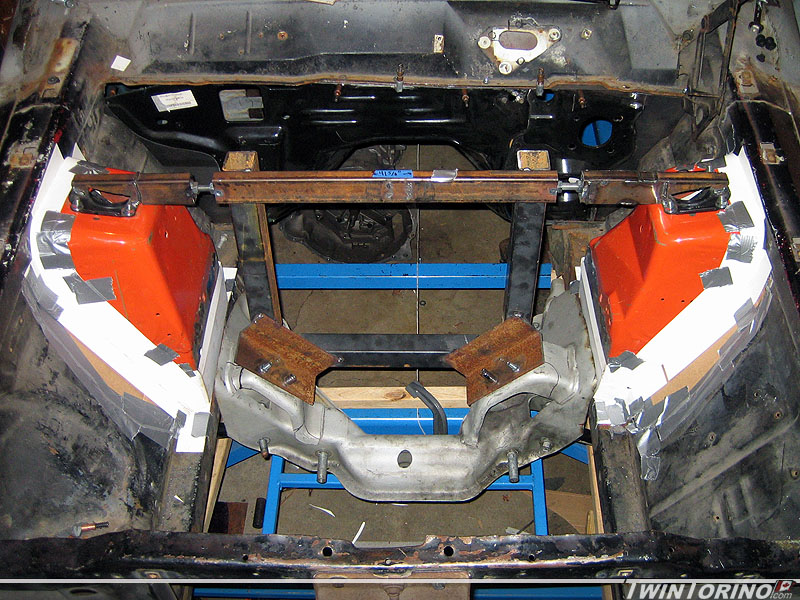

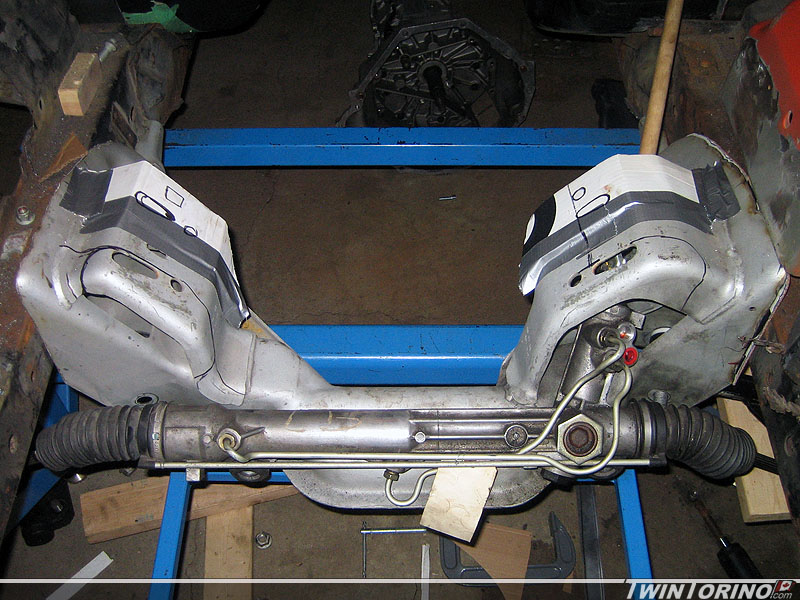

Got some more work done on the shock tower setup. Unfortunately with the Fox control arms being used, this also means the upper strut mount needs to move inboard to be able to get the alignment settings right. This meant we needed to cut up the jig and make it adjustable using threaded rods and nuts.

The goal here is to be able to set the front wheels to 2-3° of neg camber for the track, and then adjust them back to 0.5° neg camber for the street. The caster is also being increased relative to stock. Looks like 275’s will fit up front when using the 0.5° setting which is great news.

All that is needed to set things into position is to flip the camber plates upside down and swap side to side. This way they can be bolted to the jig. Next max the camber setting inboard and then take suspension measurements. Keep adjusting the fixture outboard until the max neg camber is achieved. After this, unbolt and put on shock towers. Lots more sheetmetal work ahead, but it should hopefully work out in the end. Turns out the inner surface of the shock towers is almost flush with the origional fram rail which make things easier fab wise.