steering colum has to be cut back so far to clear the brake pedal. This also reduces all of the u-joint angles. Believe it or not, these shafts are from a 2004 Lincoln Navigator ($20 on Ebay). The connection on the steering rack is a custom Ford only one, so this limited the choices to a Ford vehicle. Alternatively companies like Borgeson make the parts needed to put together all the shafts, but they are not cheap. Mustang ones will not work since the suspension is further forward. The firewall bearing is from a Mustang. For the first time in years – the Torino can once again be steered using the steering wheel.